![[Alt]](/upload/iblock/89f/i3233eqtknga8rhjdop5az2454x2q5h7.png)

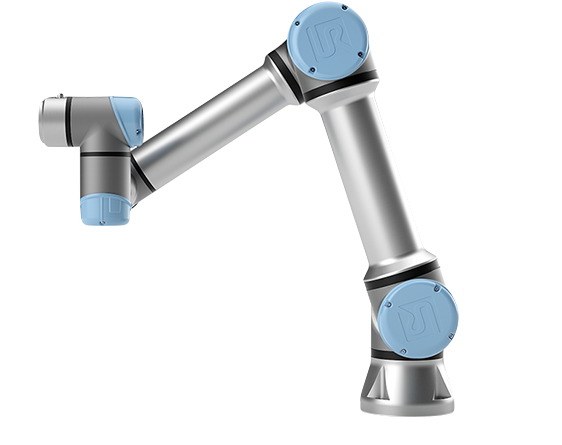

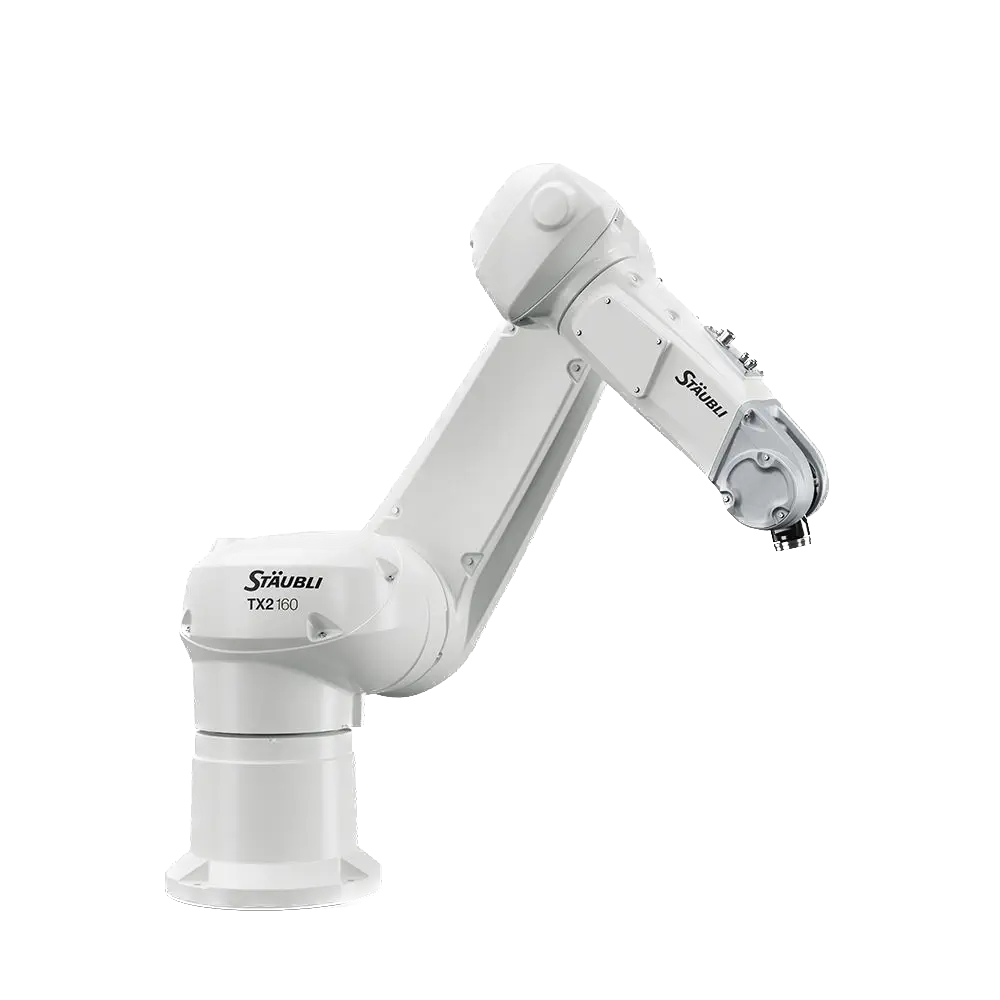

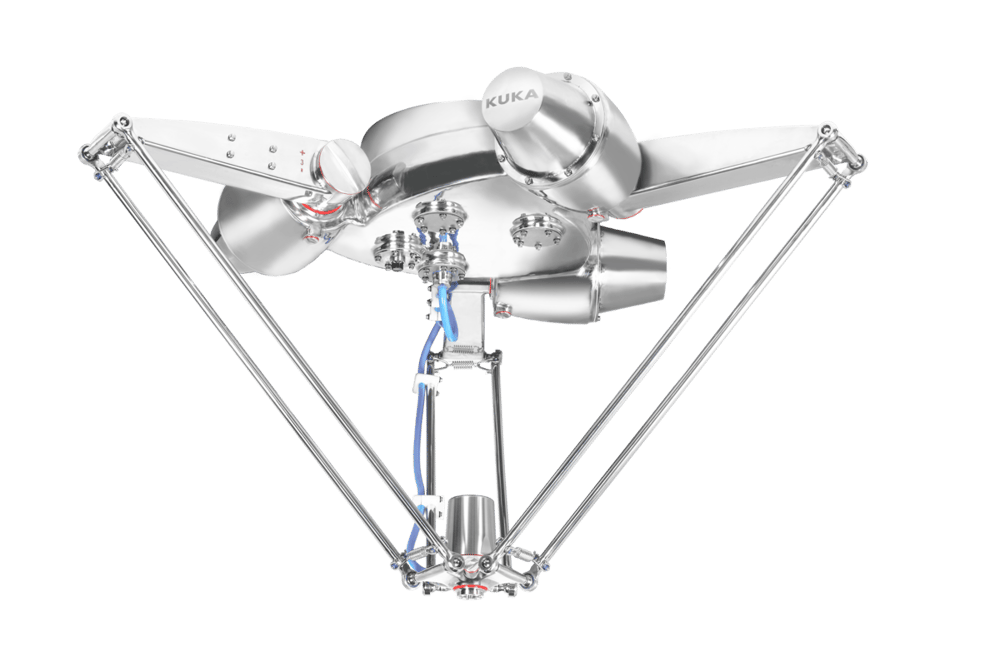

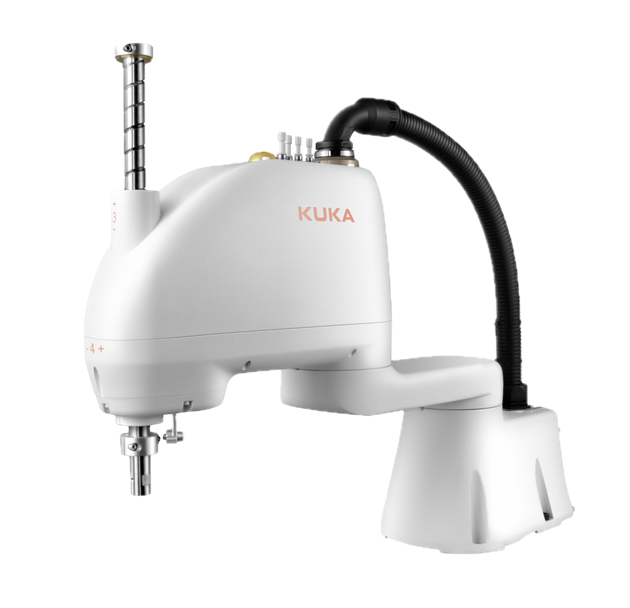

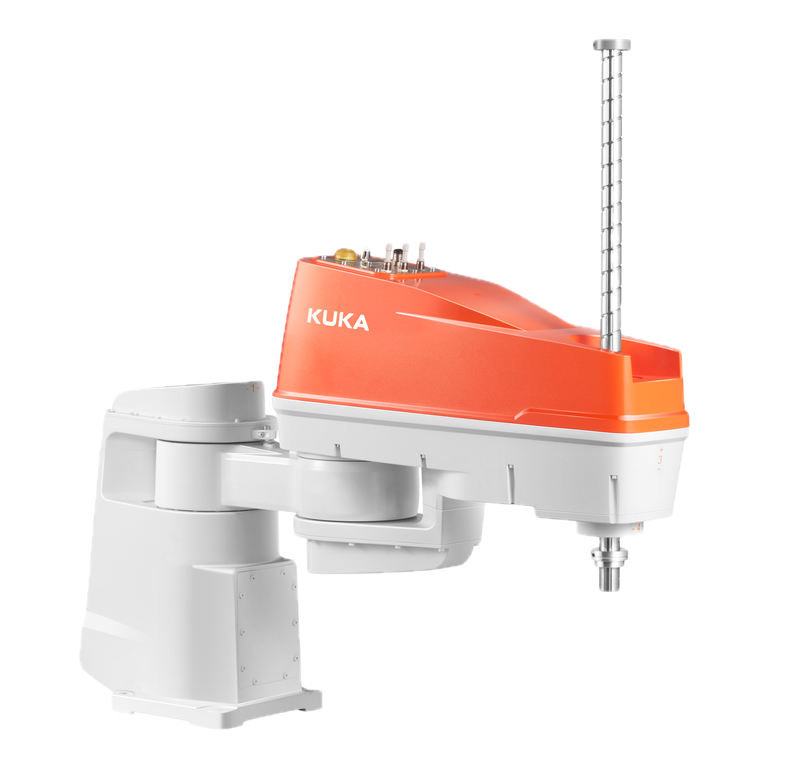

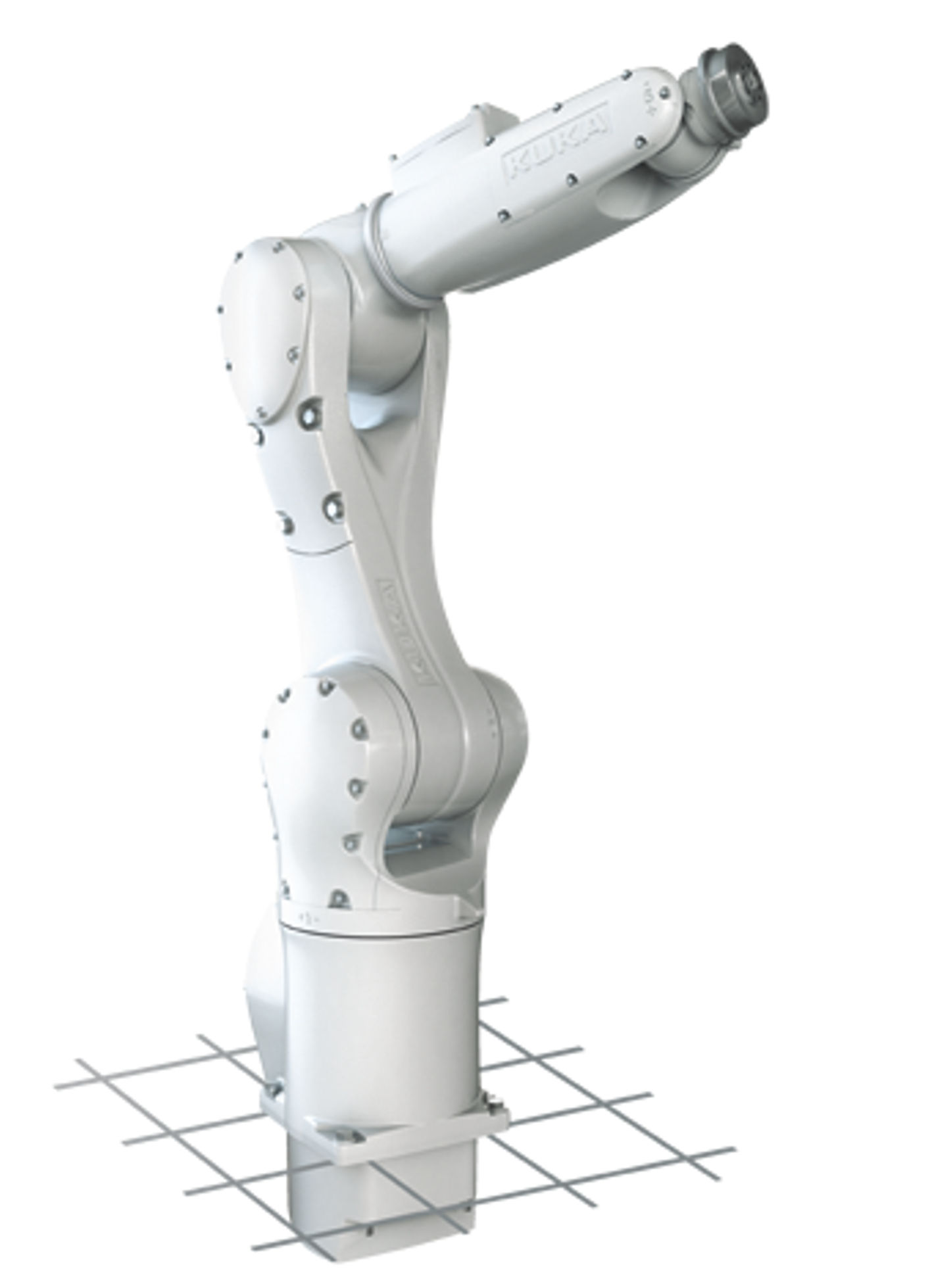

Robotic Assembly Solutions

Automation of classical mass production (assembly) allows you to double labor productivity, as well as reduce production time and costs by 50% or more.High-speed assembly solutions reduce the number of manufacturing defects, and accidents at work.

By implementing individual automation from Robotec, you will be able to respond immediately to changes in demand, freely change the assembly sequence of any product, and diversify production cheaply. The introduction time of a new type of product to the market will be significantly reduced.

![[Alt]](/upload/iblock/9fe/zmh7oqb4j1g0ejofzppa0qb9wr1nqyfy.png)

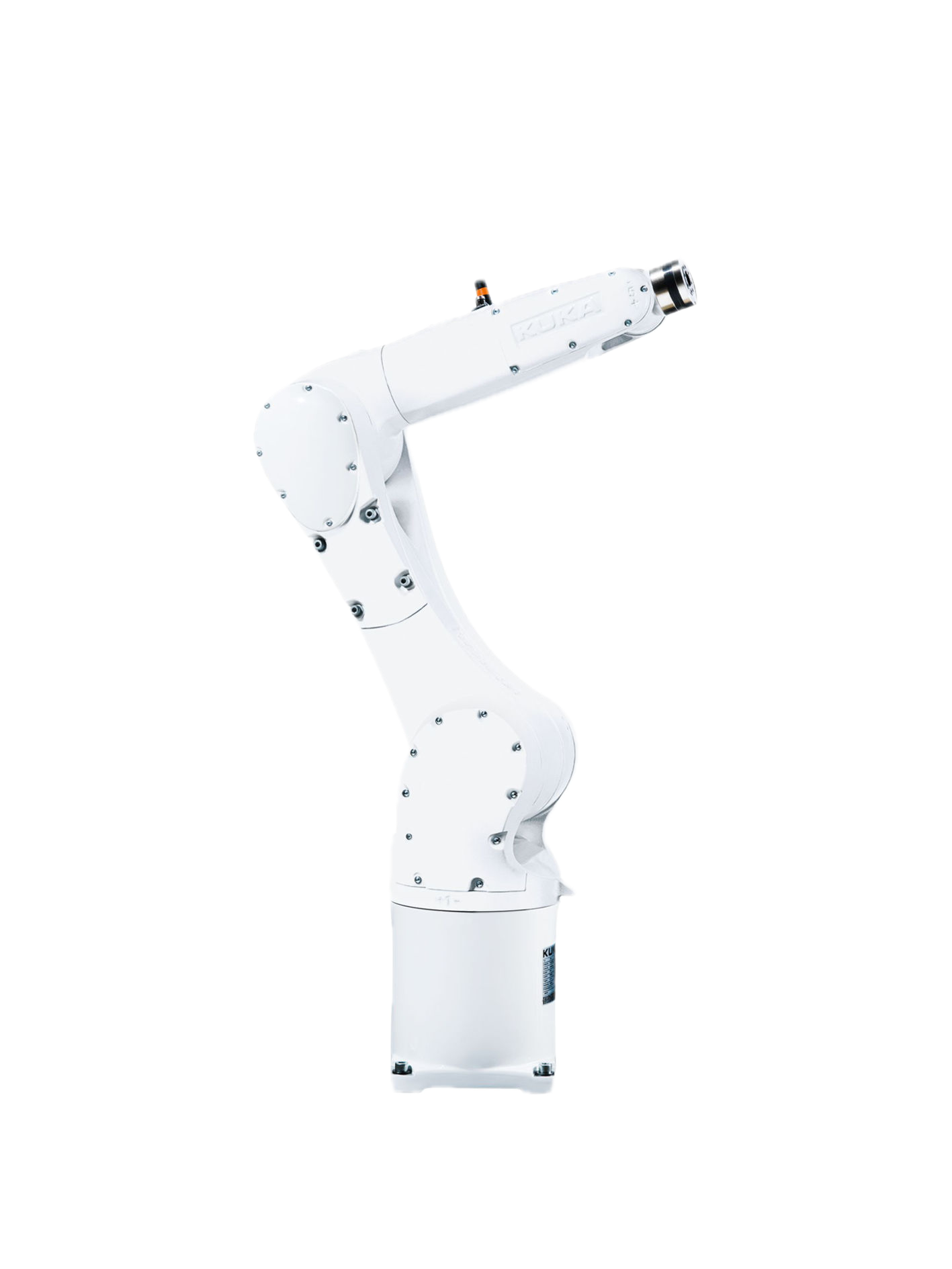

Industries

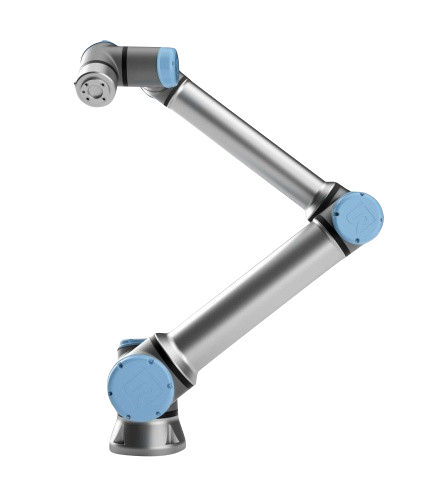

What advantages can be obtained from assembly automation.

a radical increase in productivity efficiency

and safety of production processes;

improving the safety

and quality of working conditions: automated systems take on physically ;

continuity of the assembly process

line operation – up to 24 hours a day;

prolonged economy of labor resources

all assembly operations using automated solutions are performed without human participation (or with minimal participation);

efficient use of production areas;

precise control

of the technical condition of the equipment;

efficient consumption of electricity;

improved quality of products

reduced expenses from fewer defects;

increased production capacity and profits

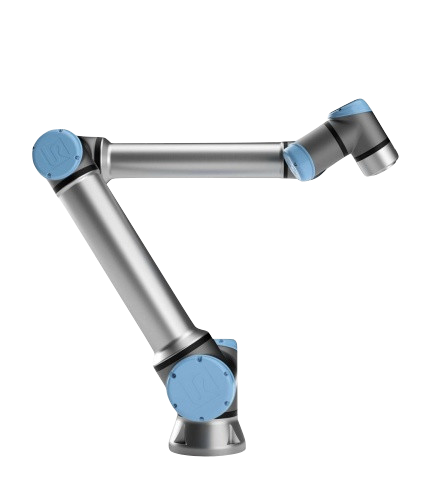

Assembly automation does not have standardized algorithms and requires a creative approach. Our engineers will develop an individual technological solution especially for you.

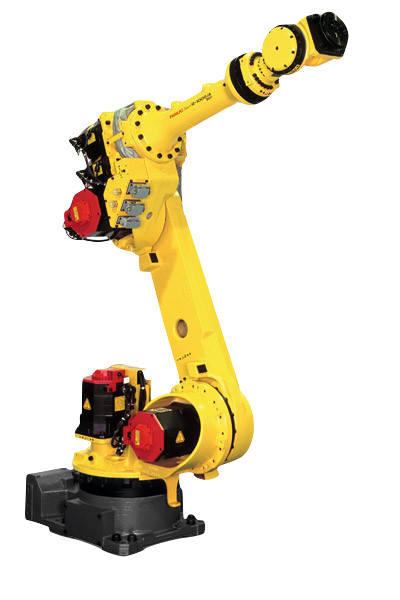

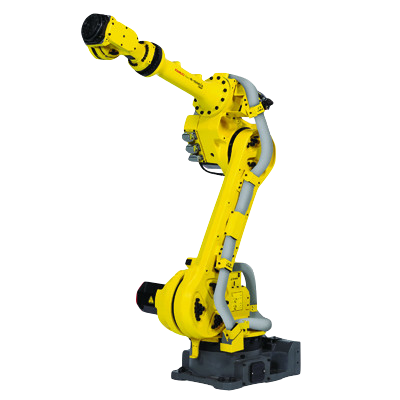

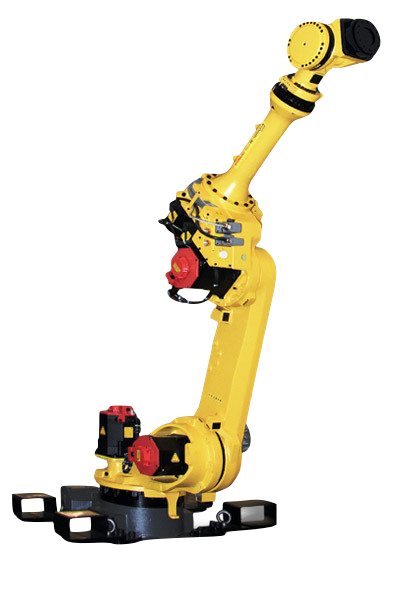

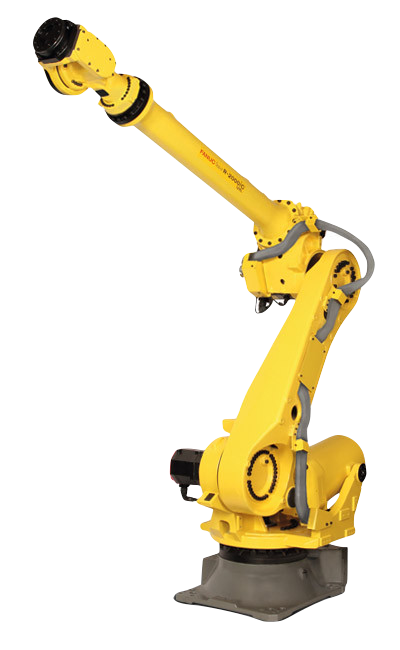

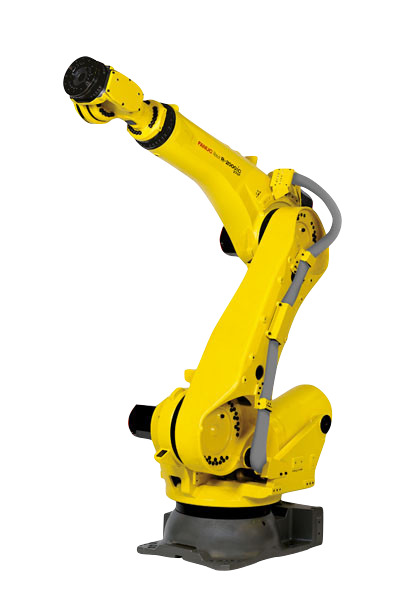

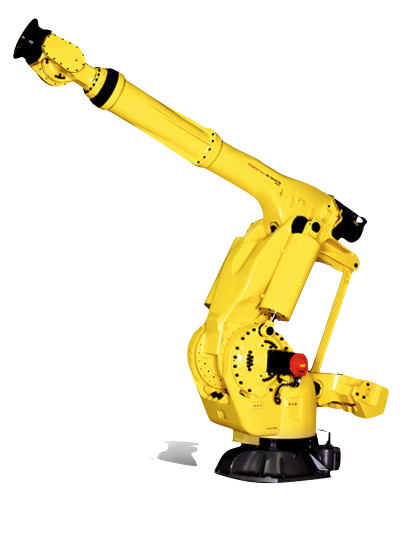

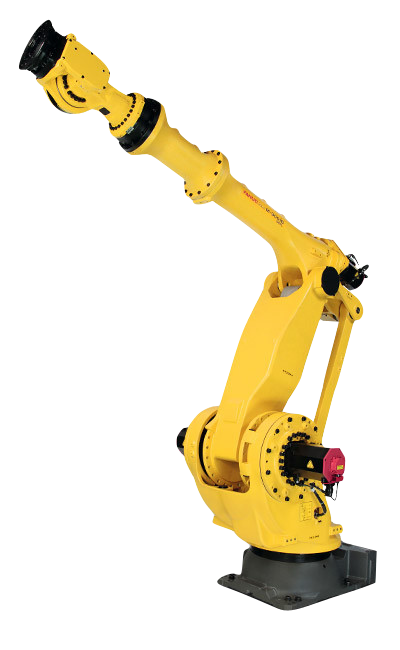

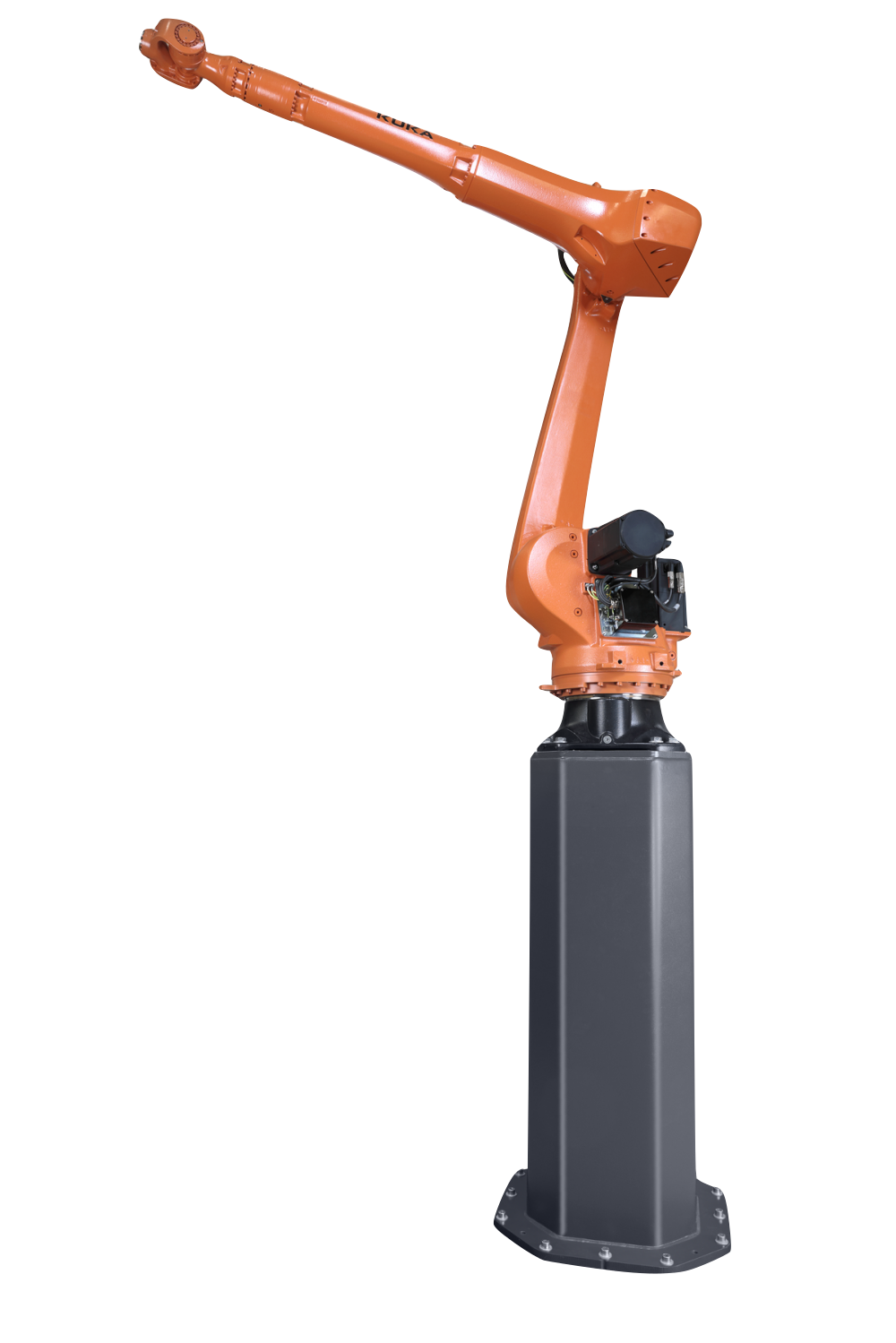

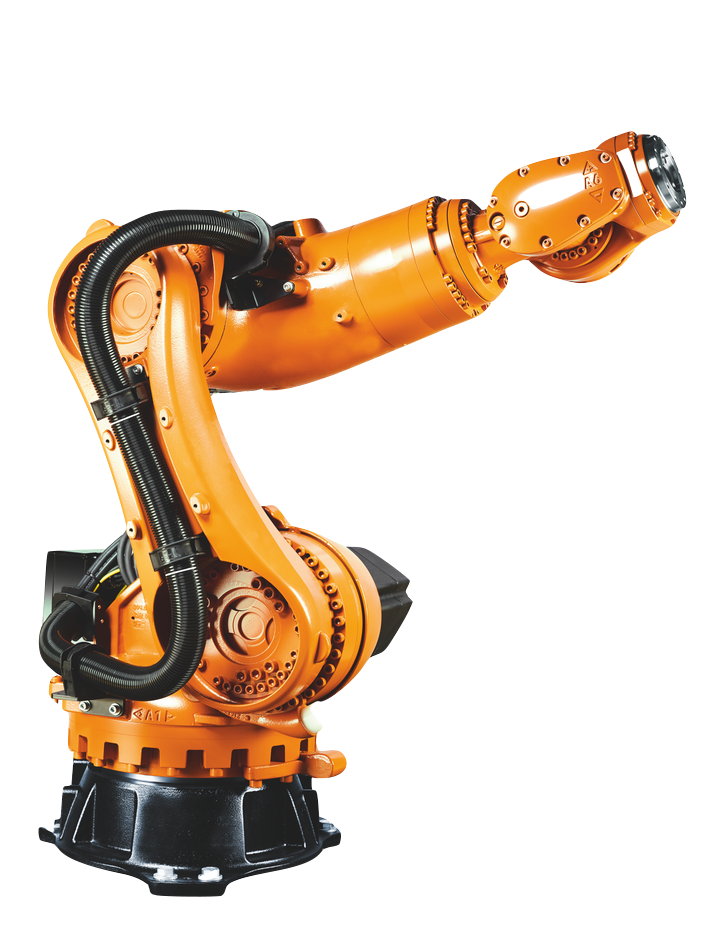

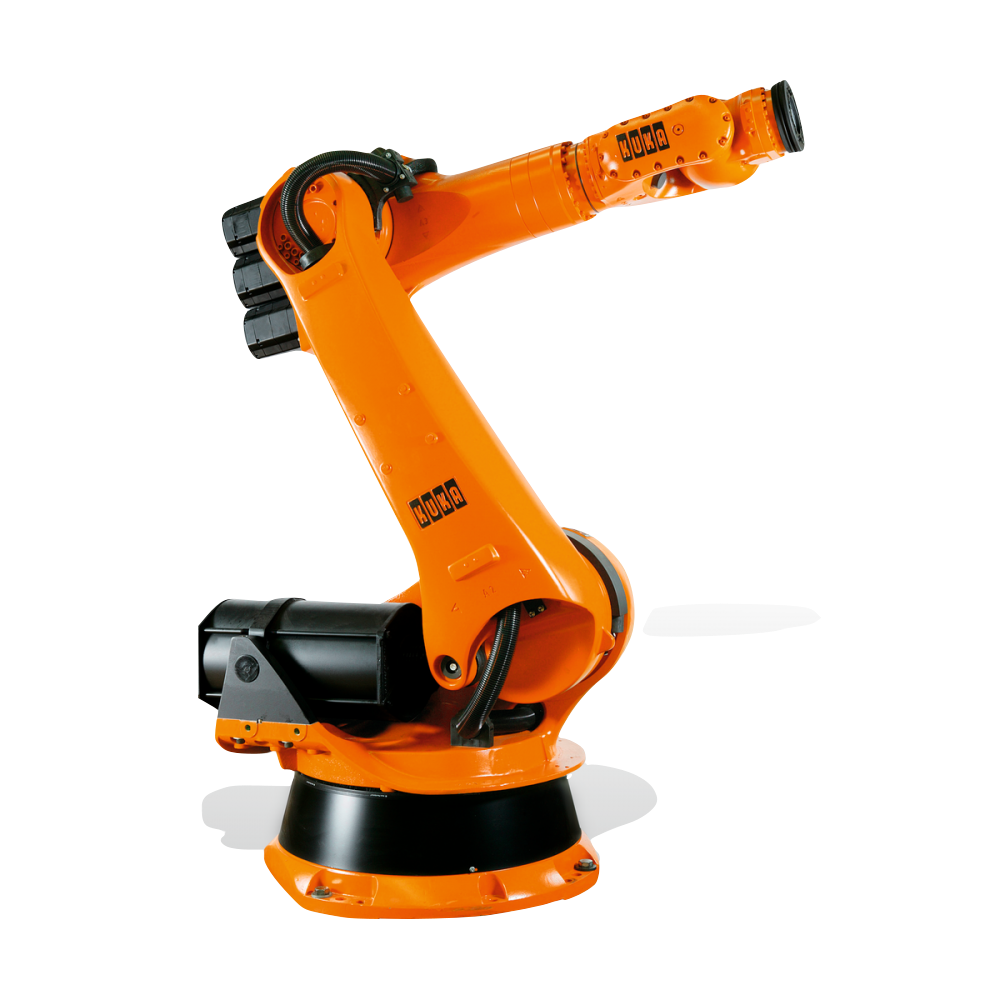

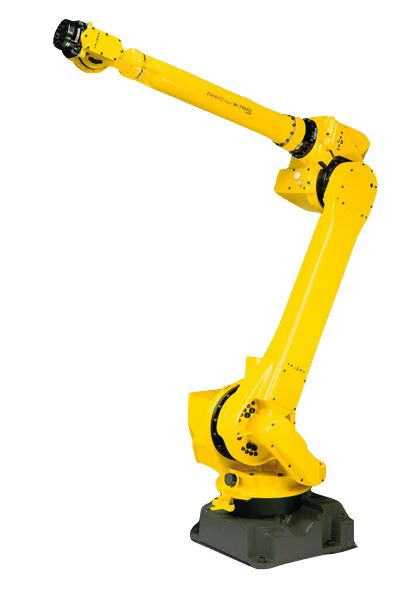

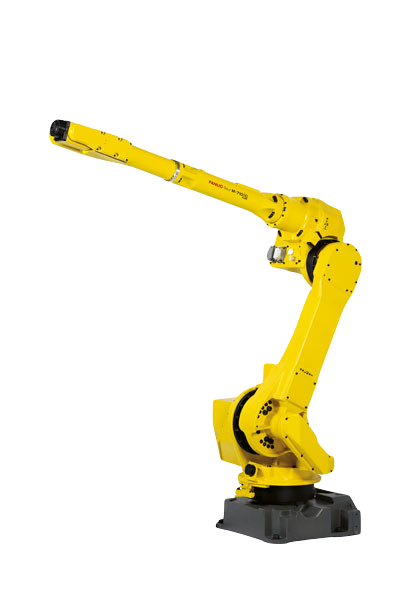

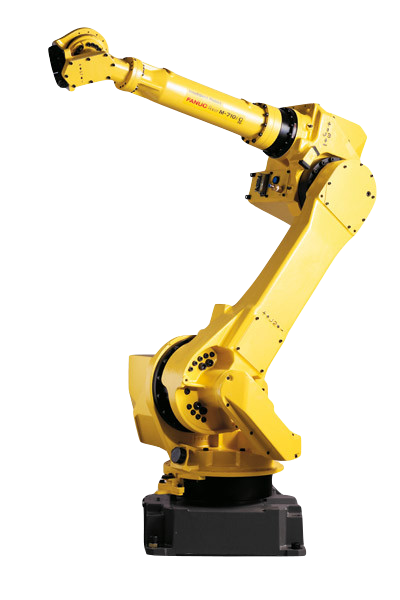

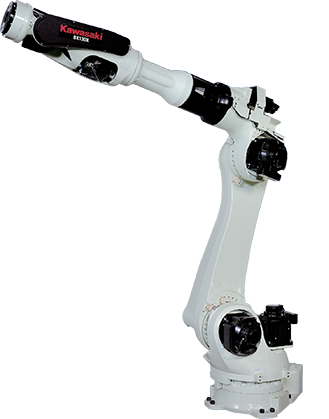

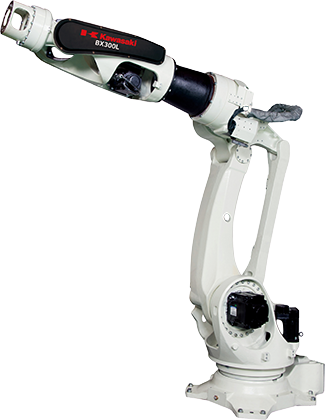

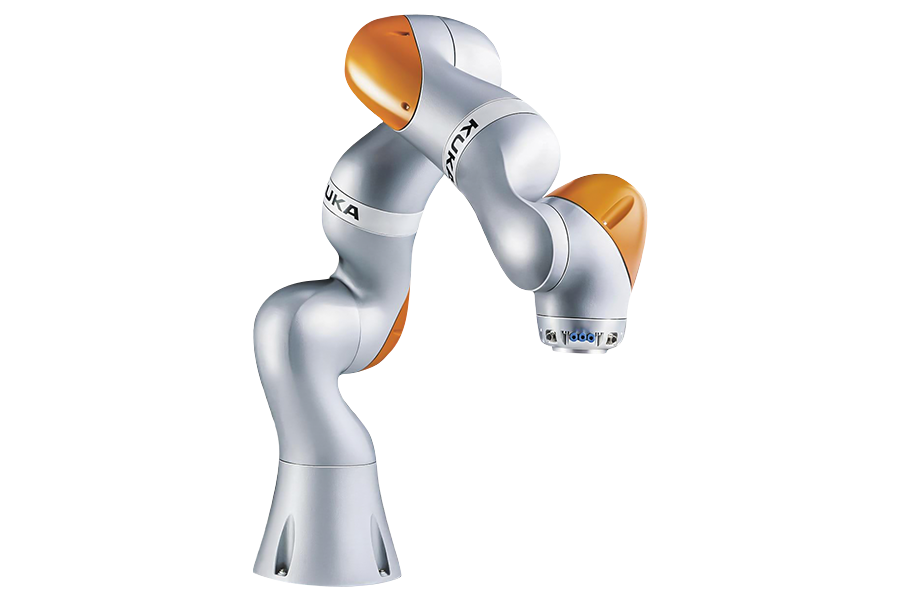

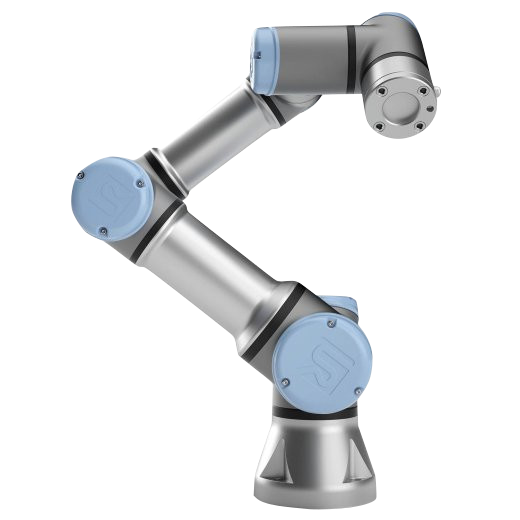

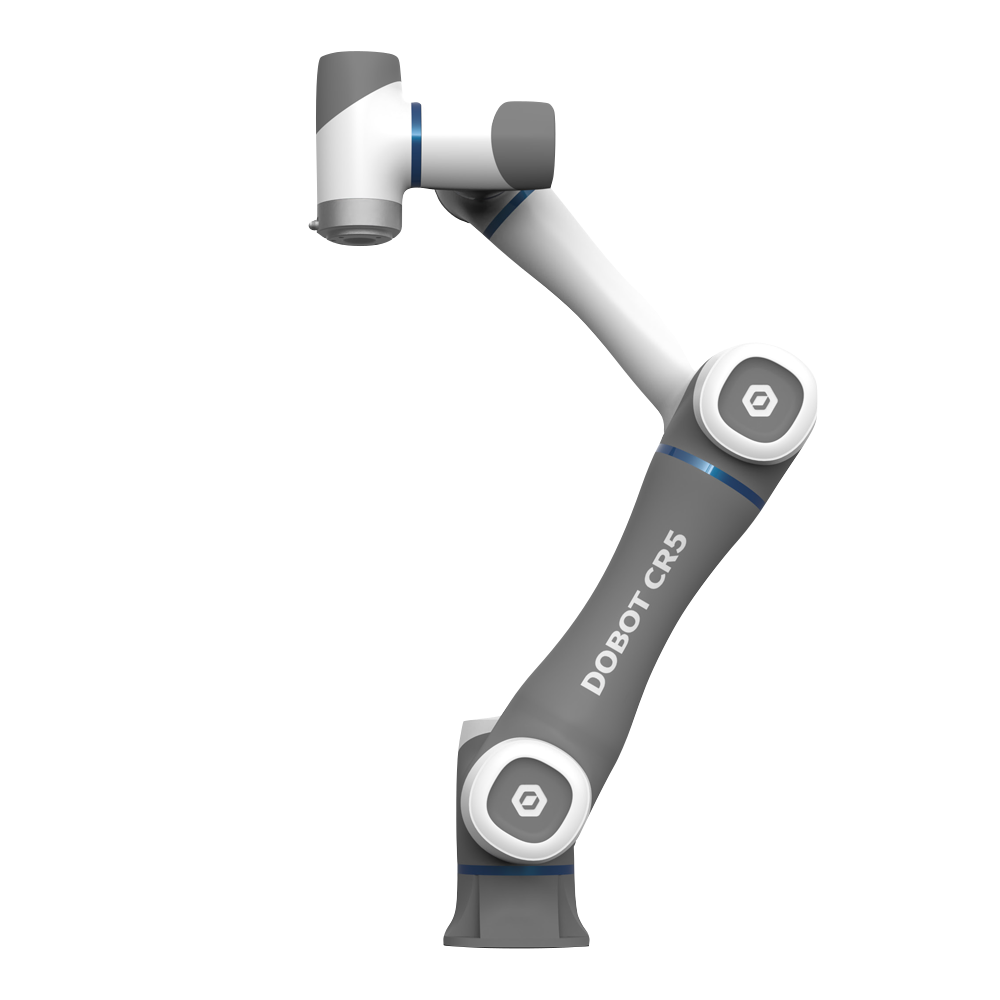

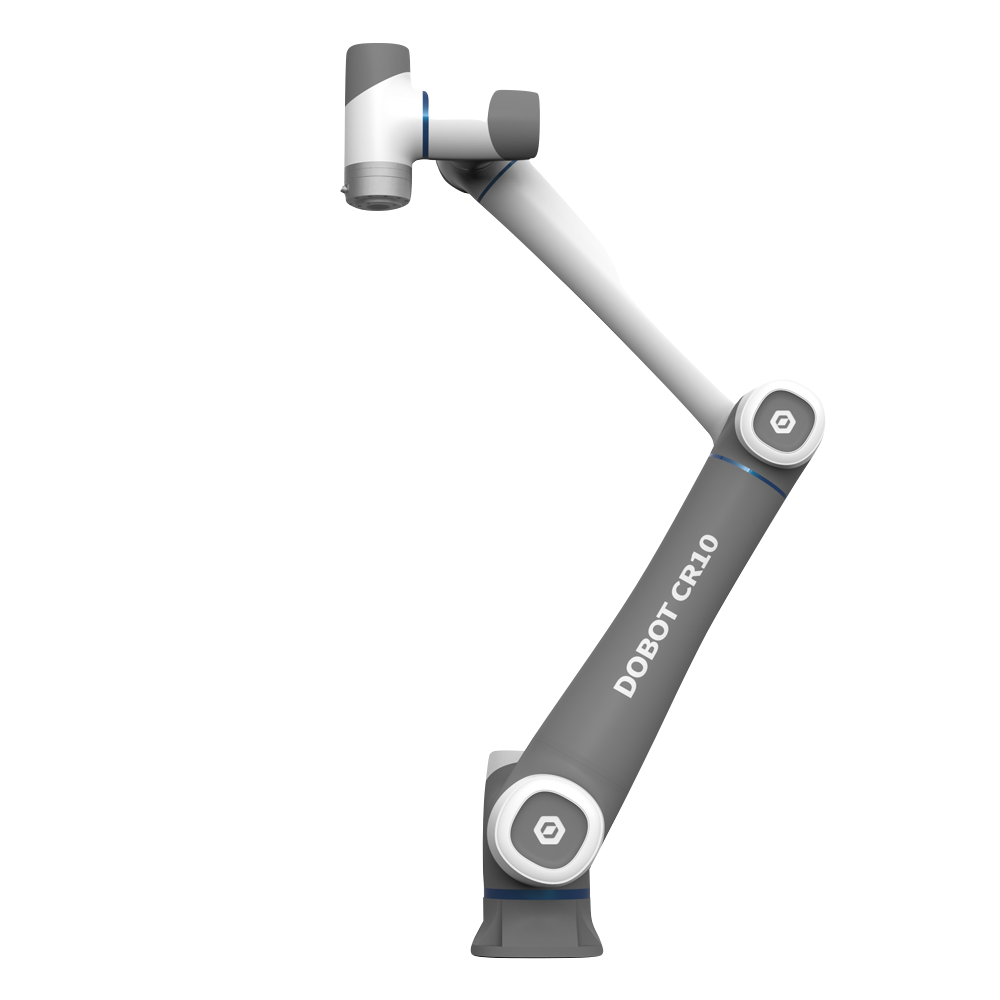

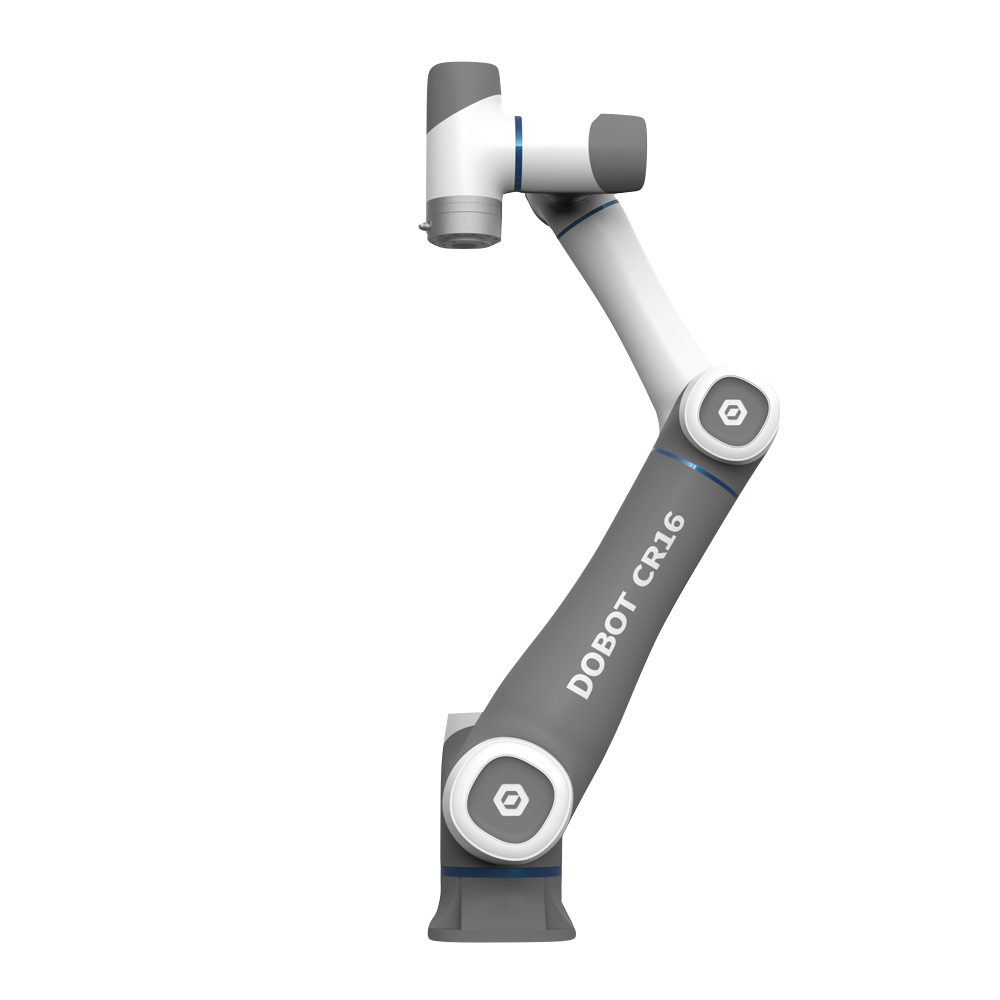

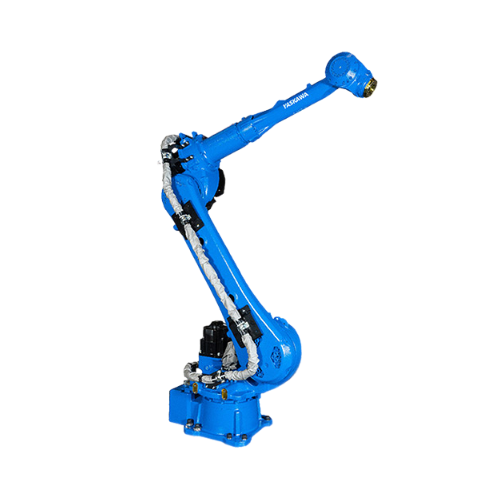

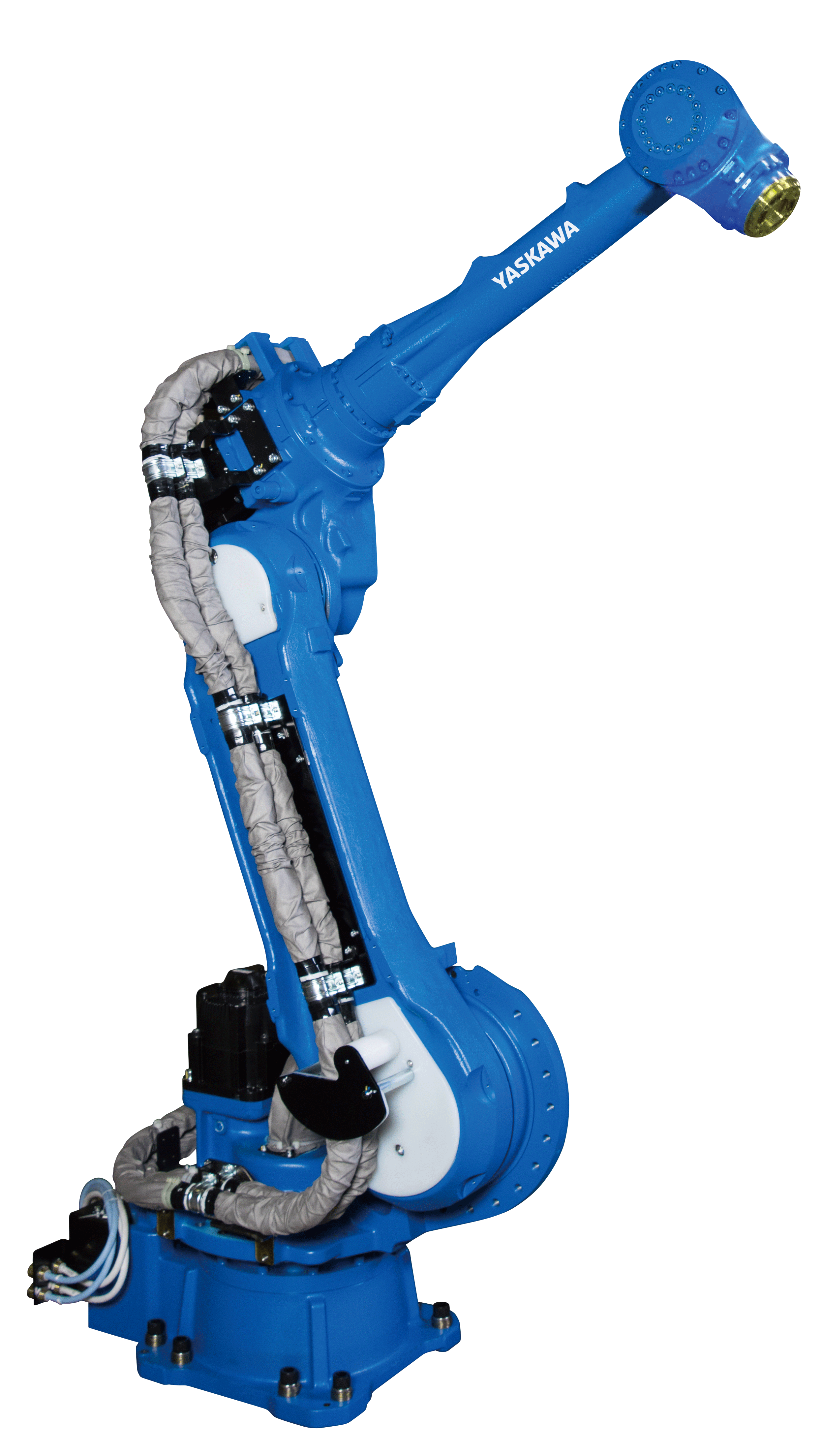

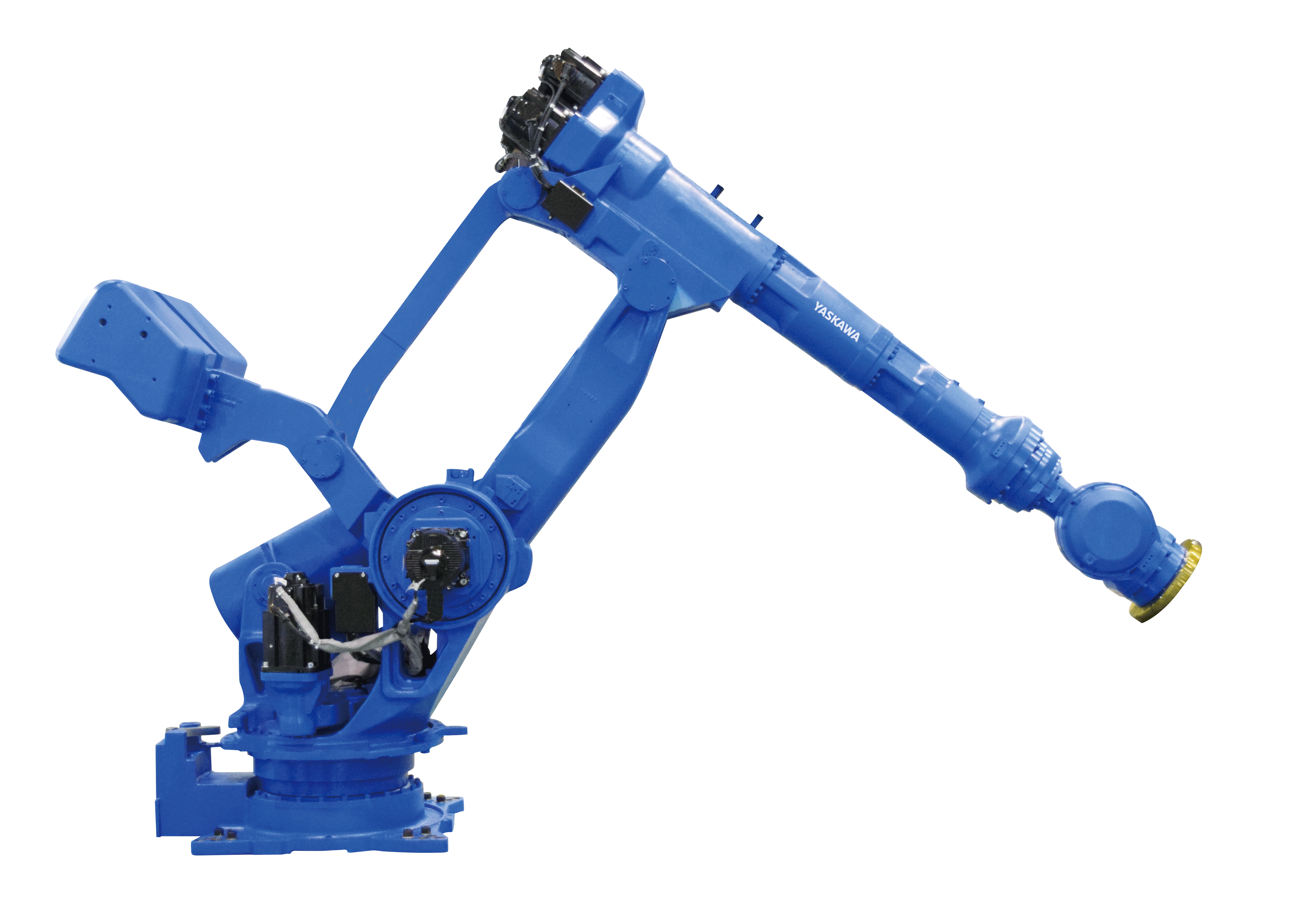

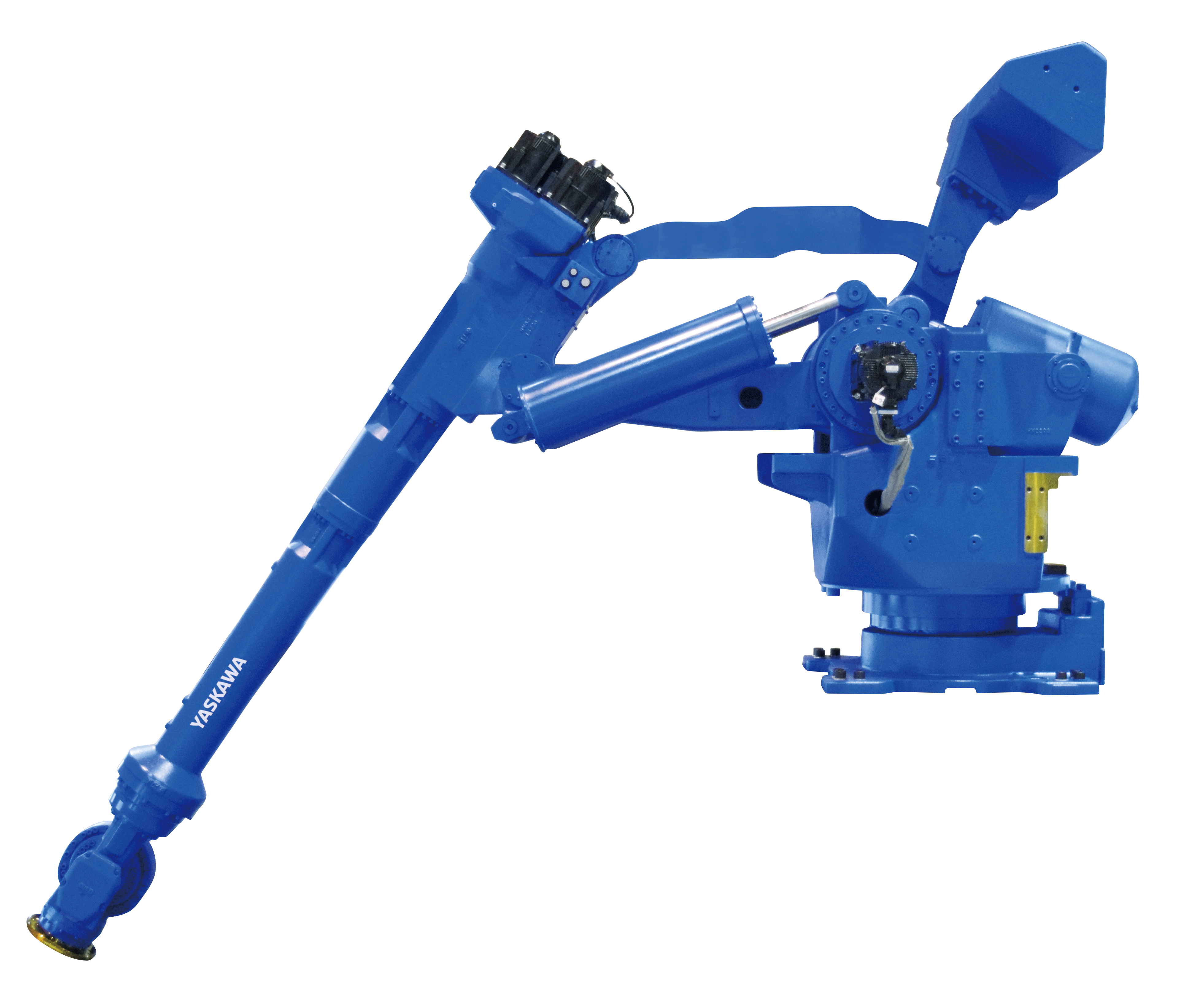

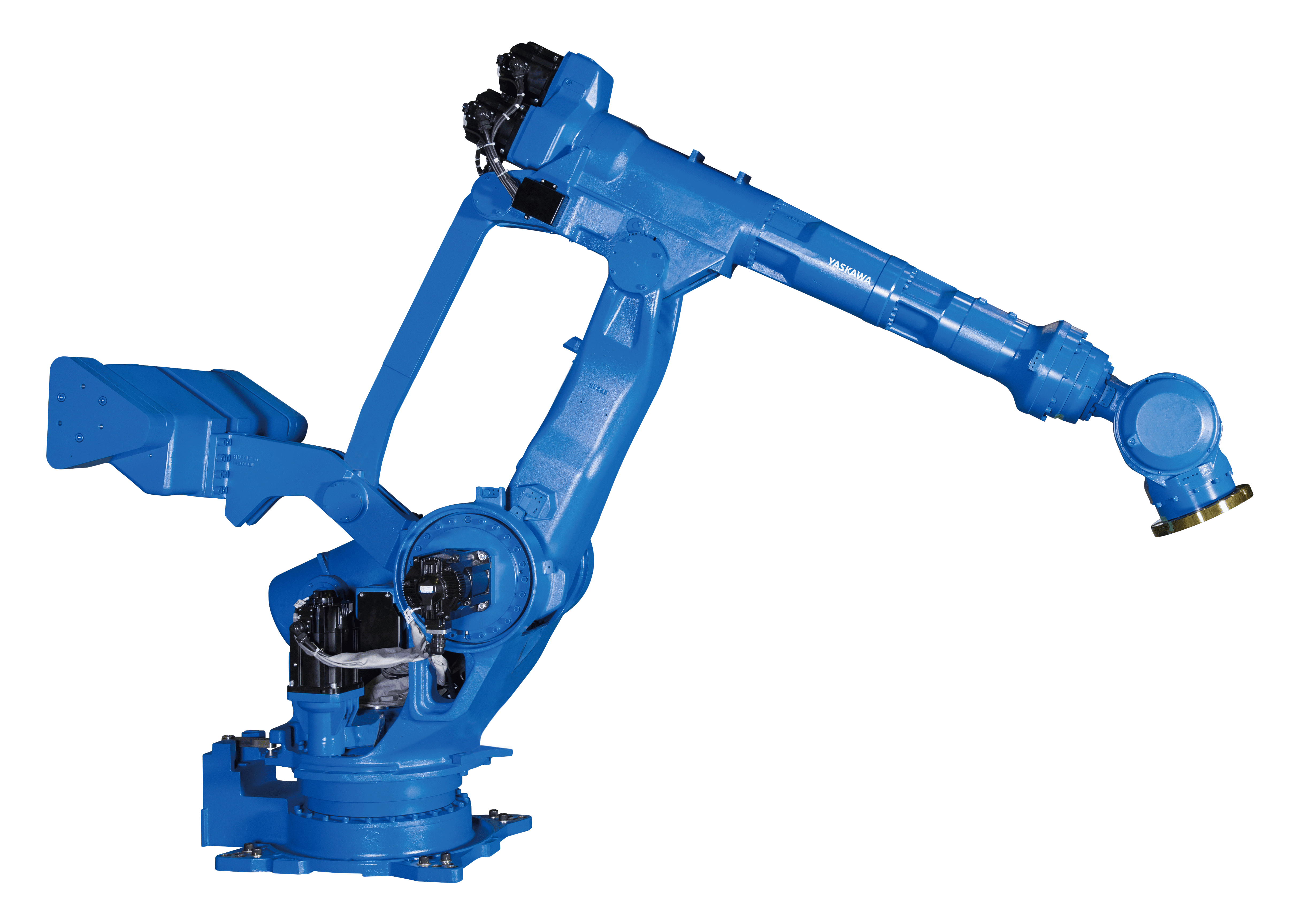

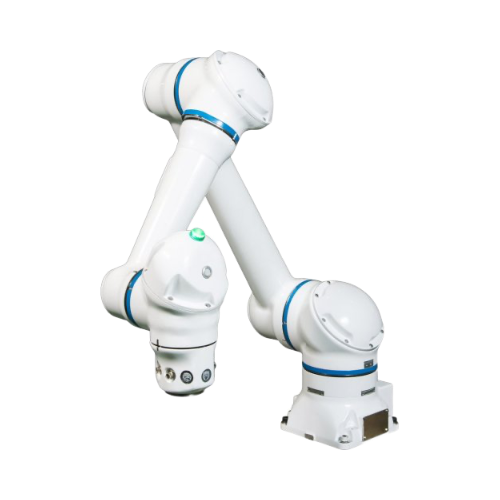

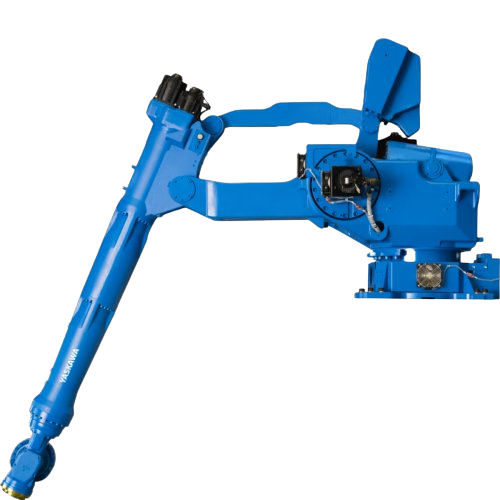

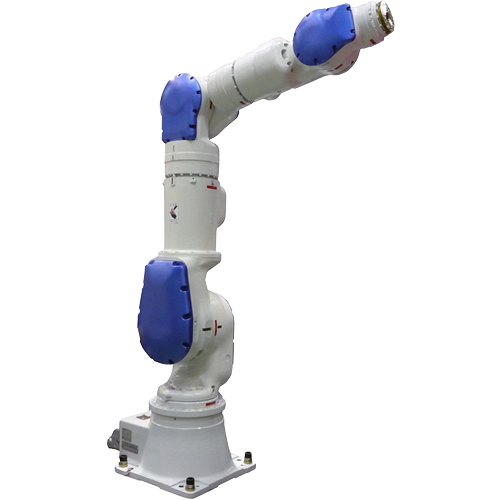

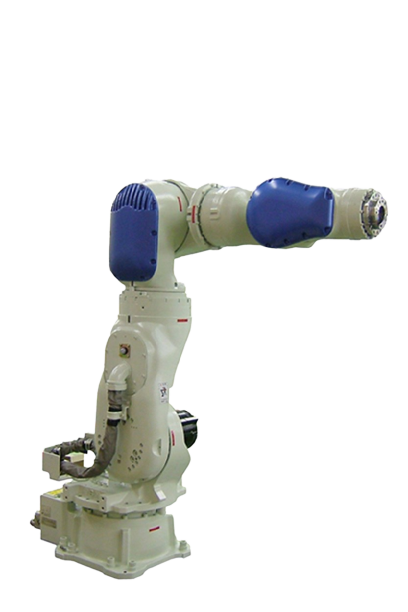

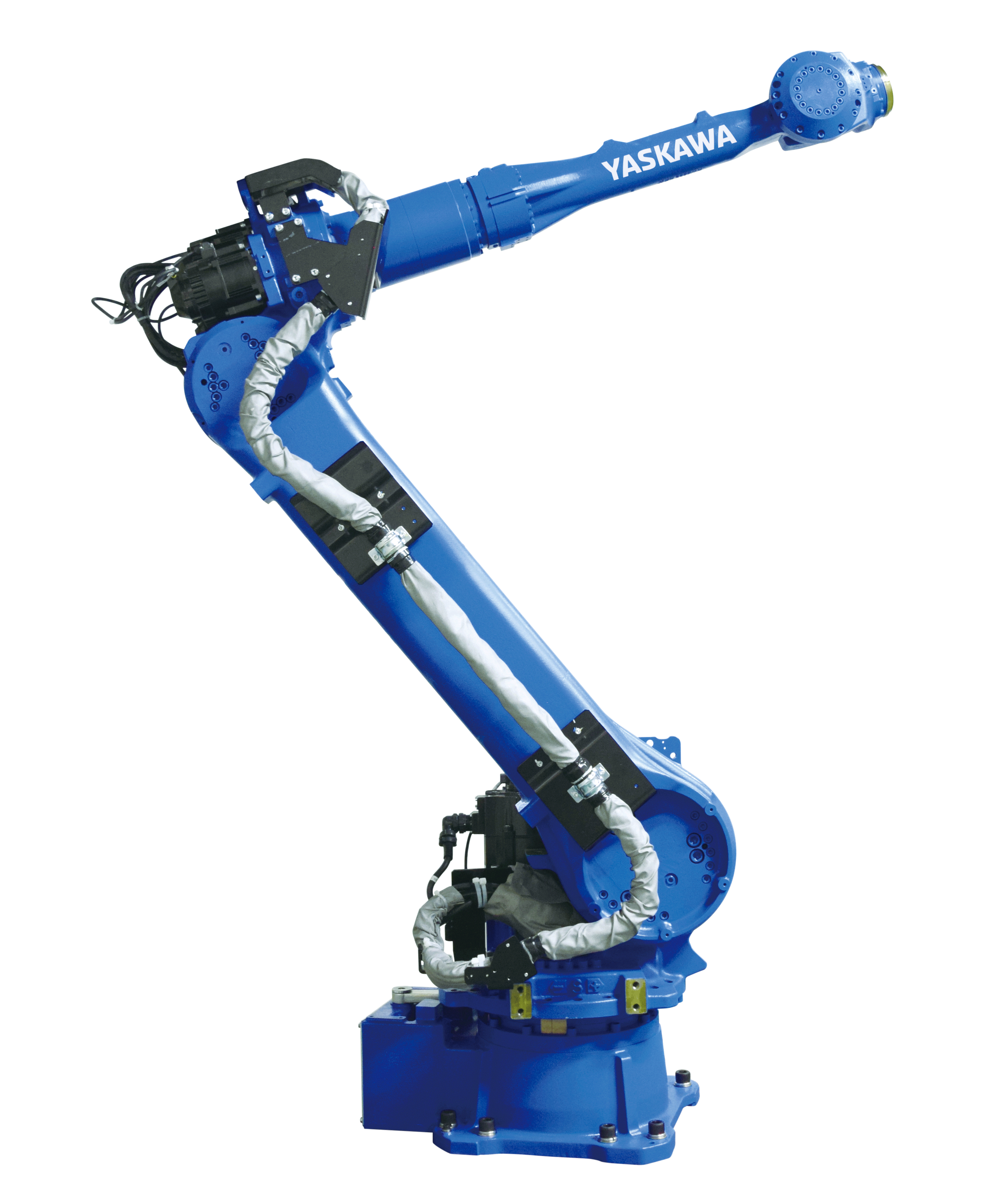

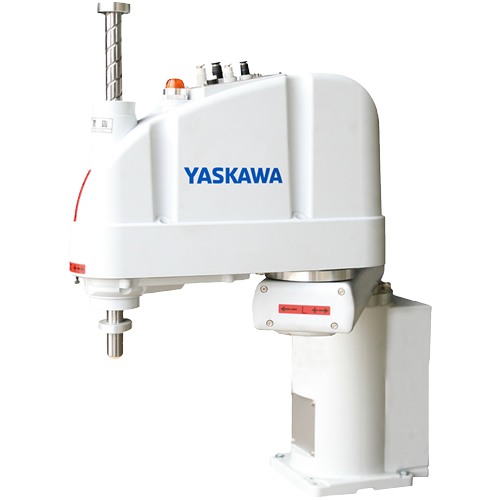

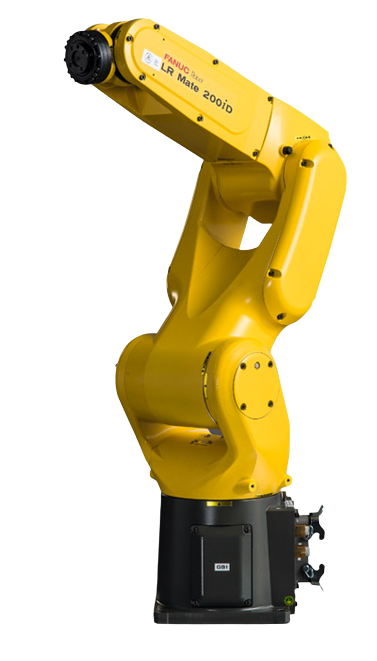

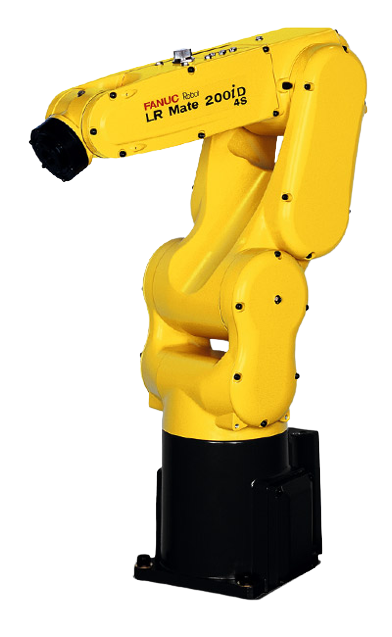

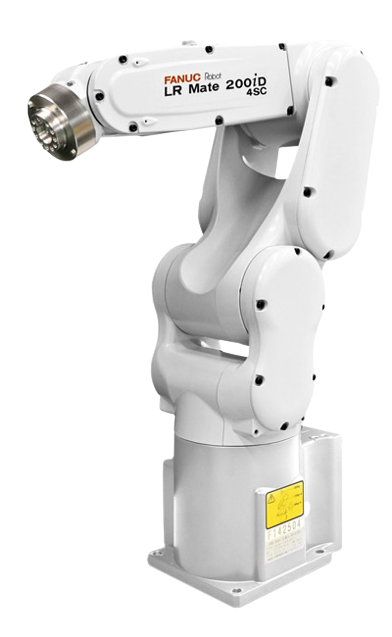

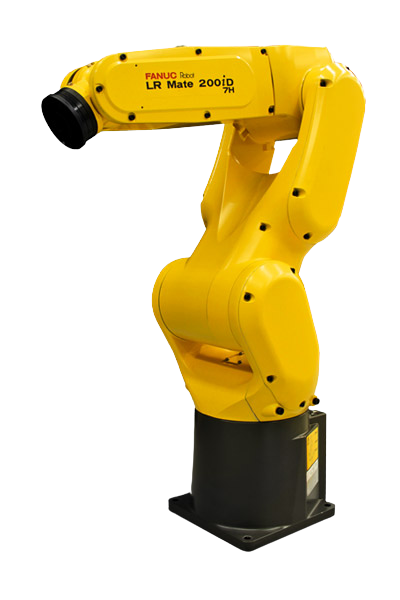

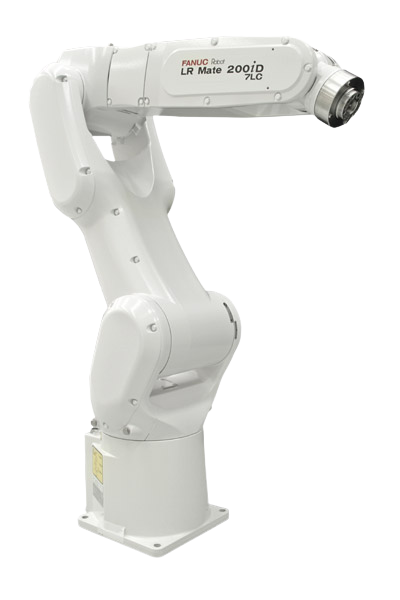

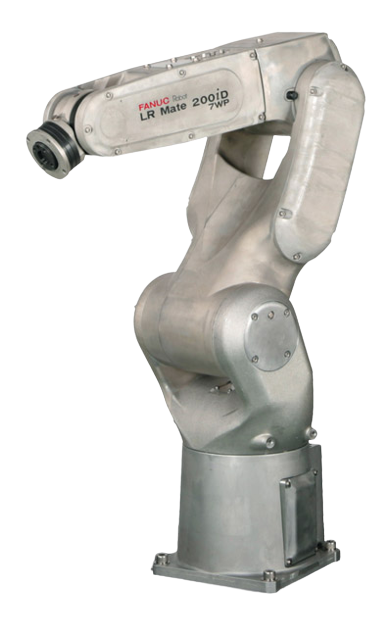

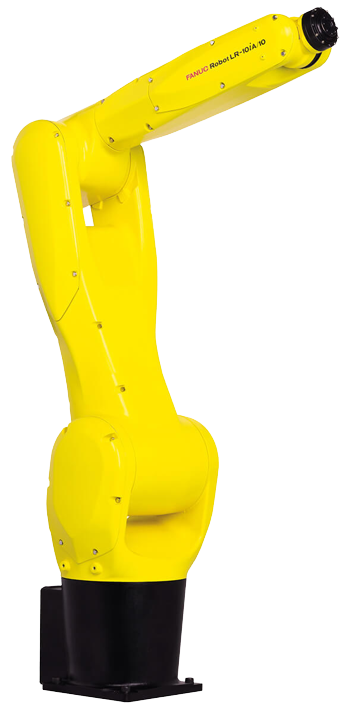

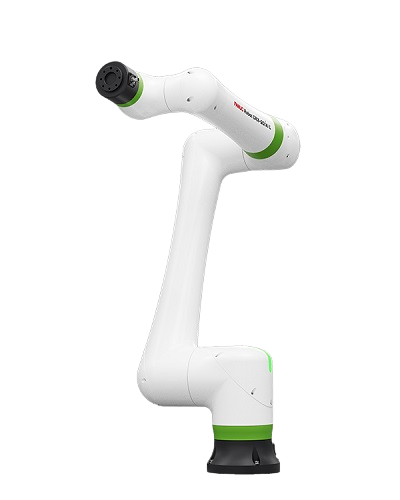

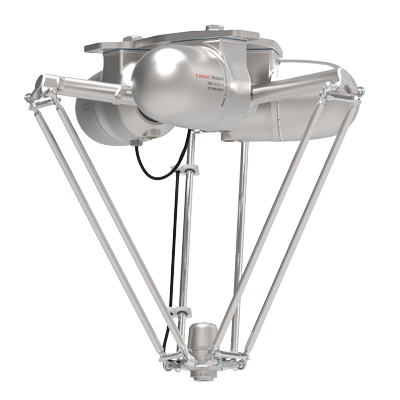

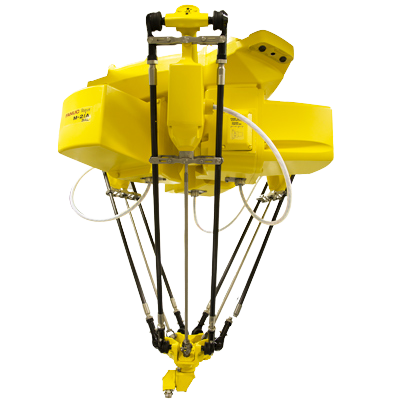

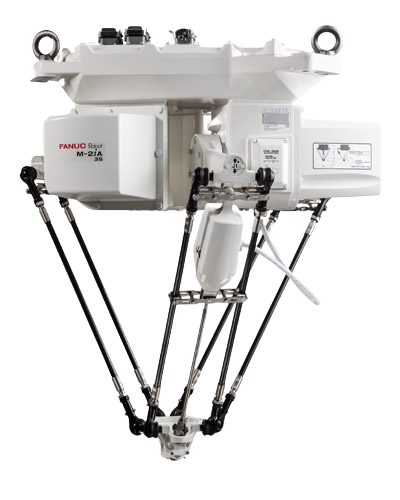

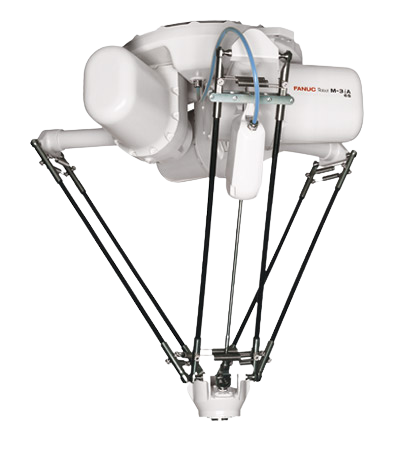

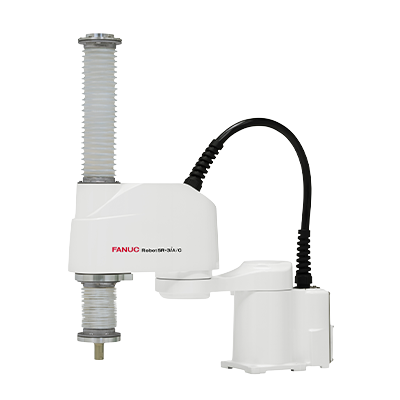

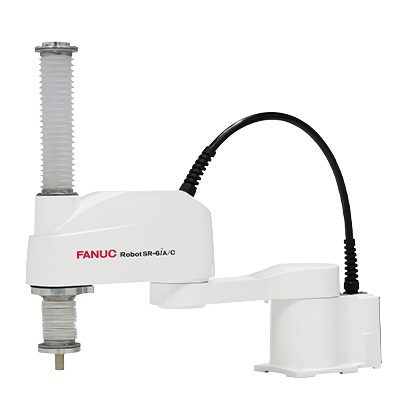

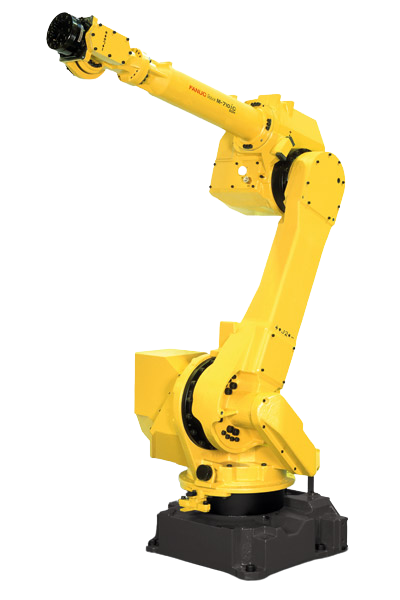

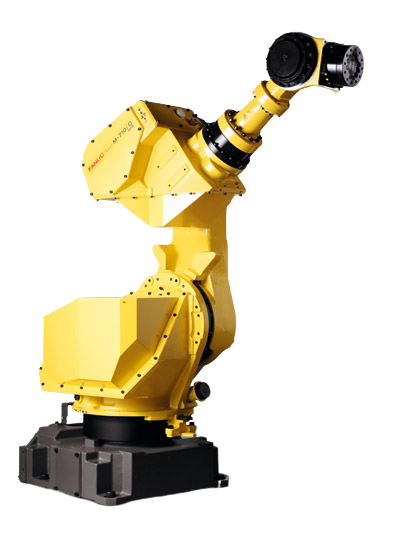

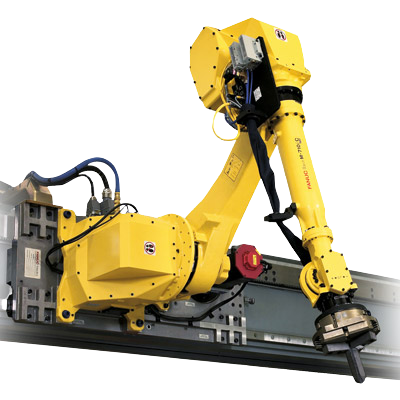

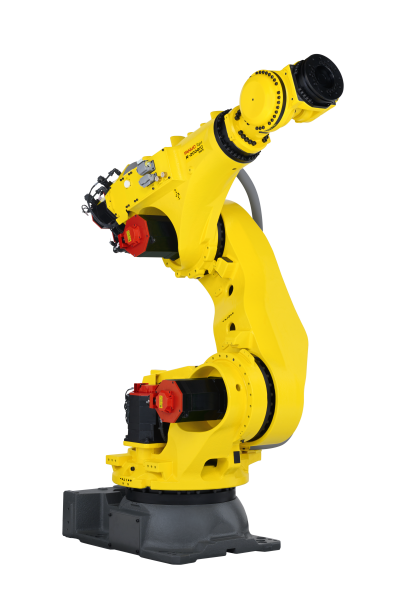

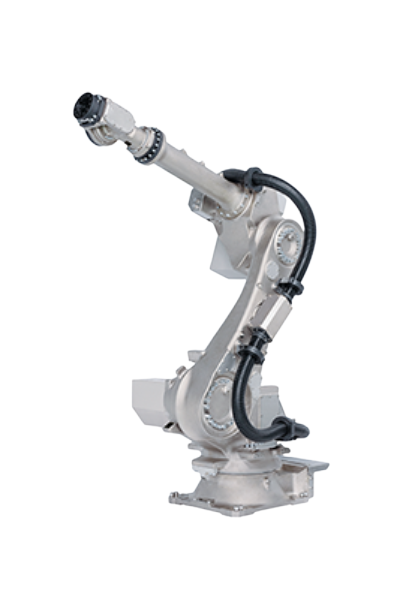

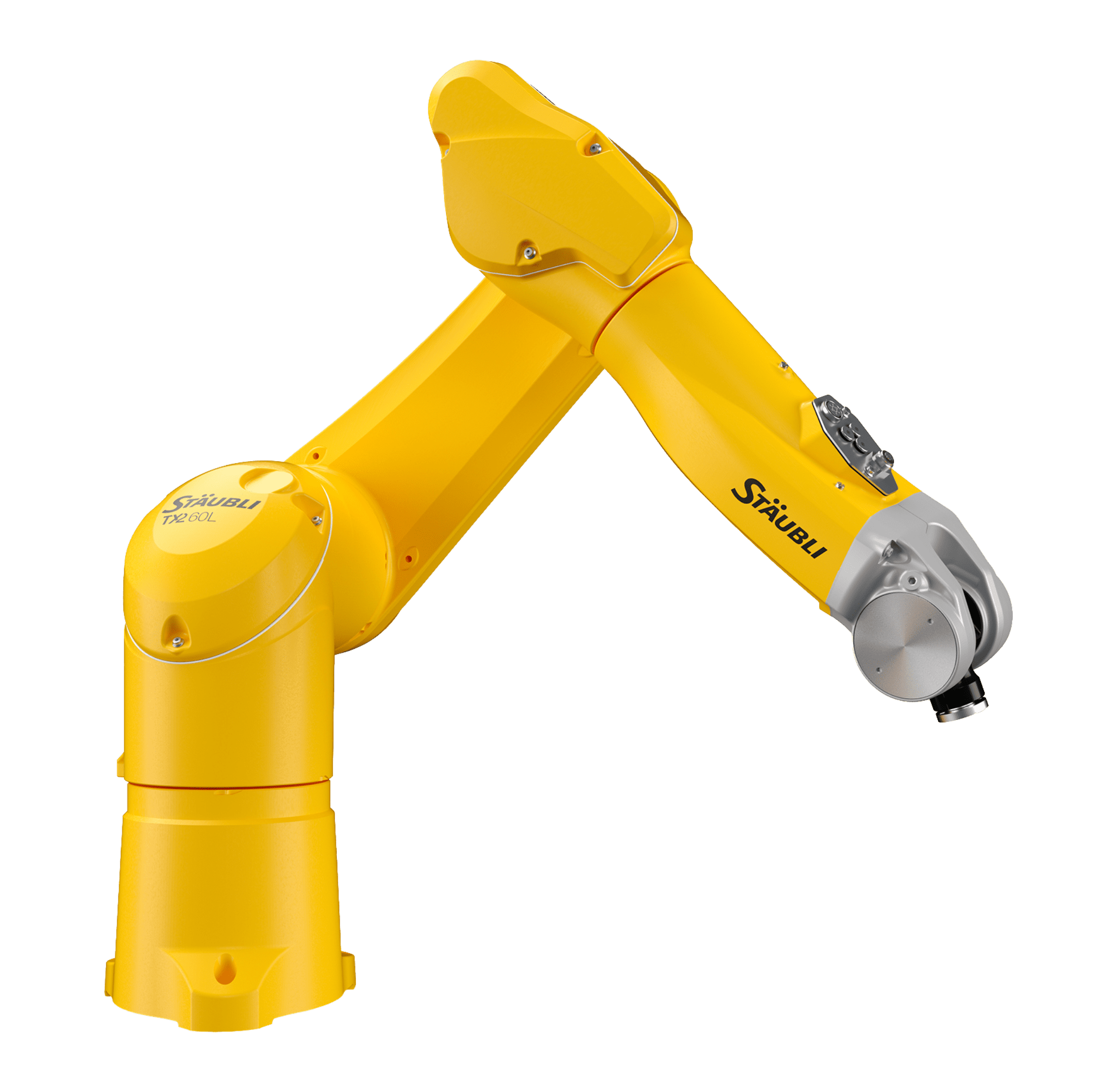

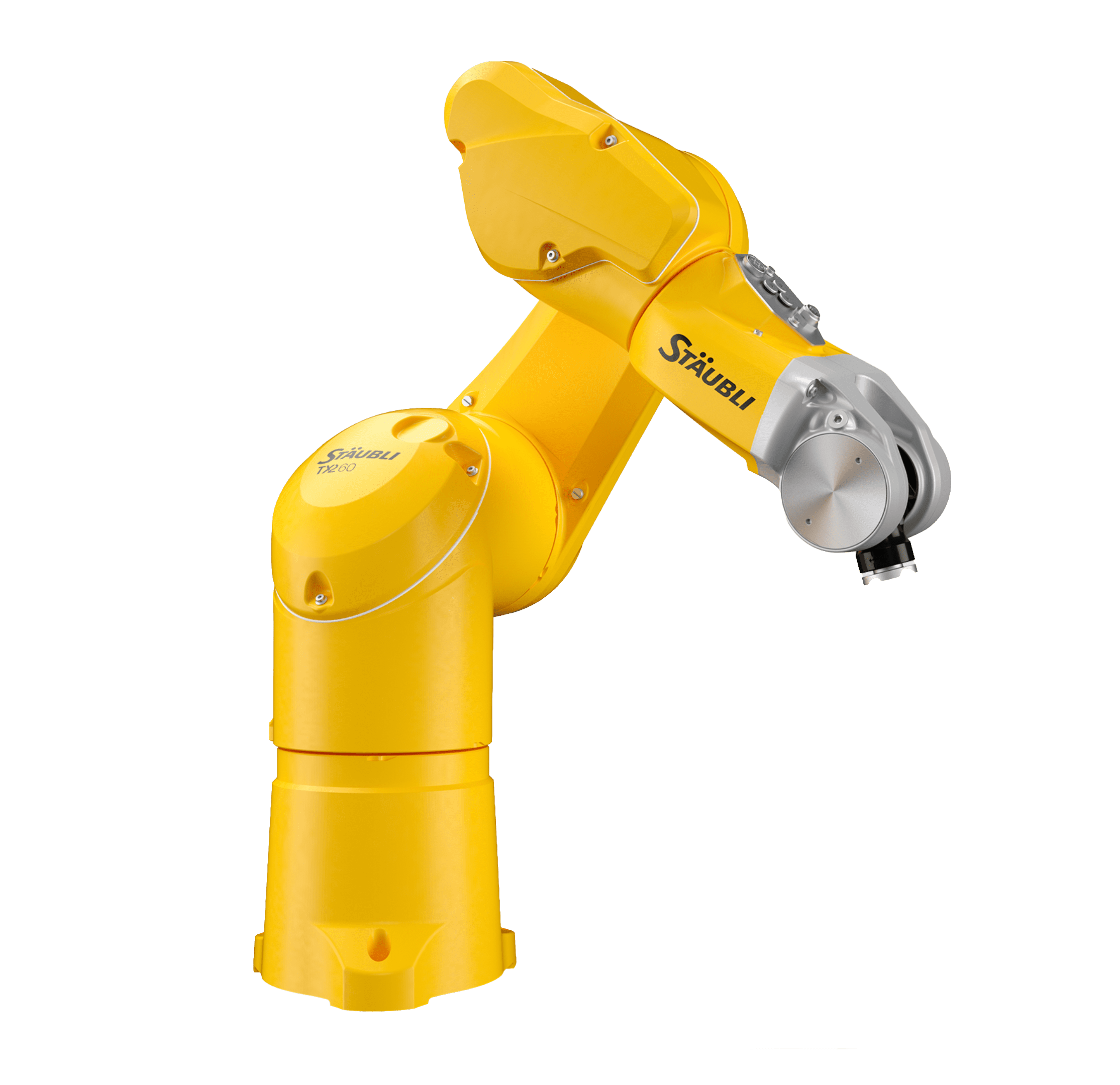

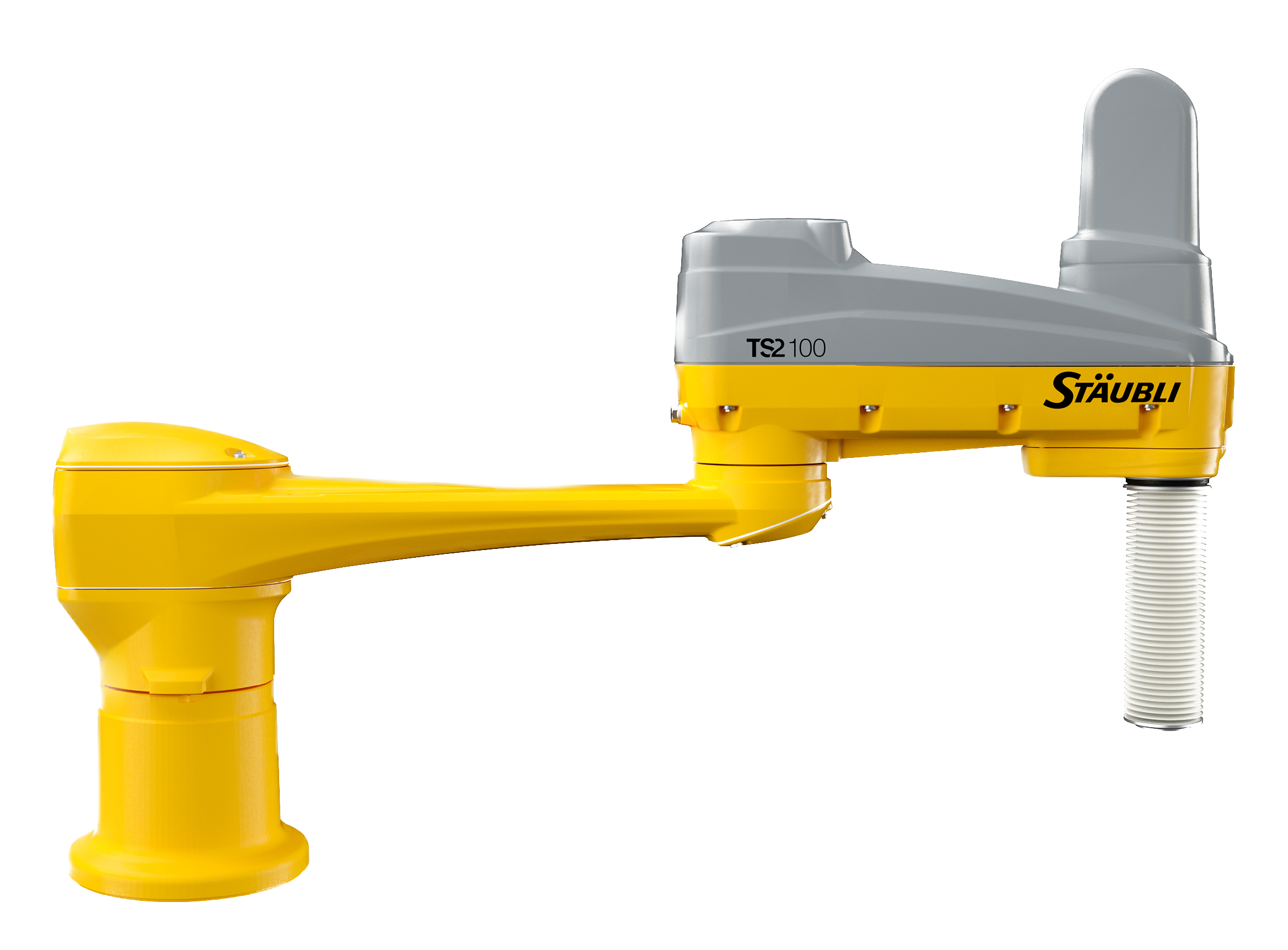

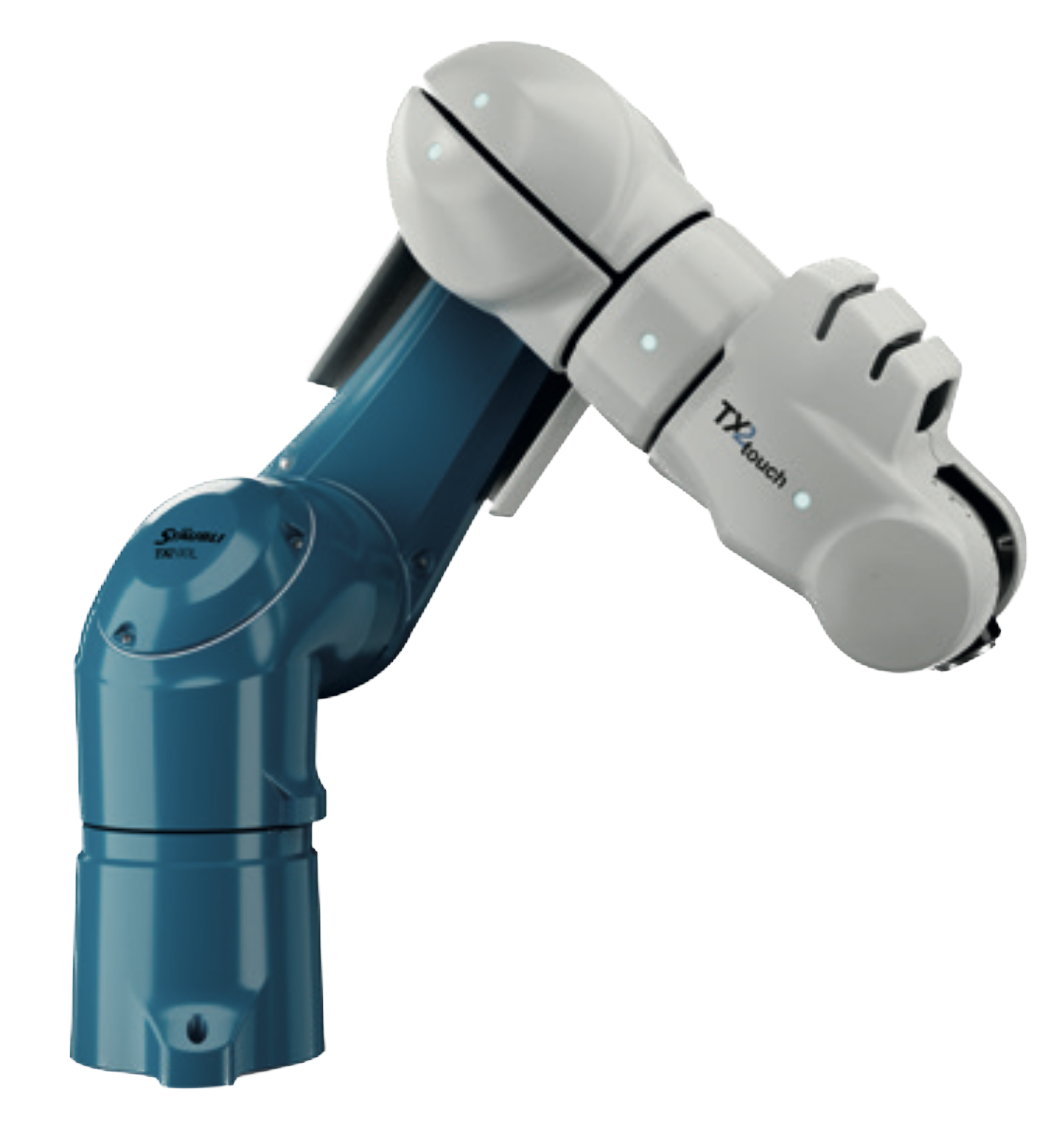

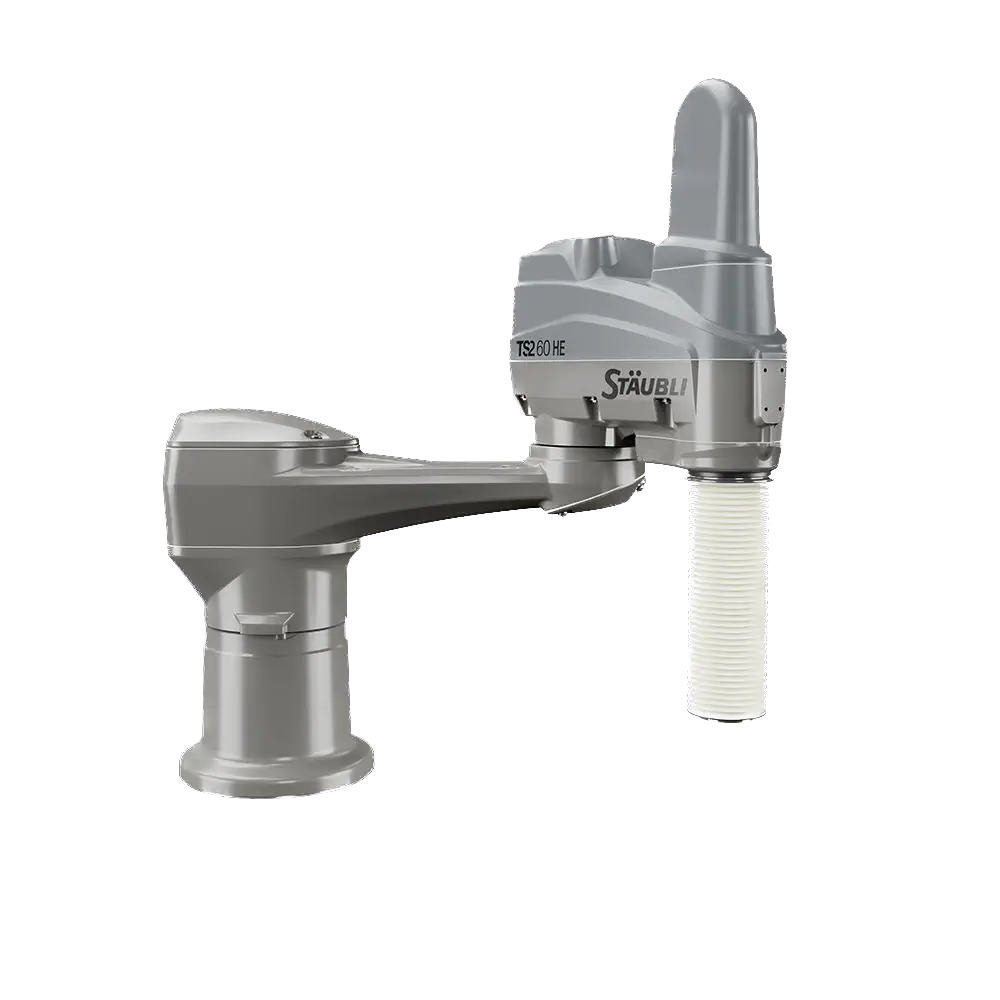

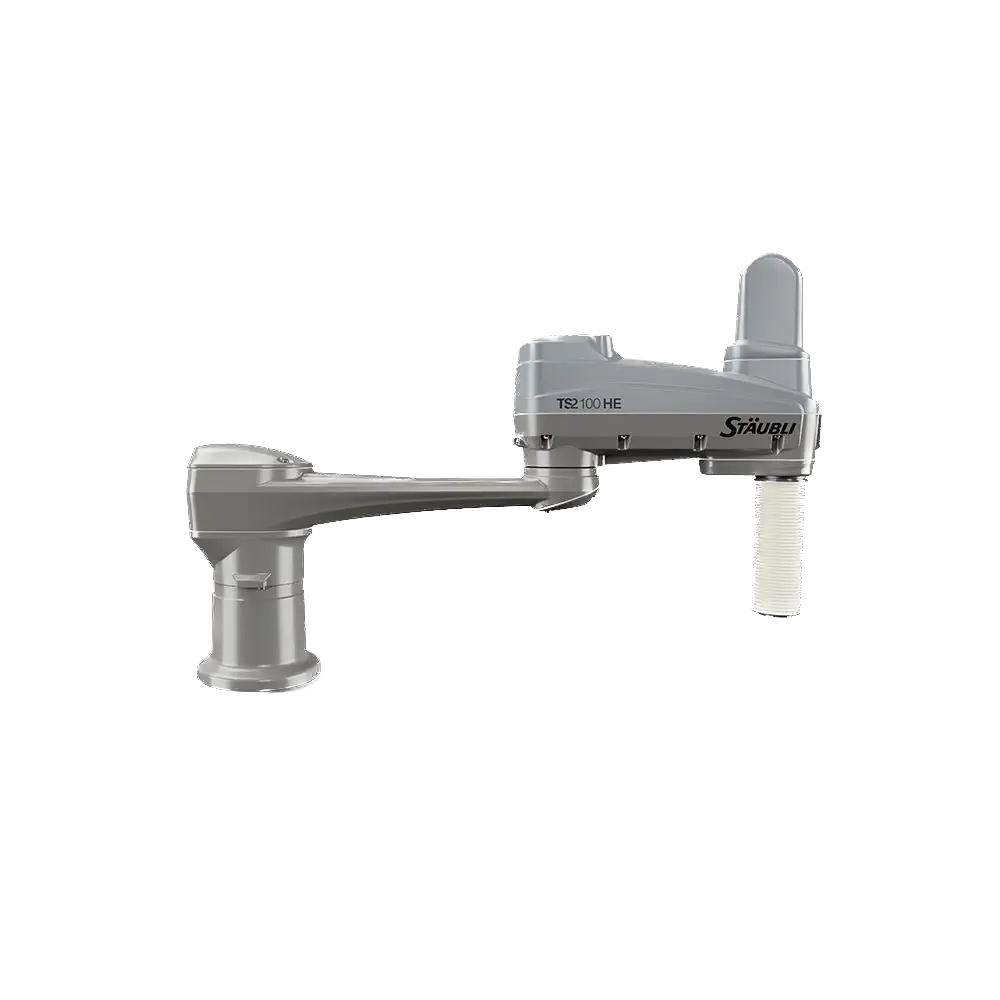

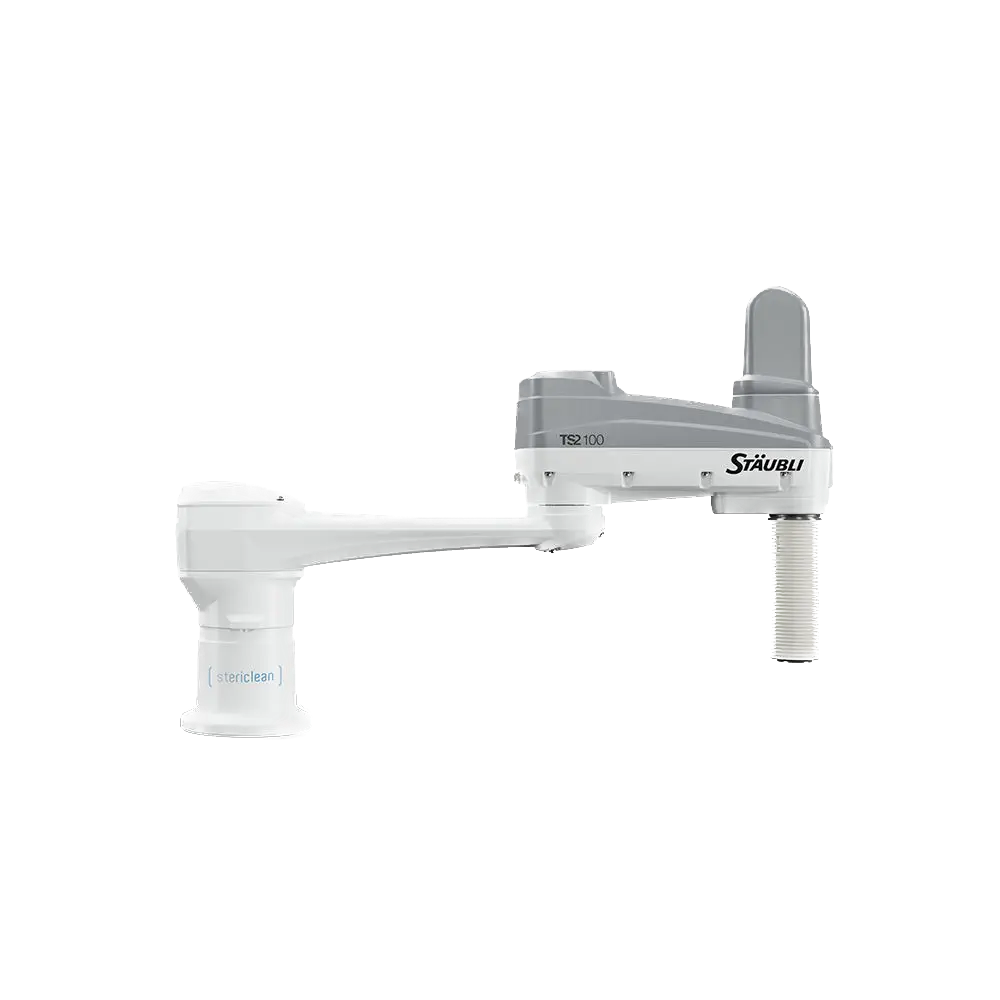

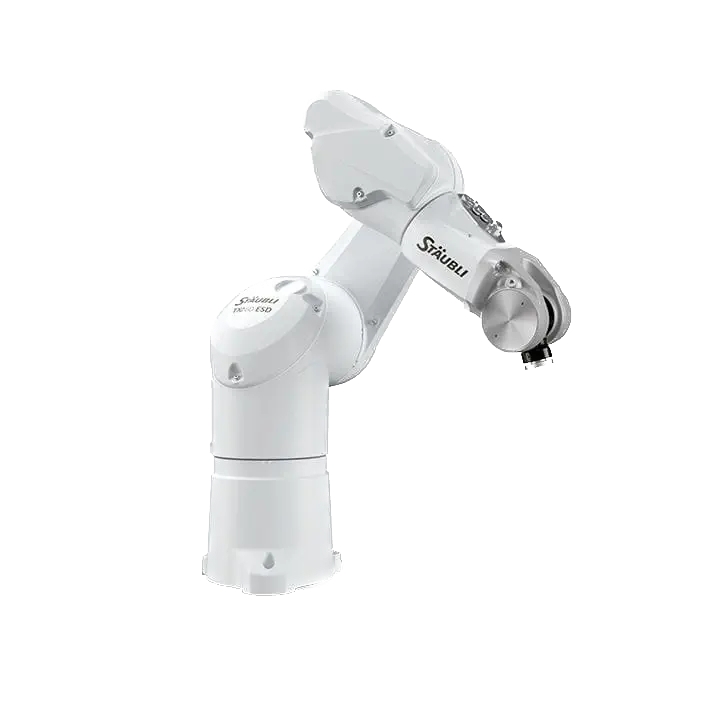

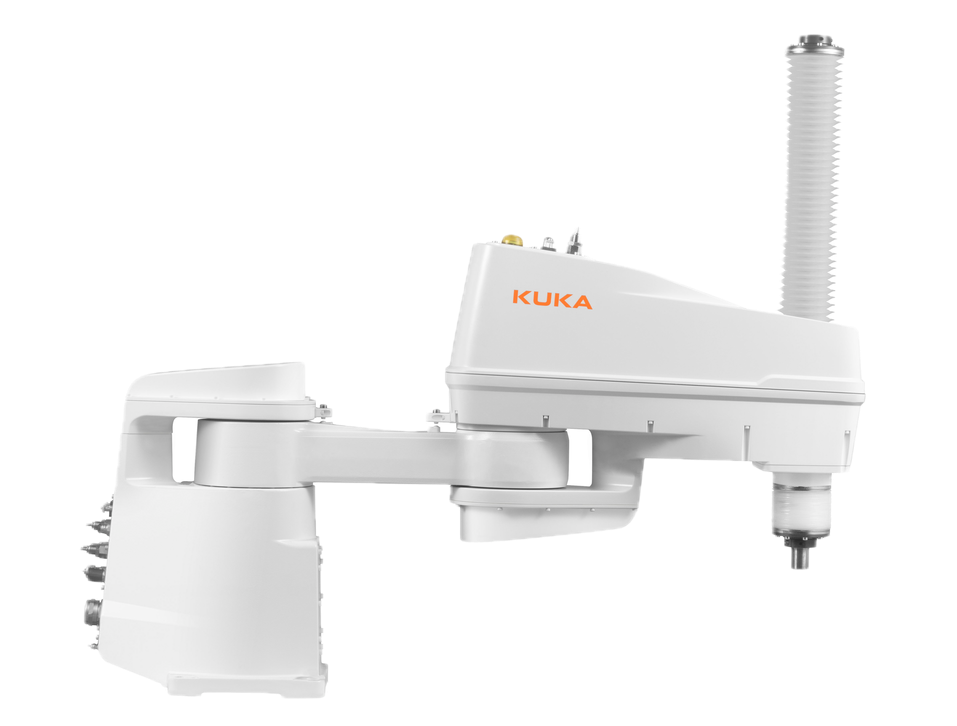

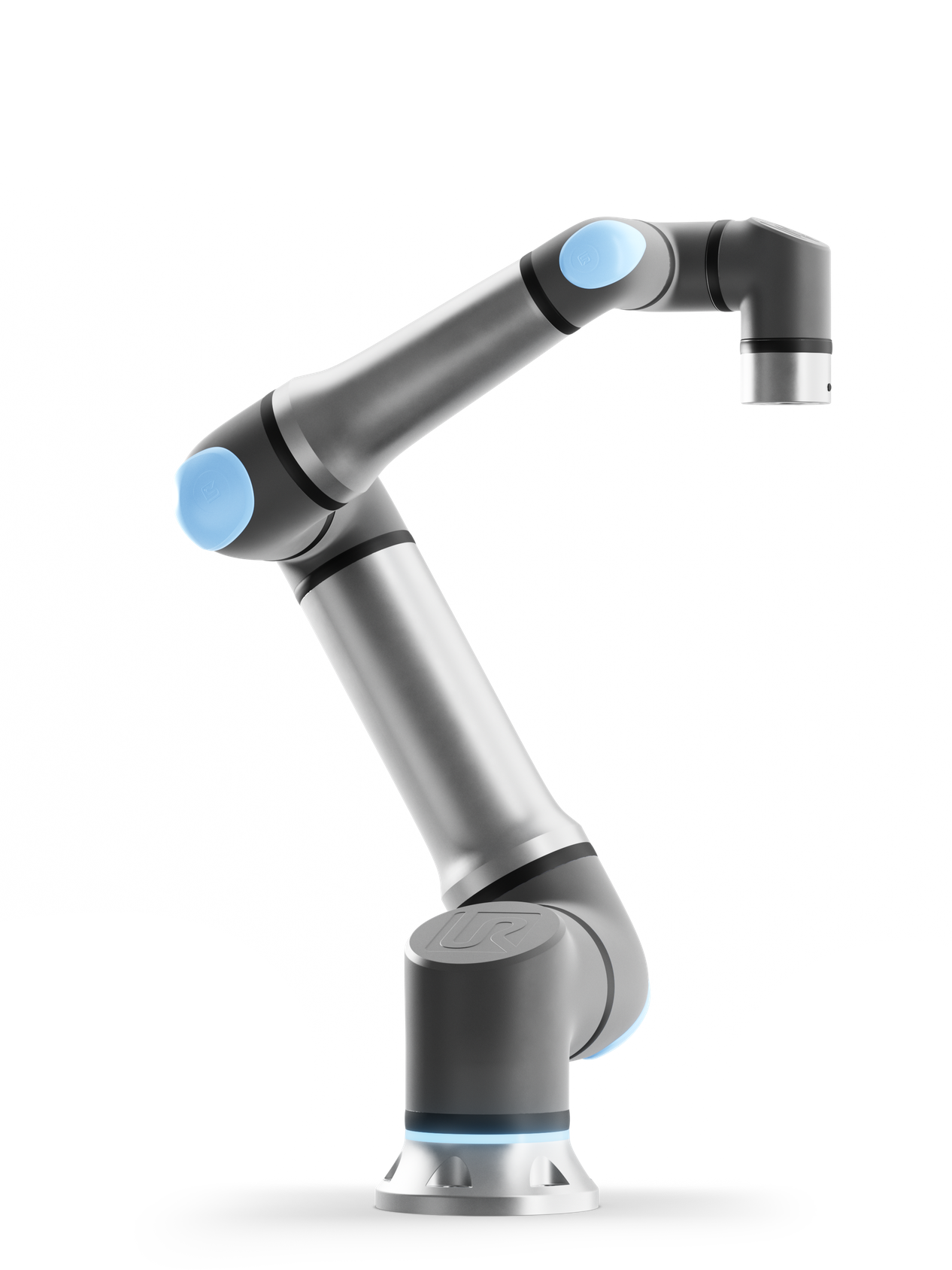

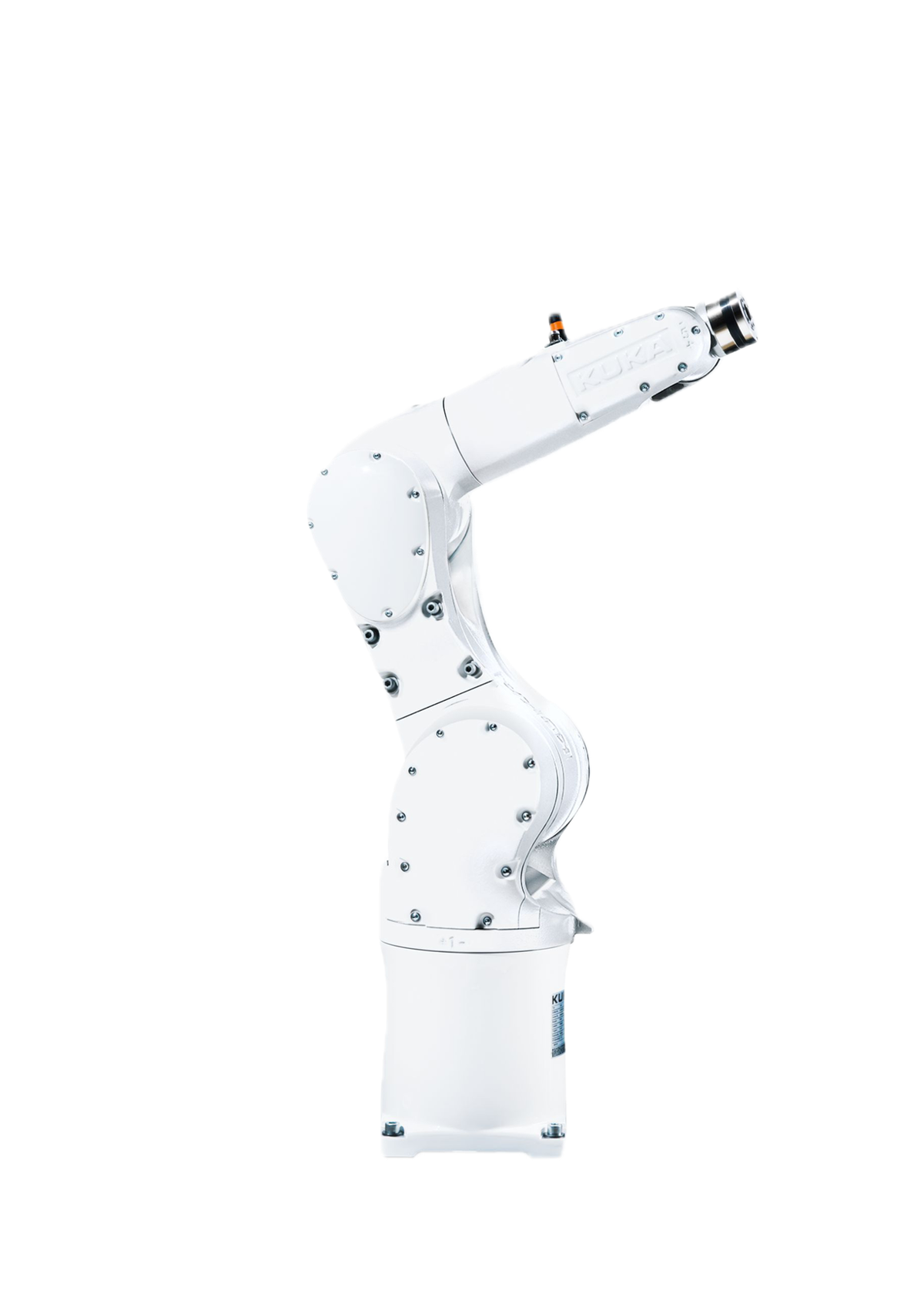

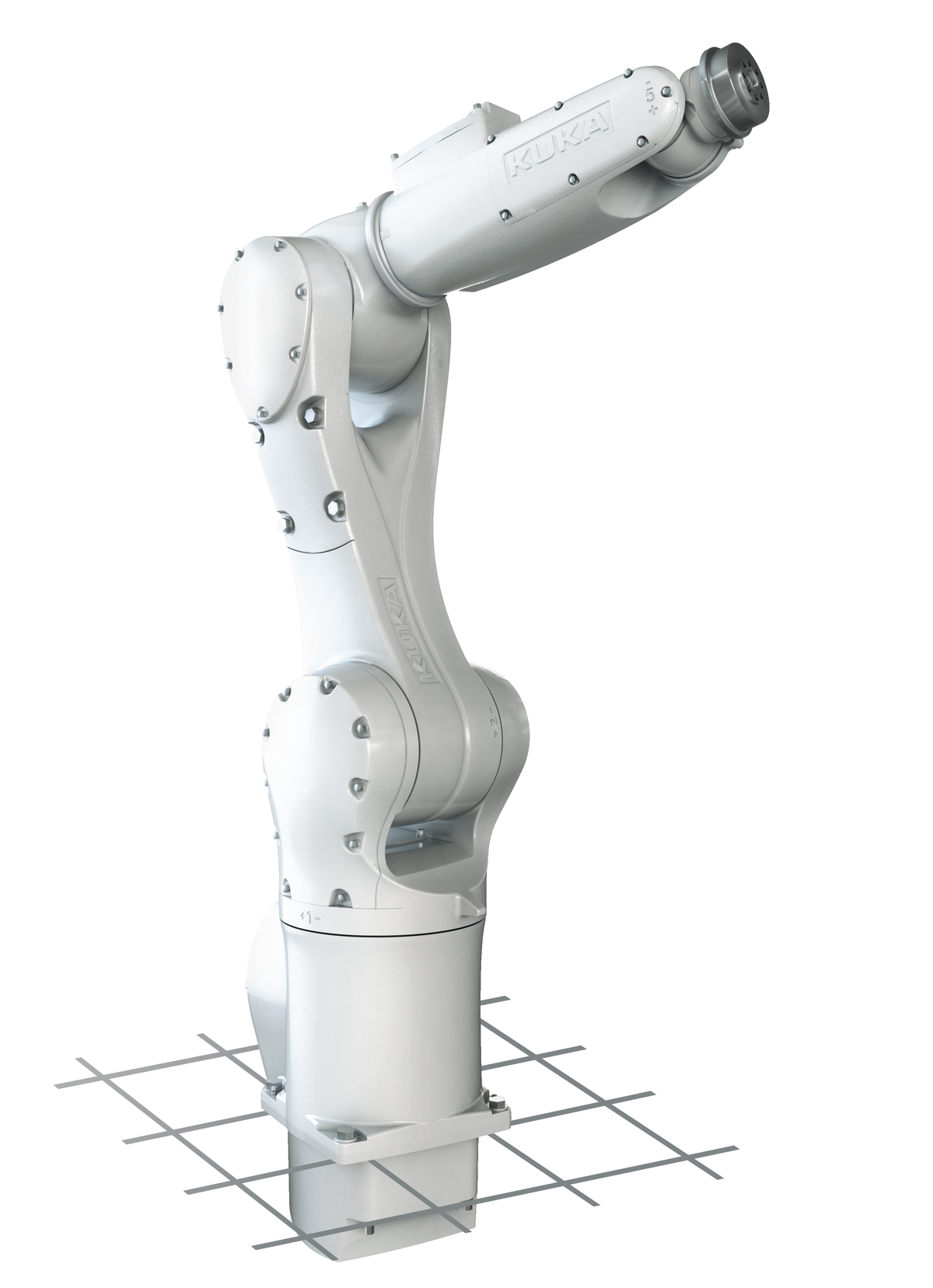

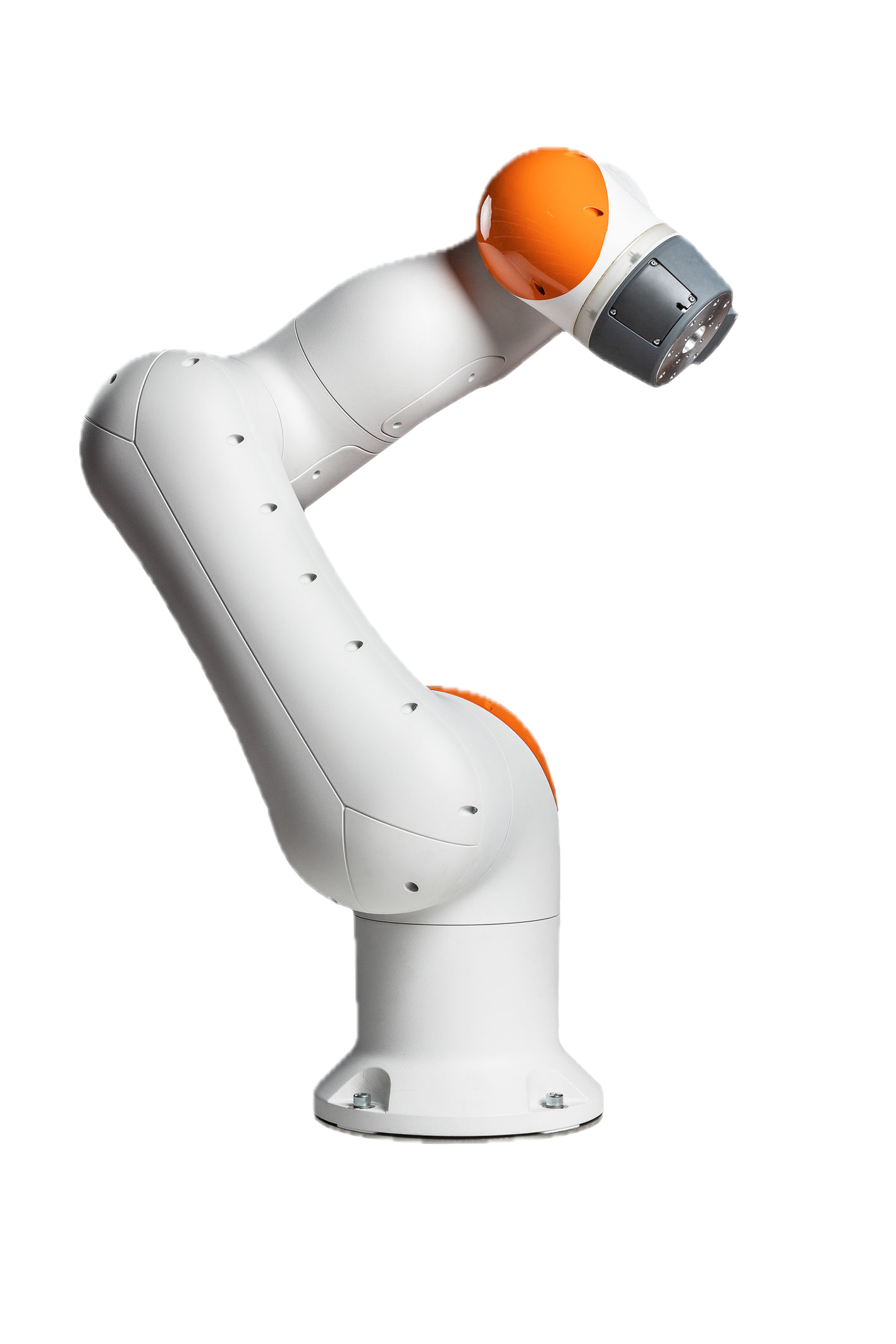

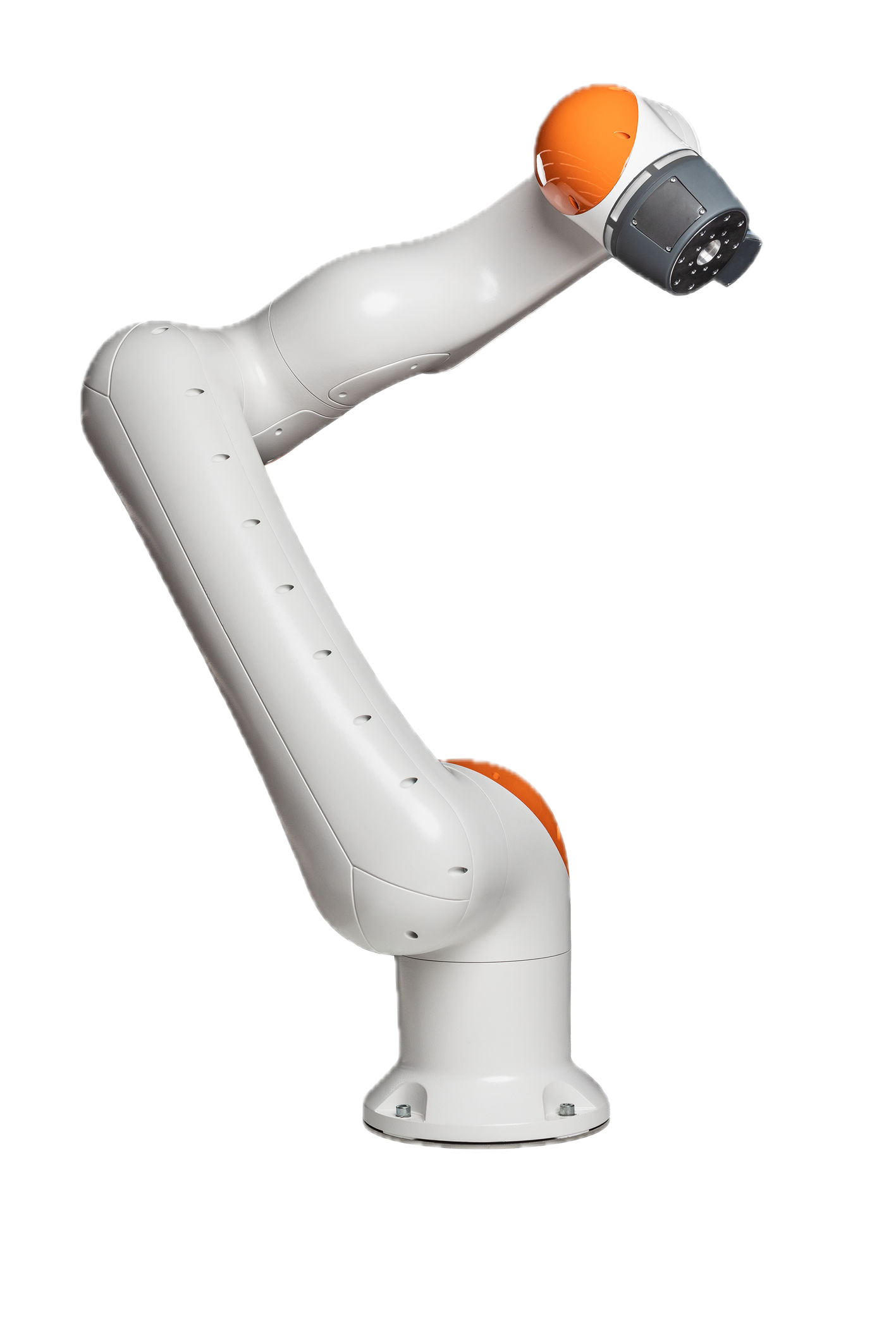

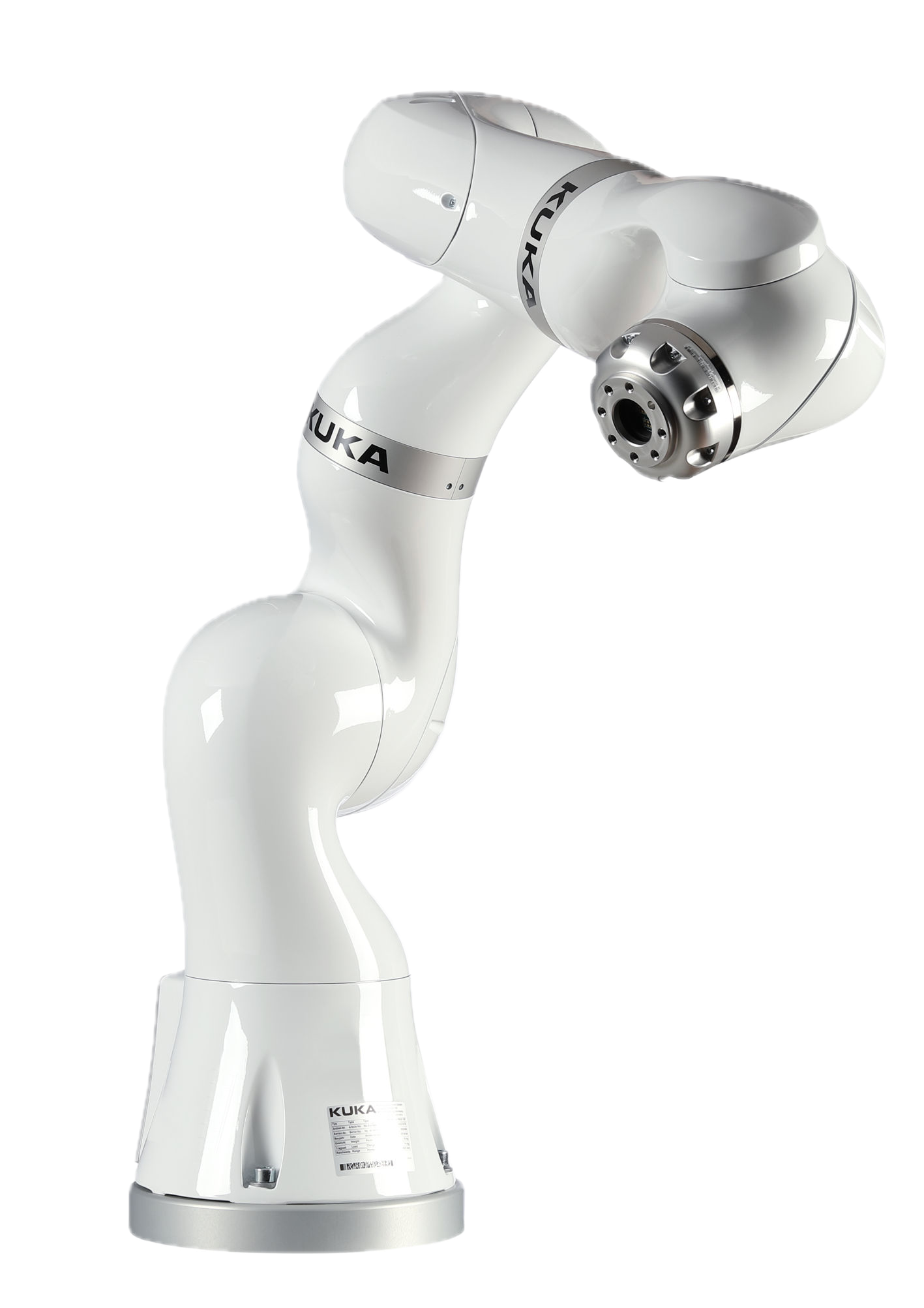

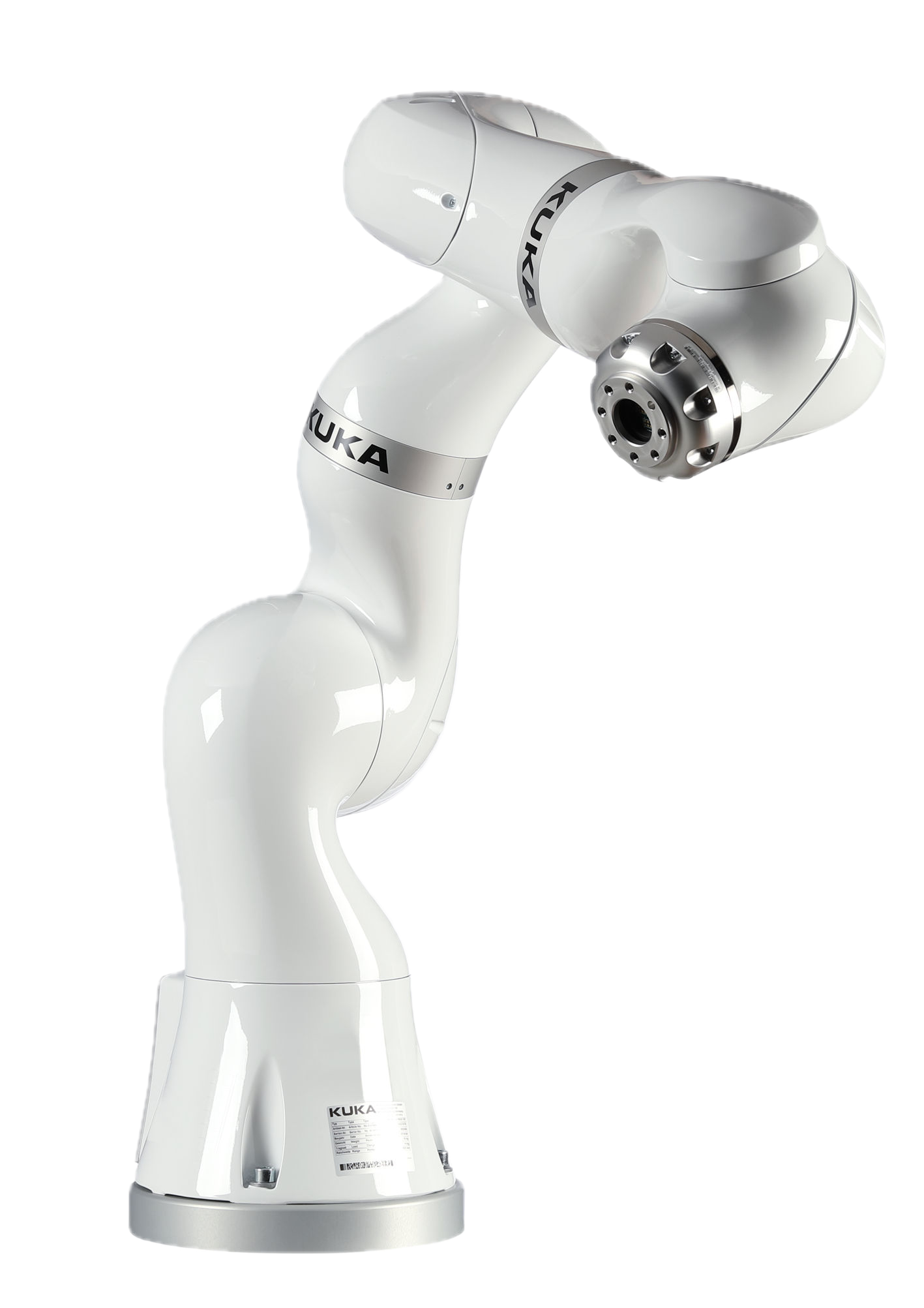

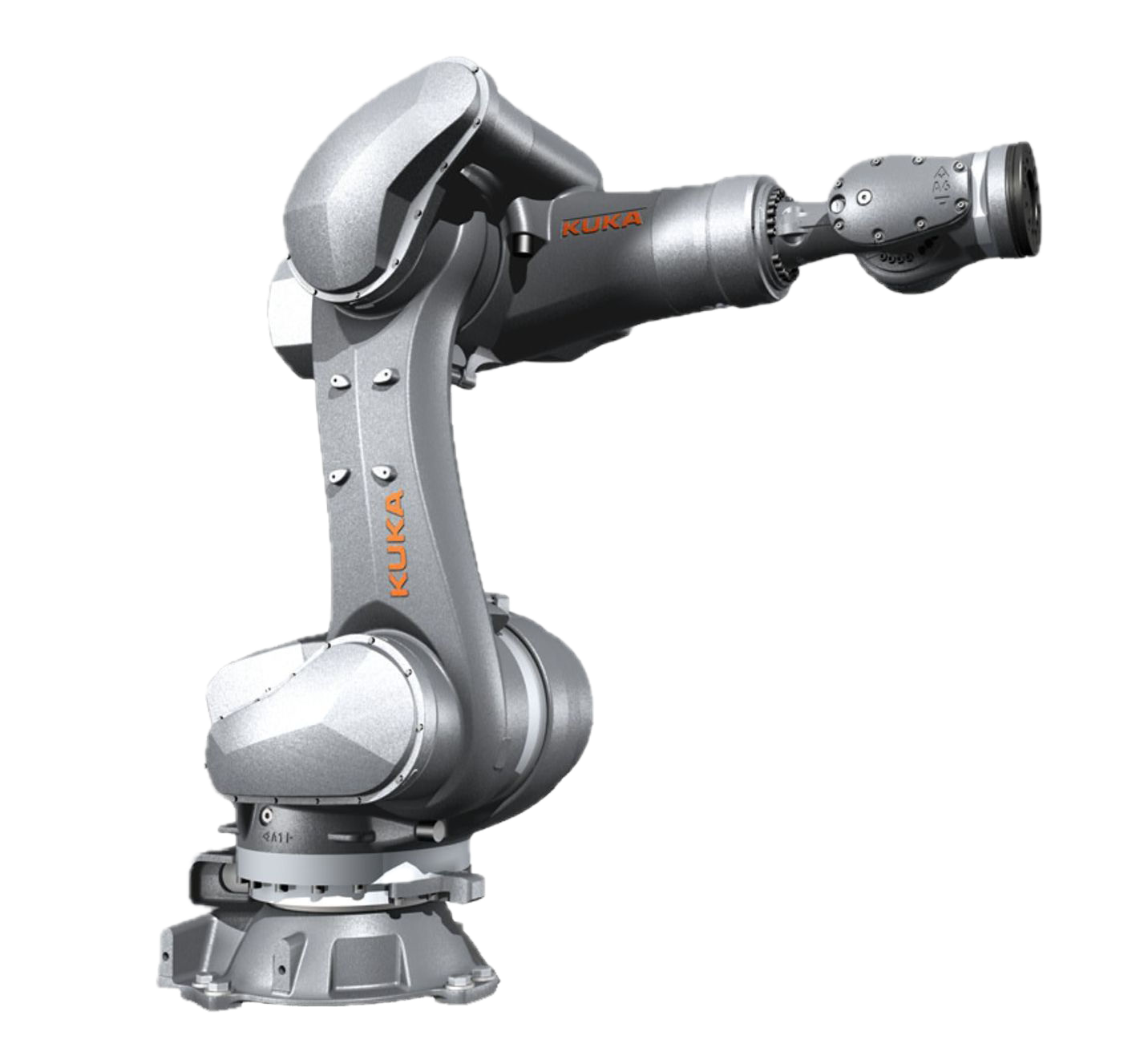

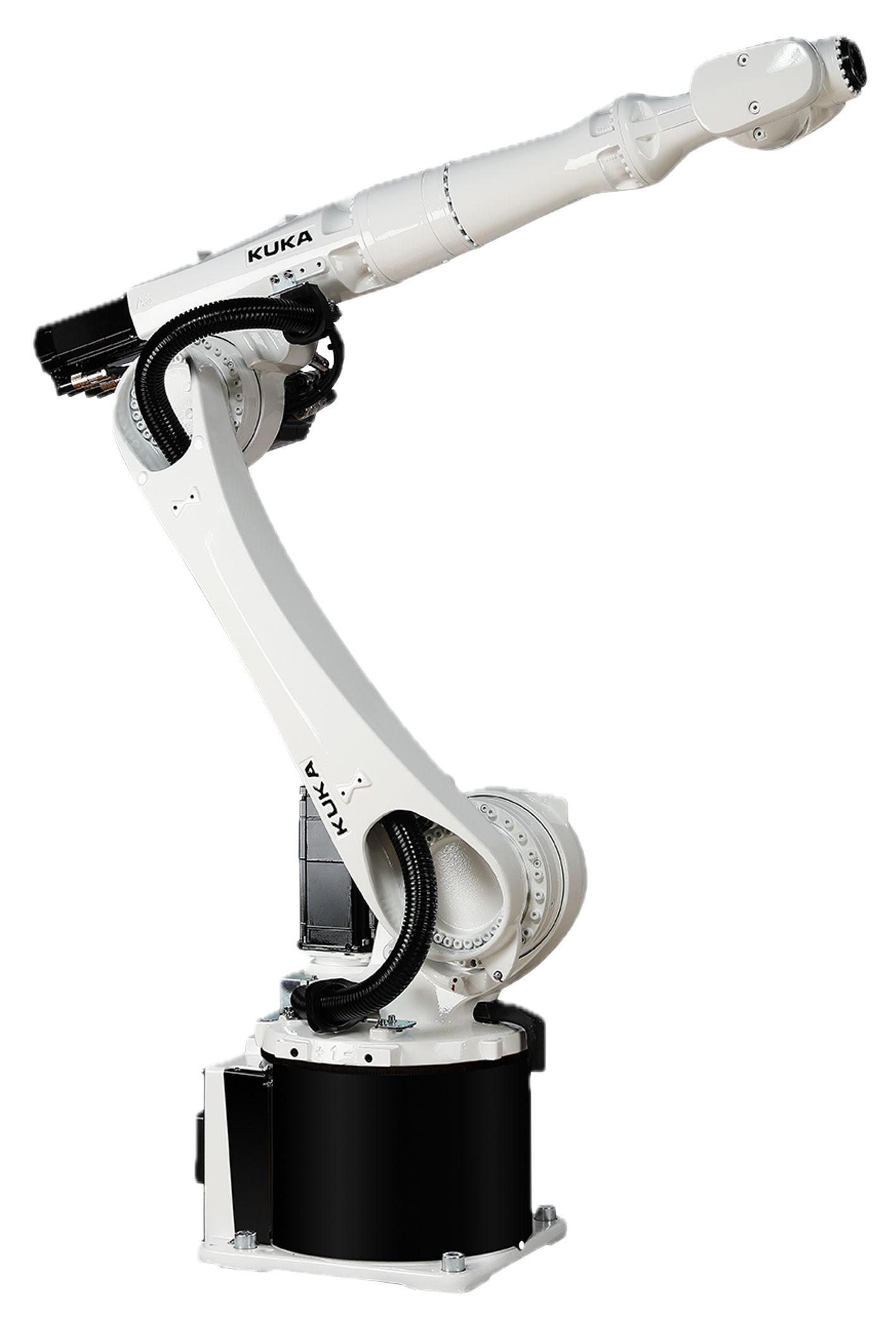

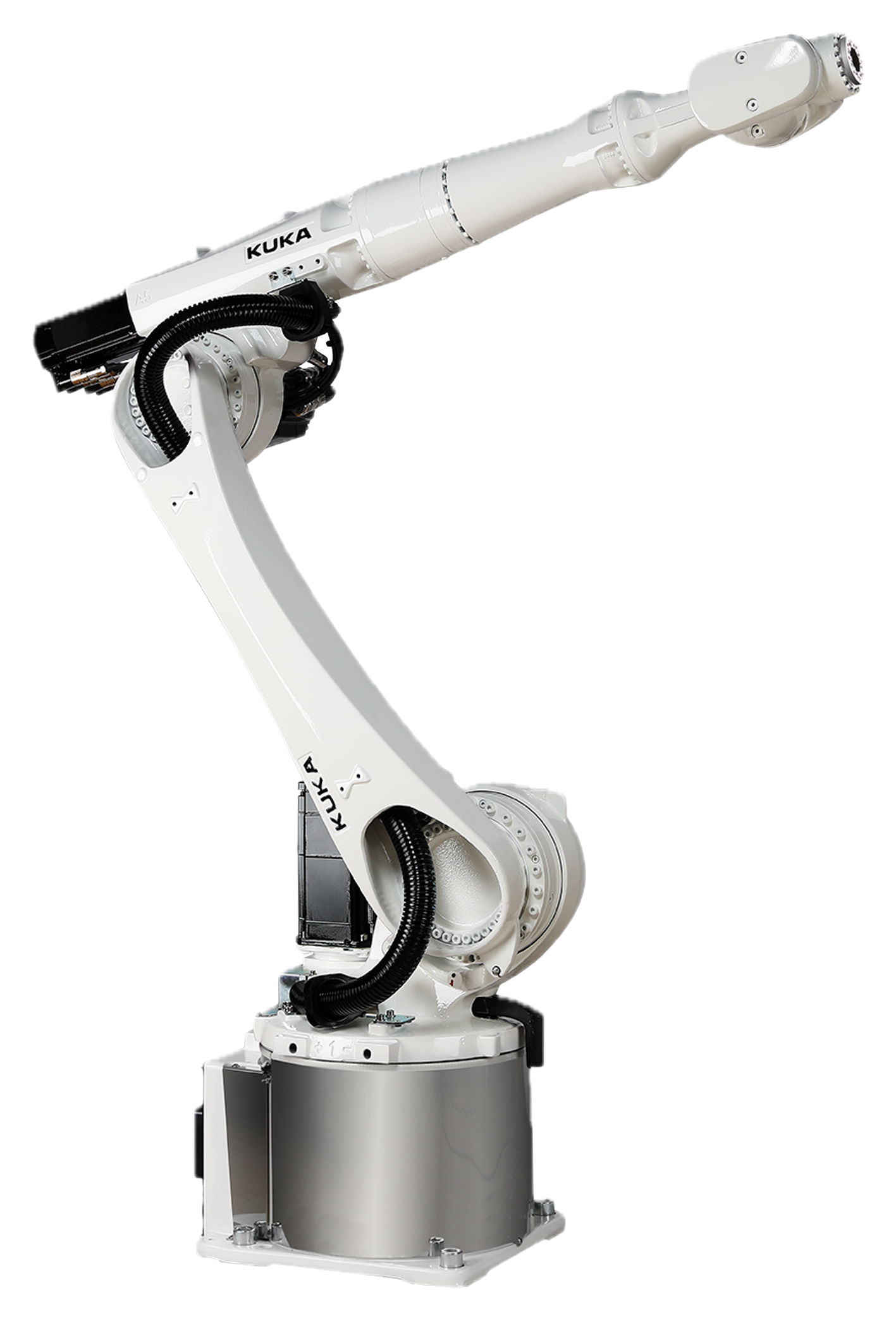

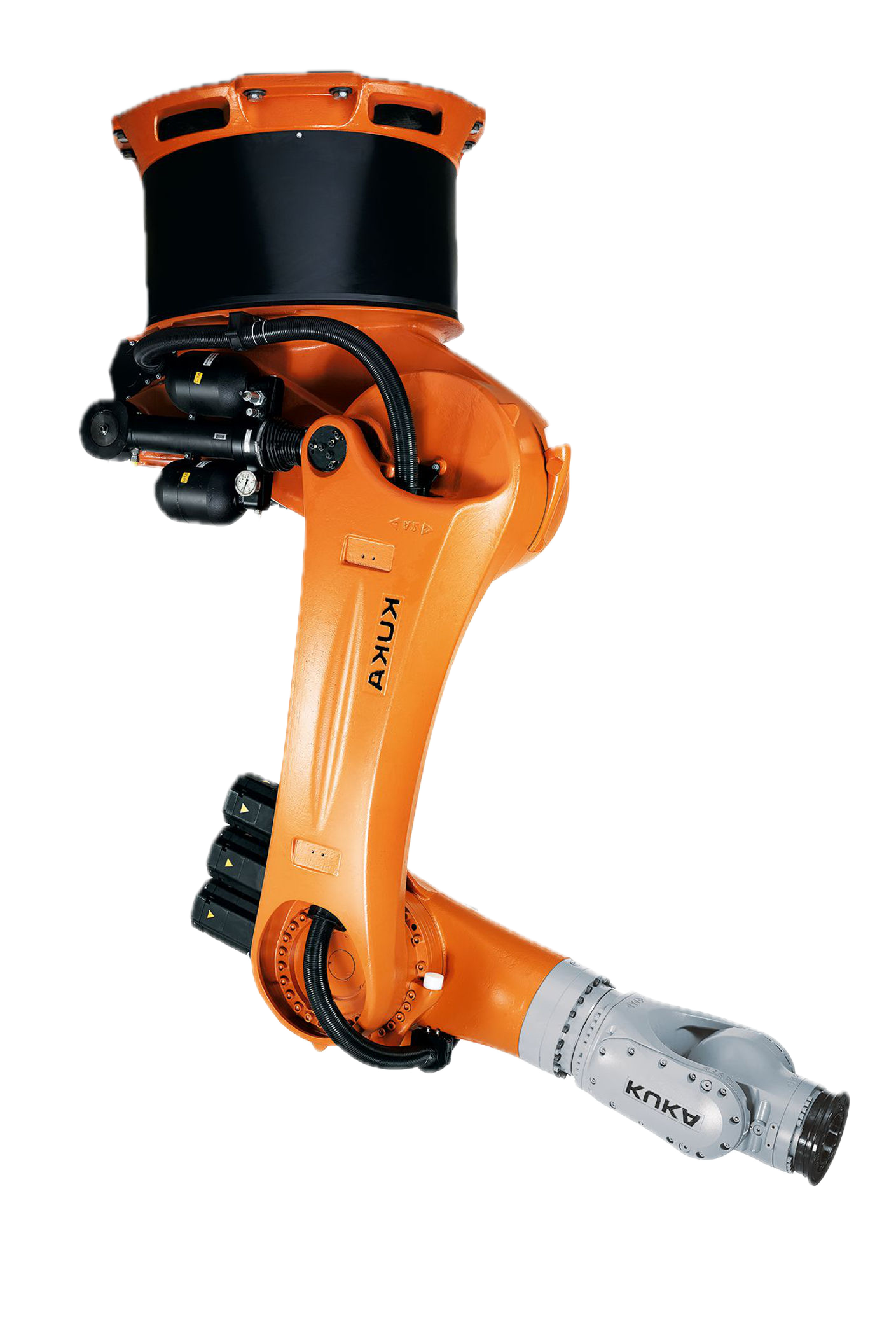

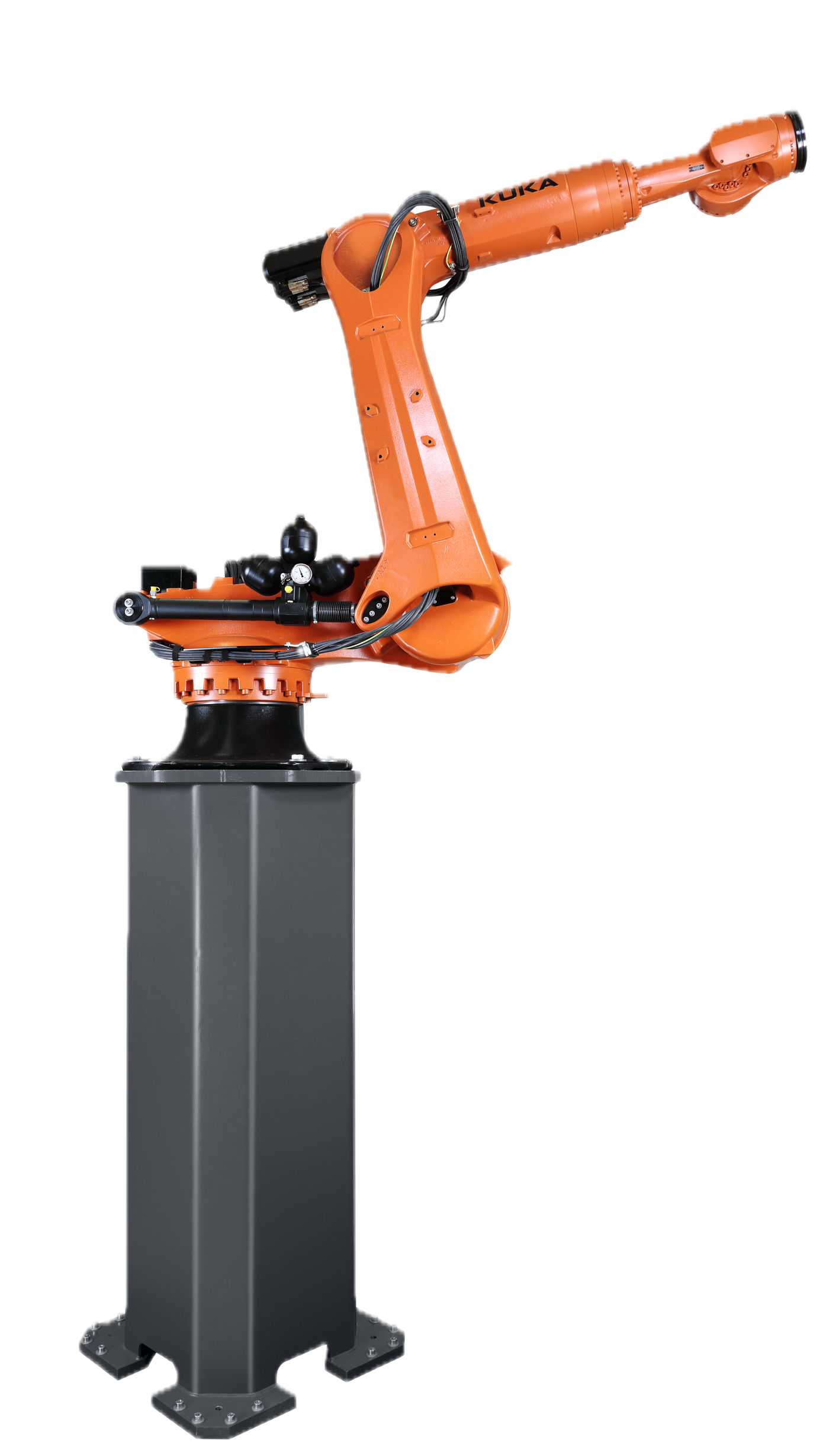

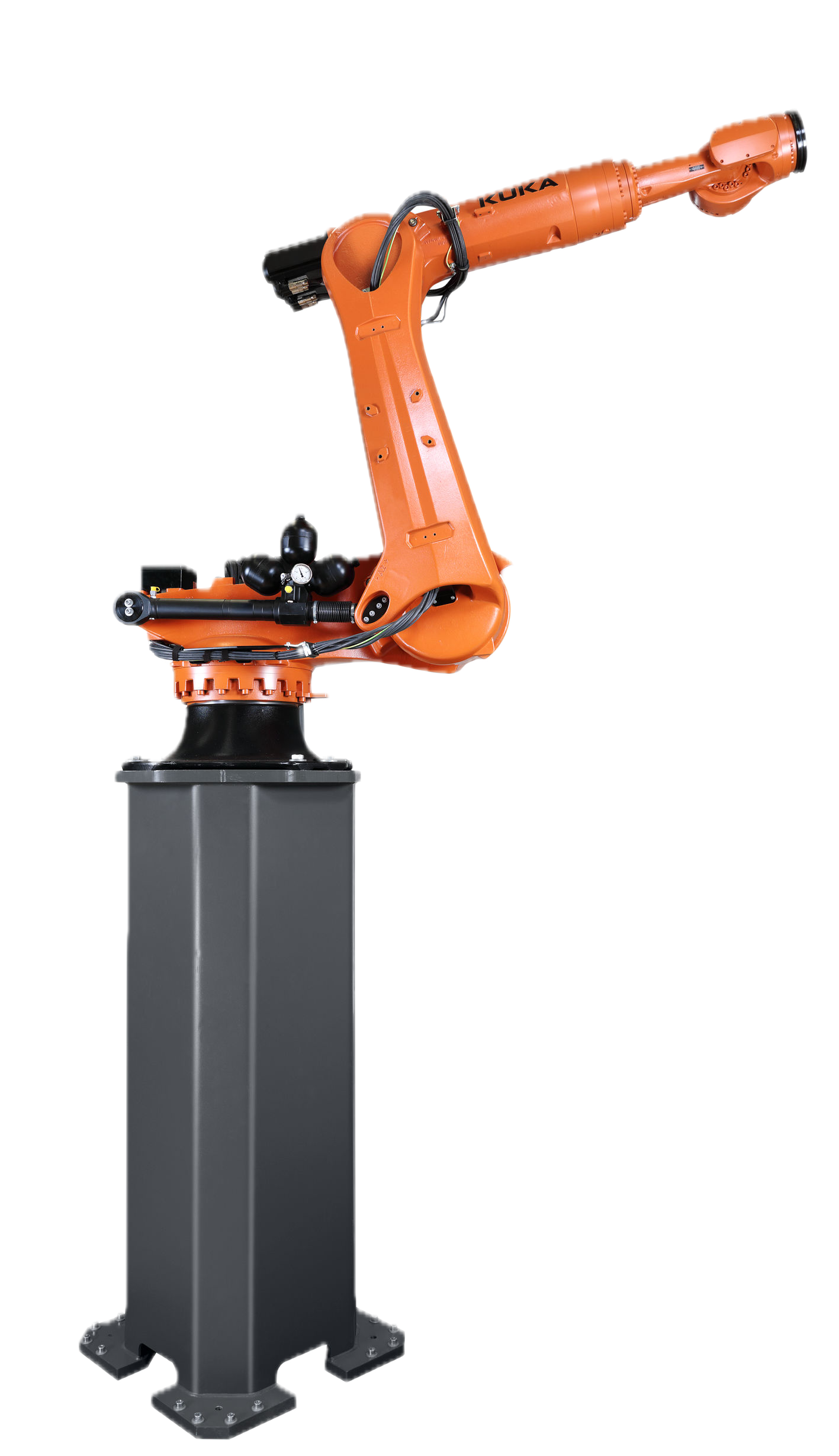

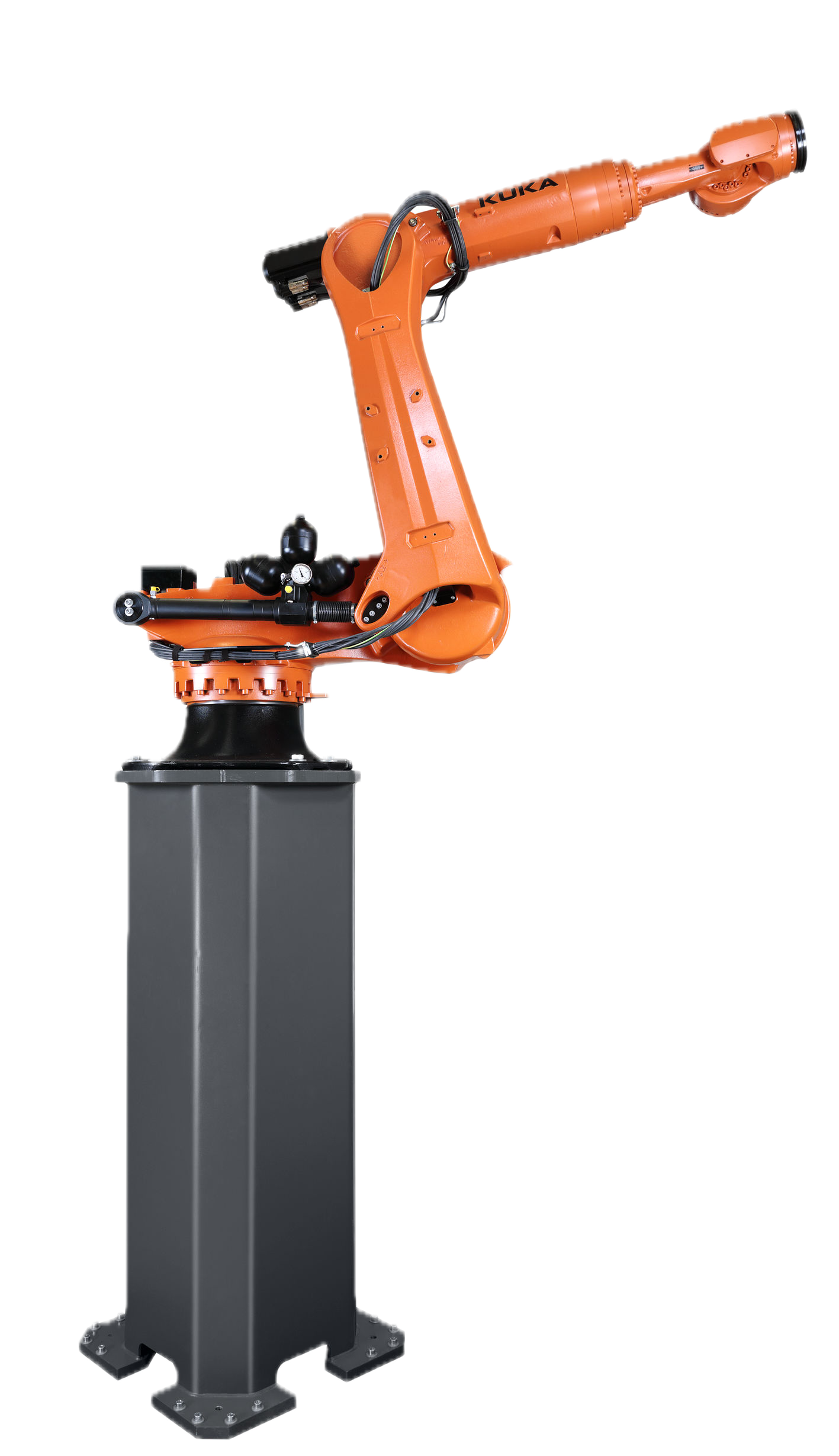

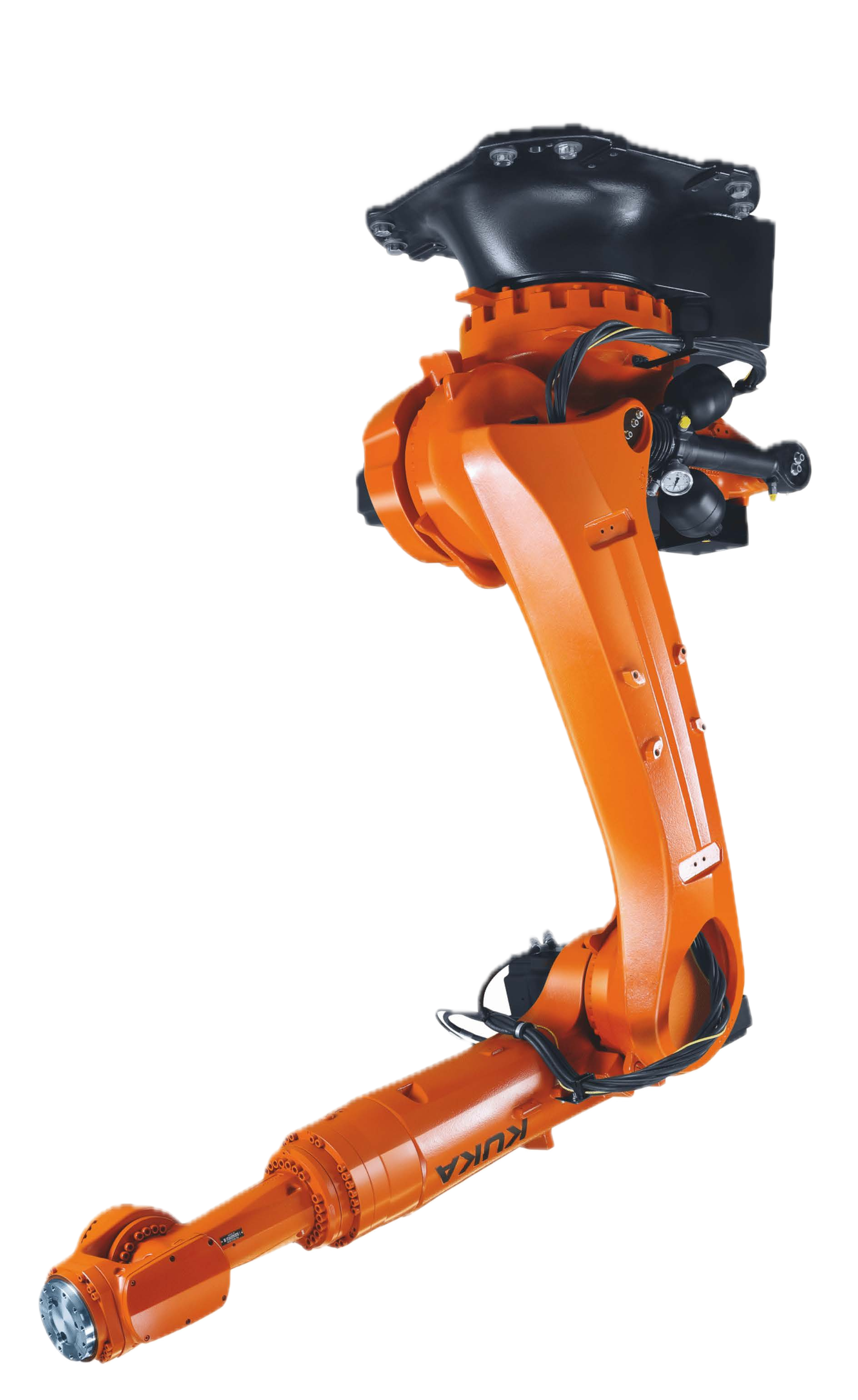

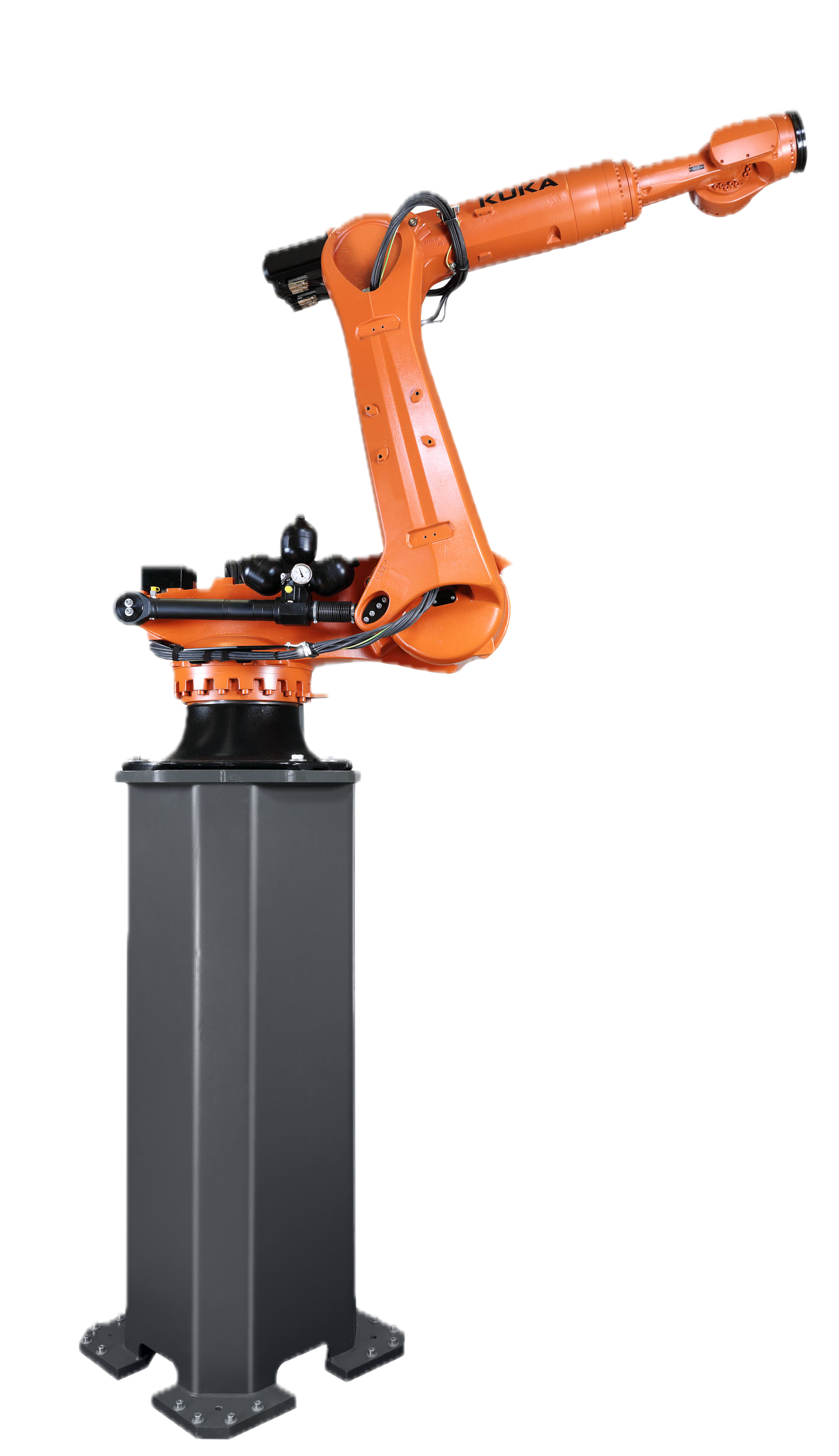

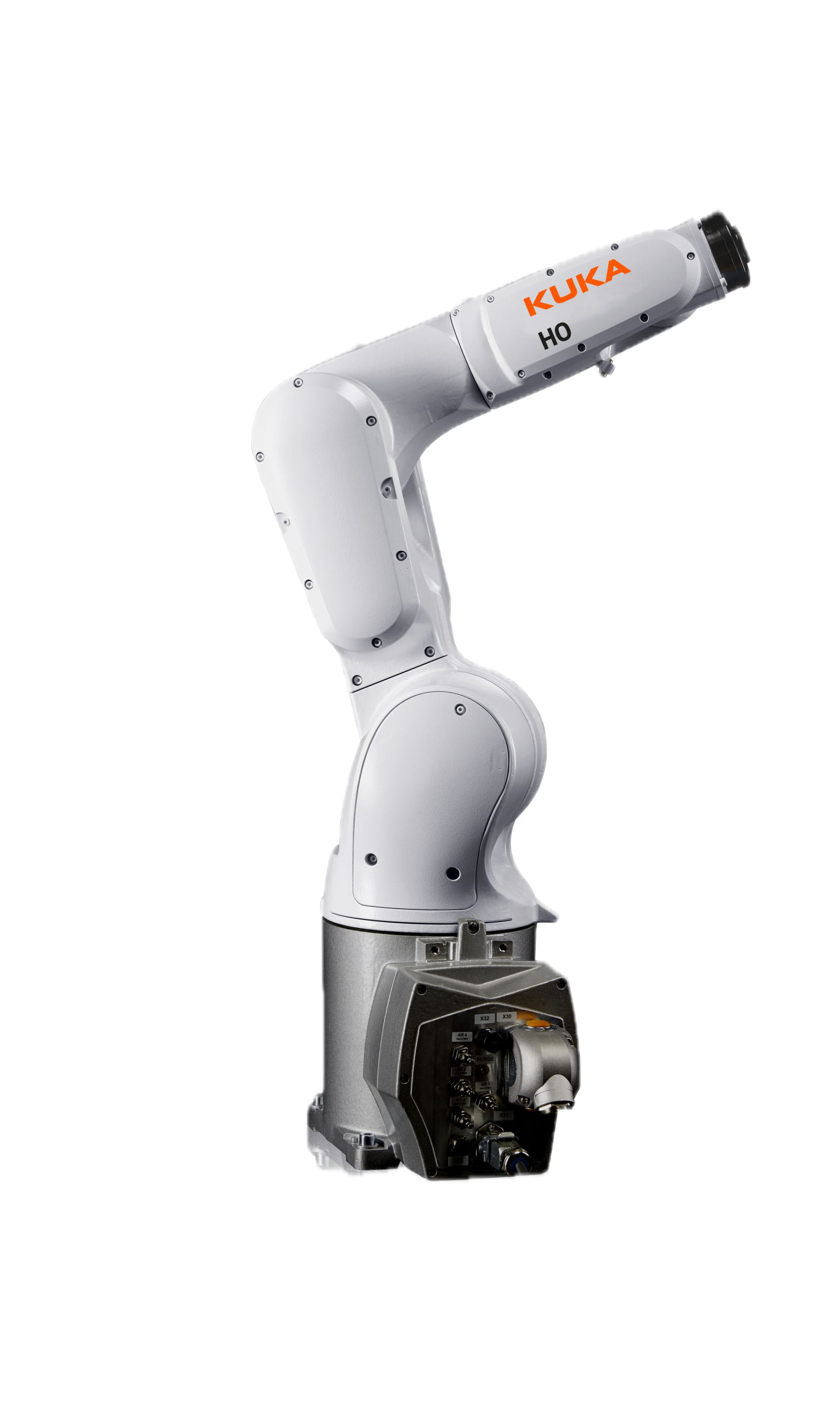

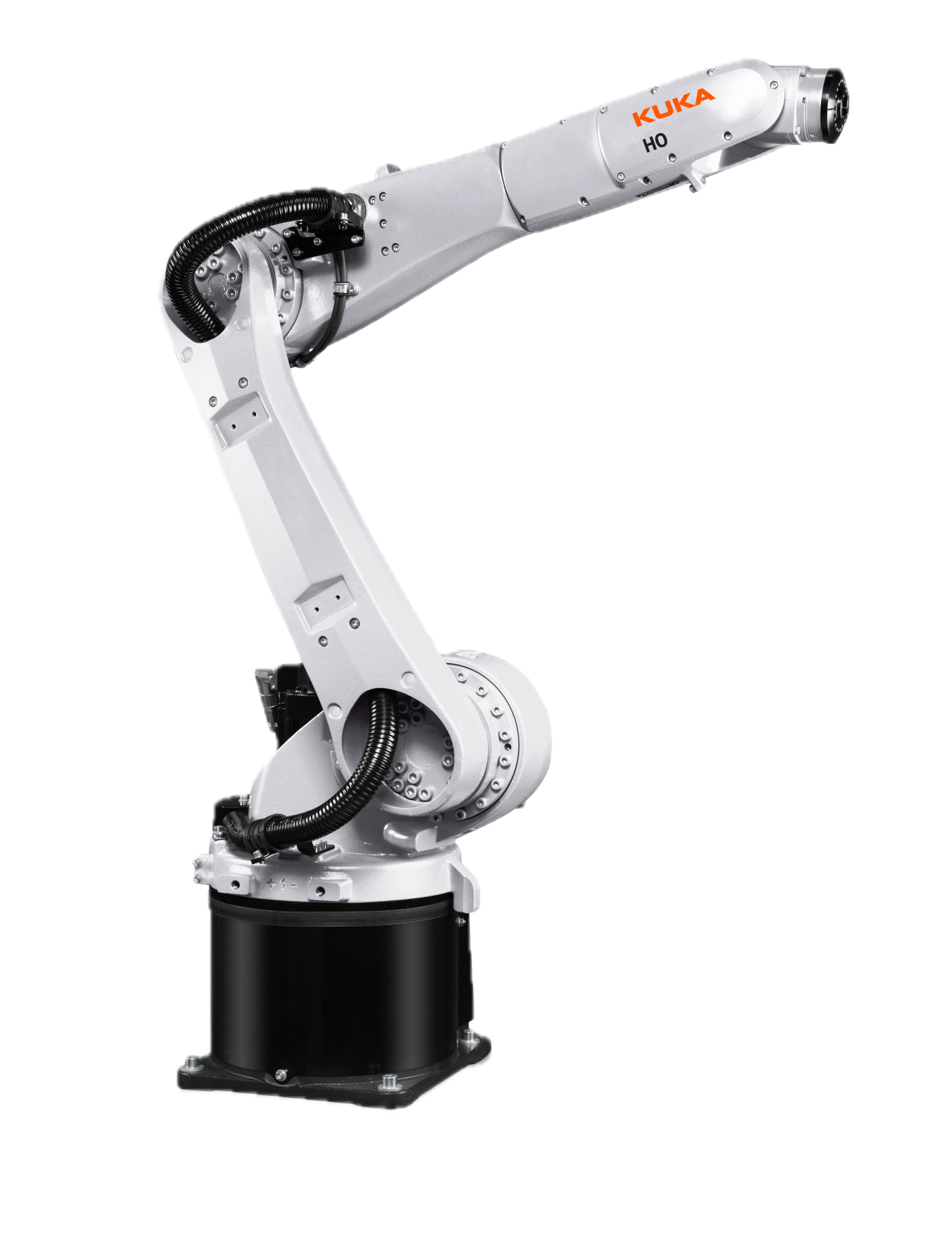

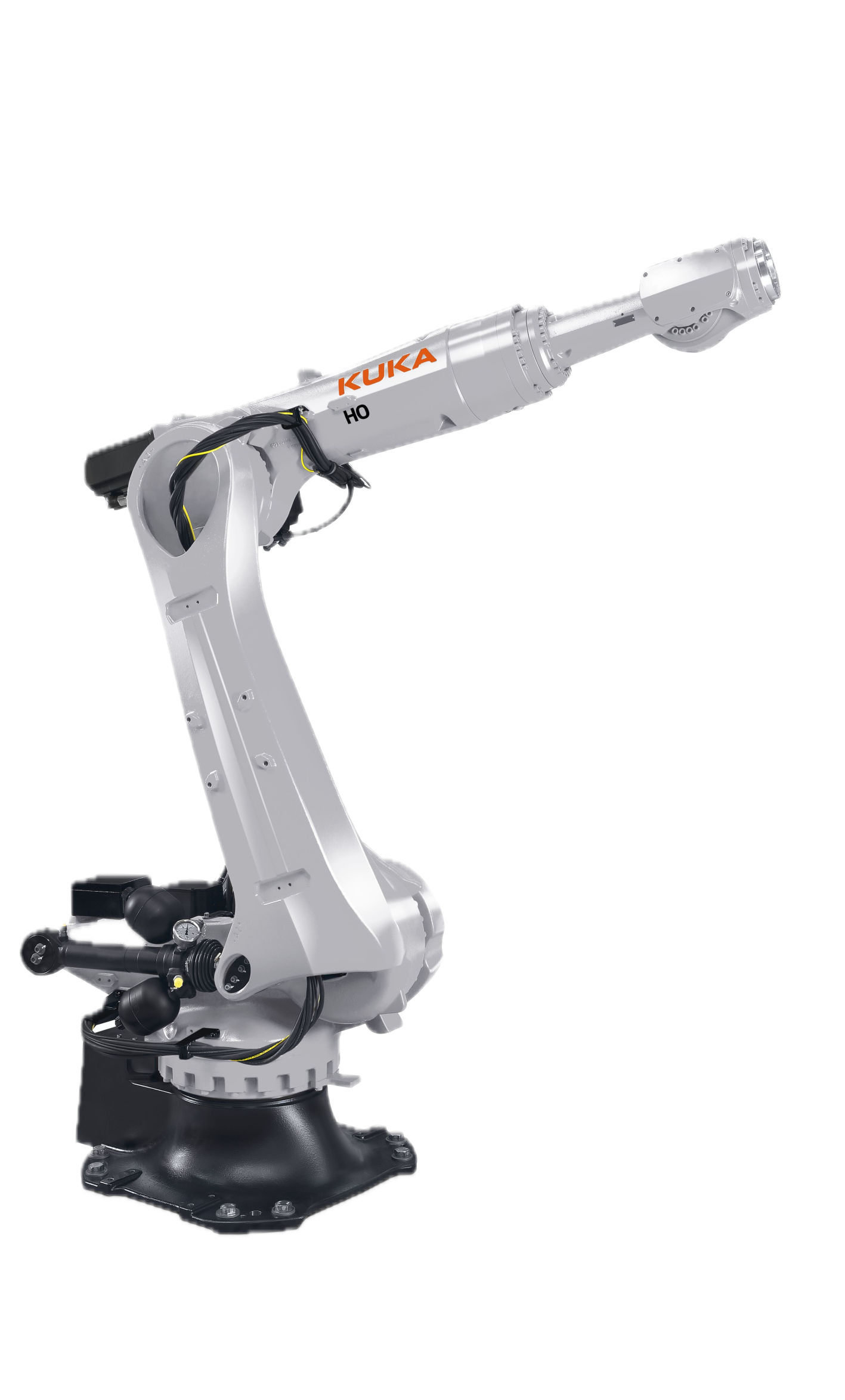

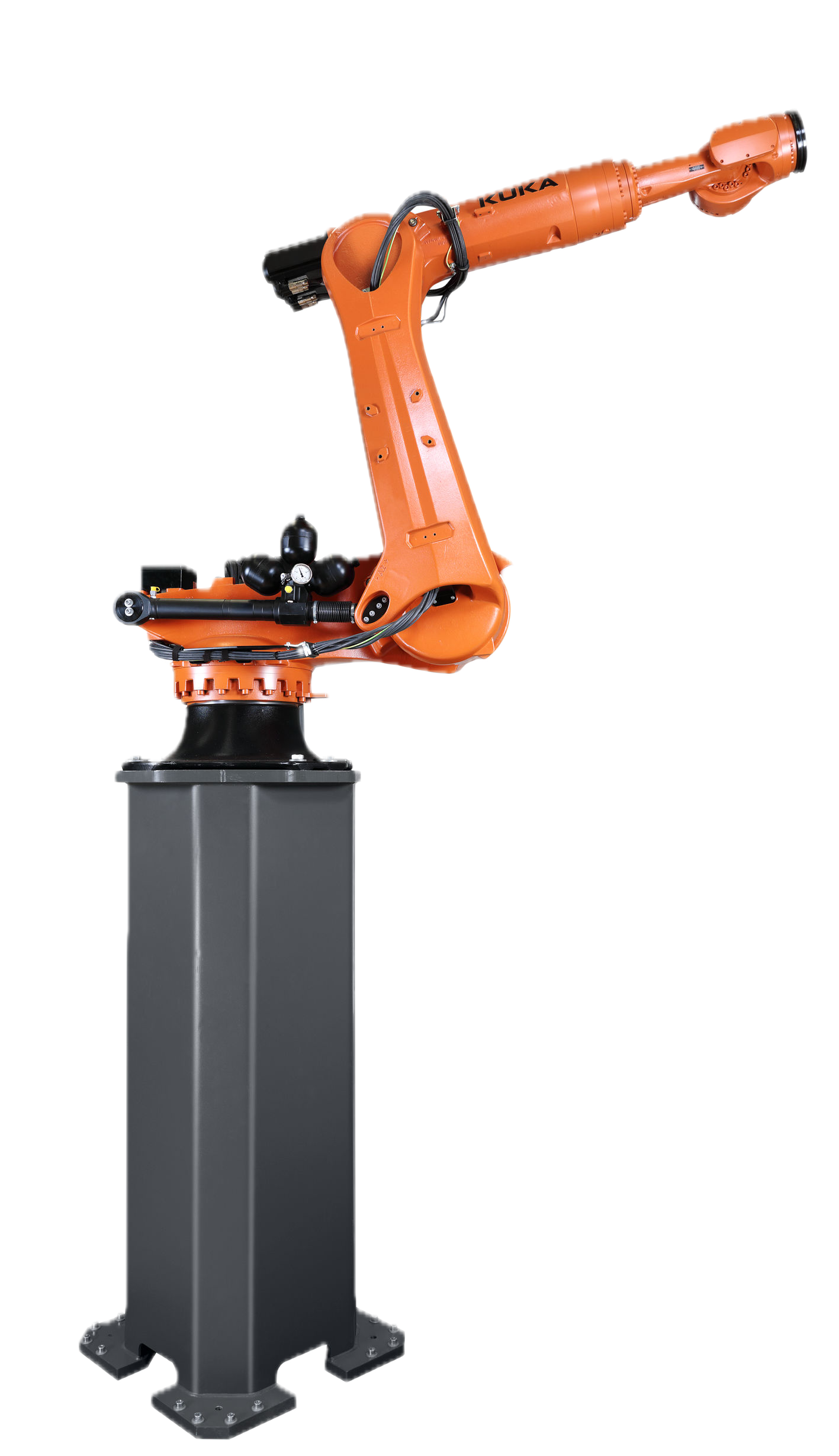

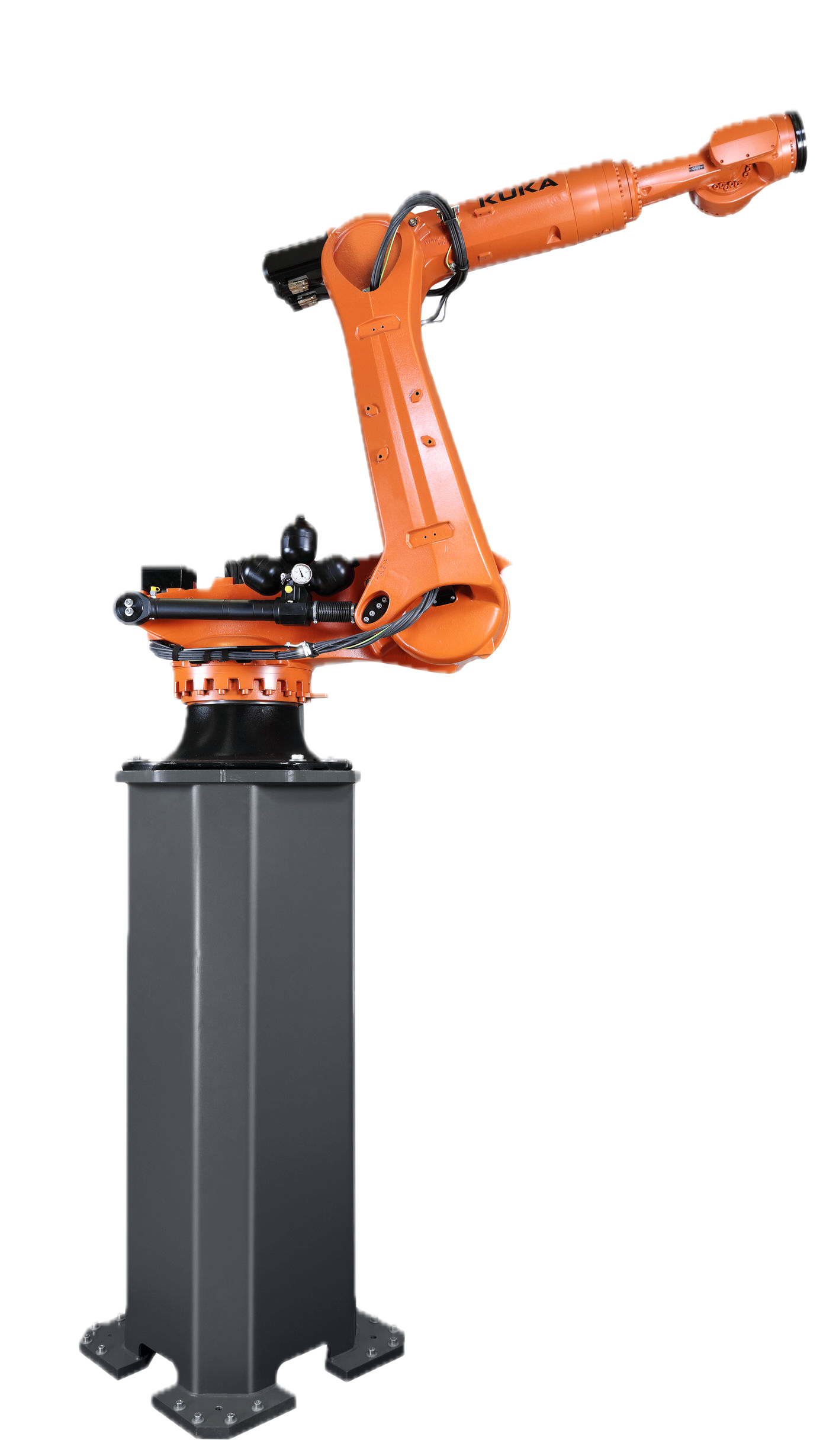

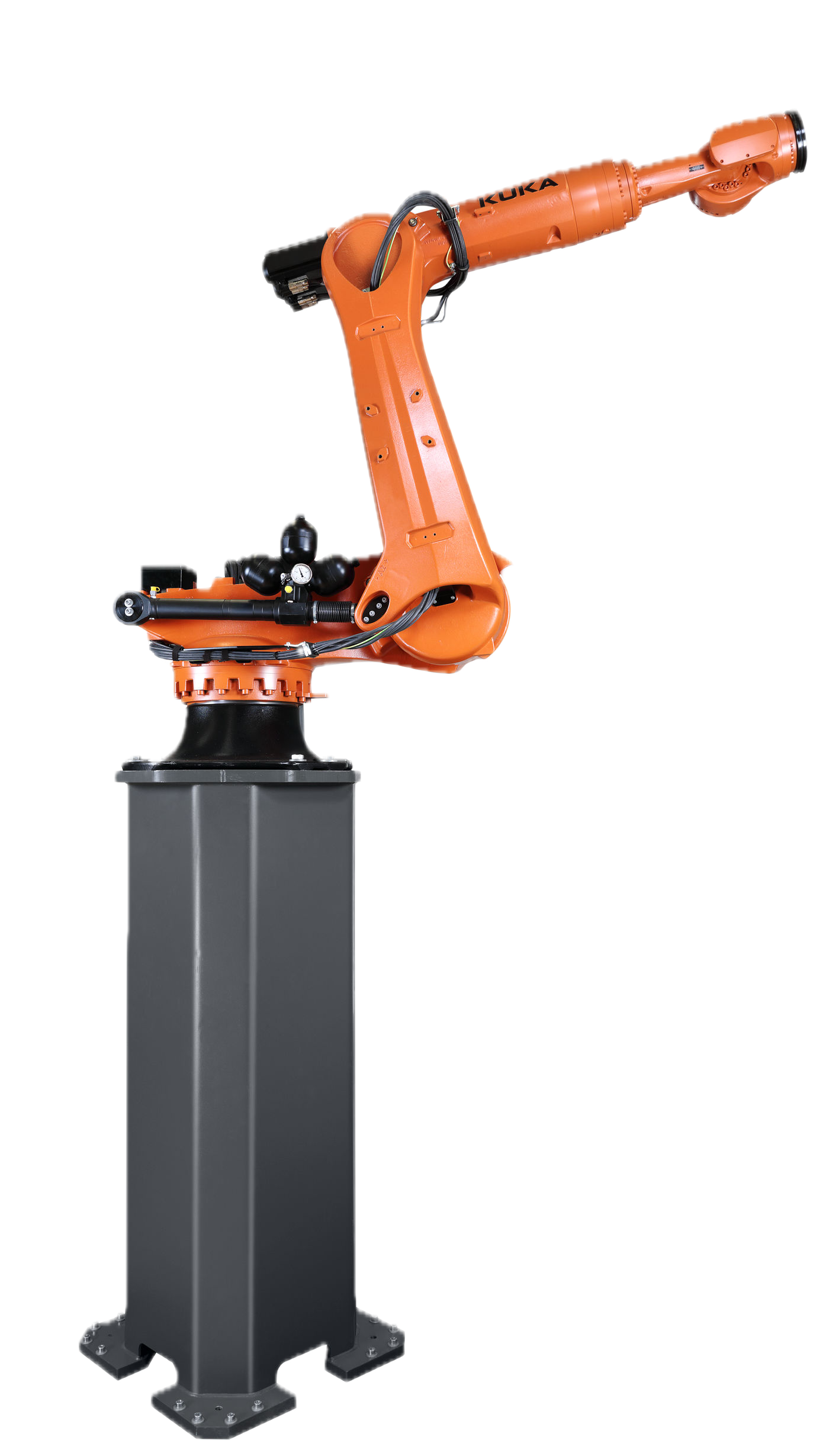

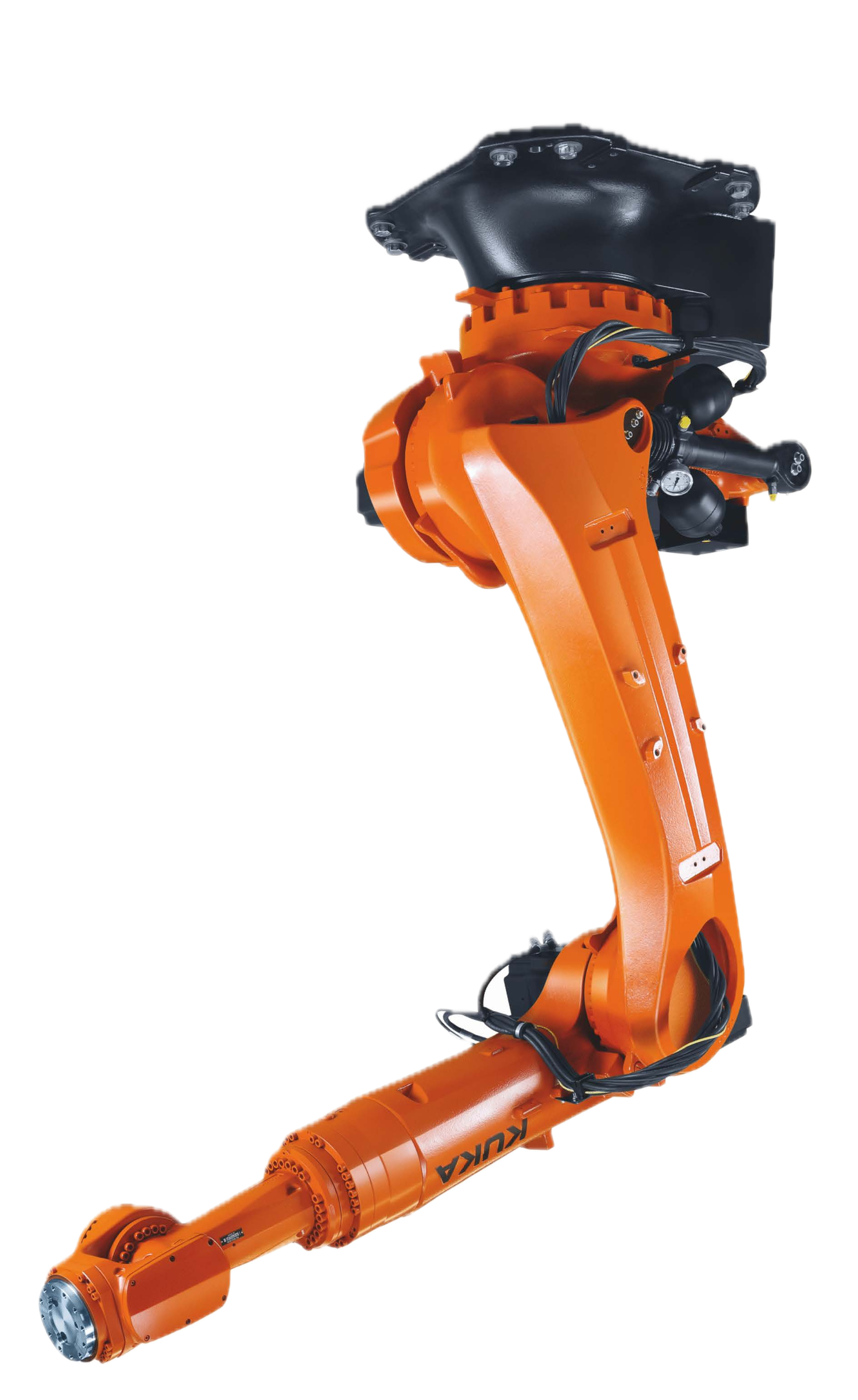

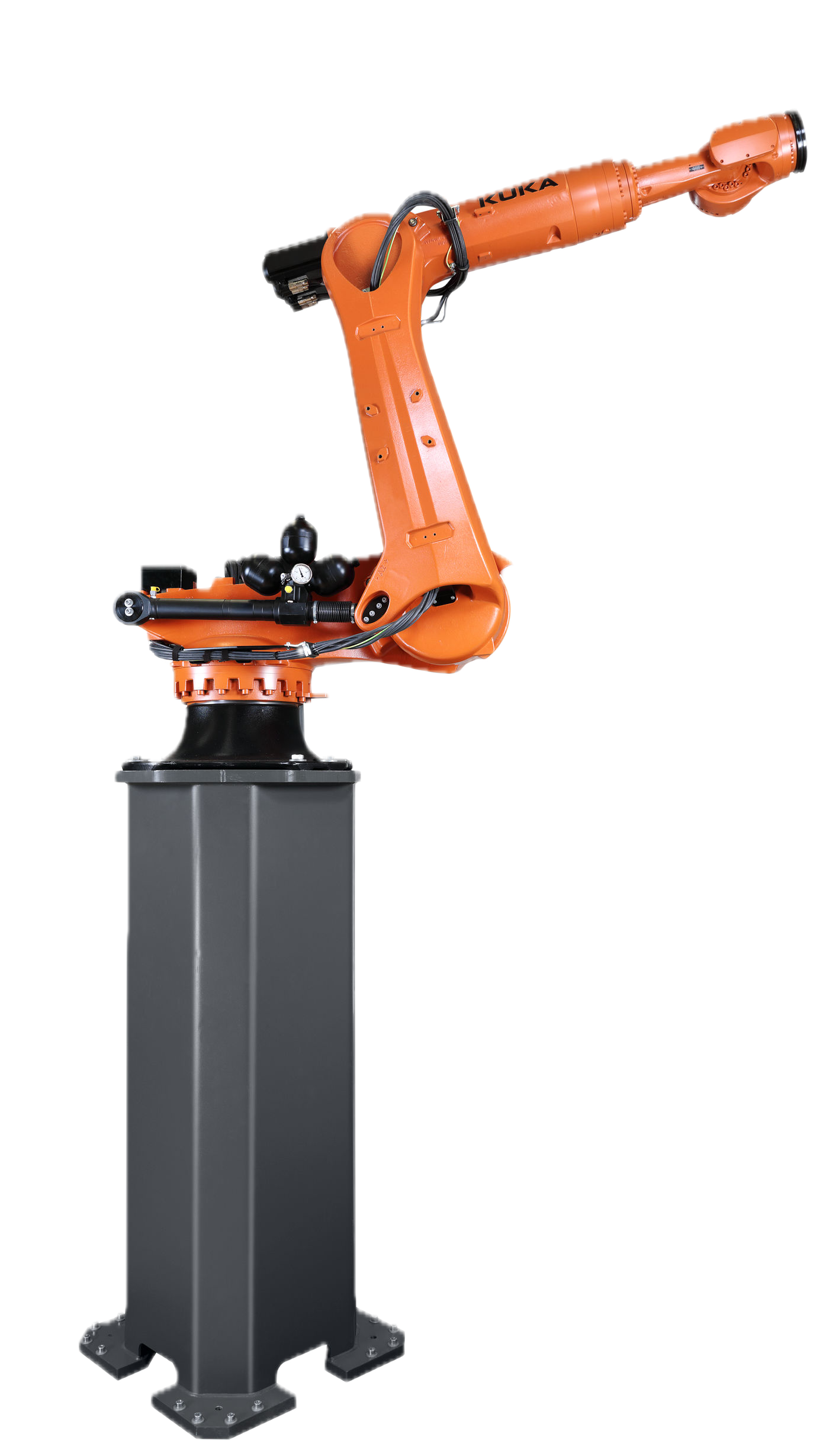

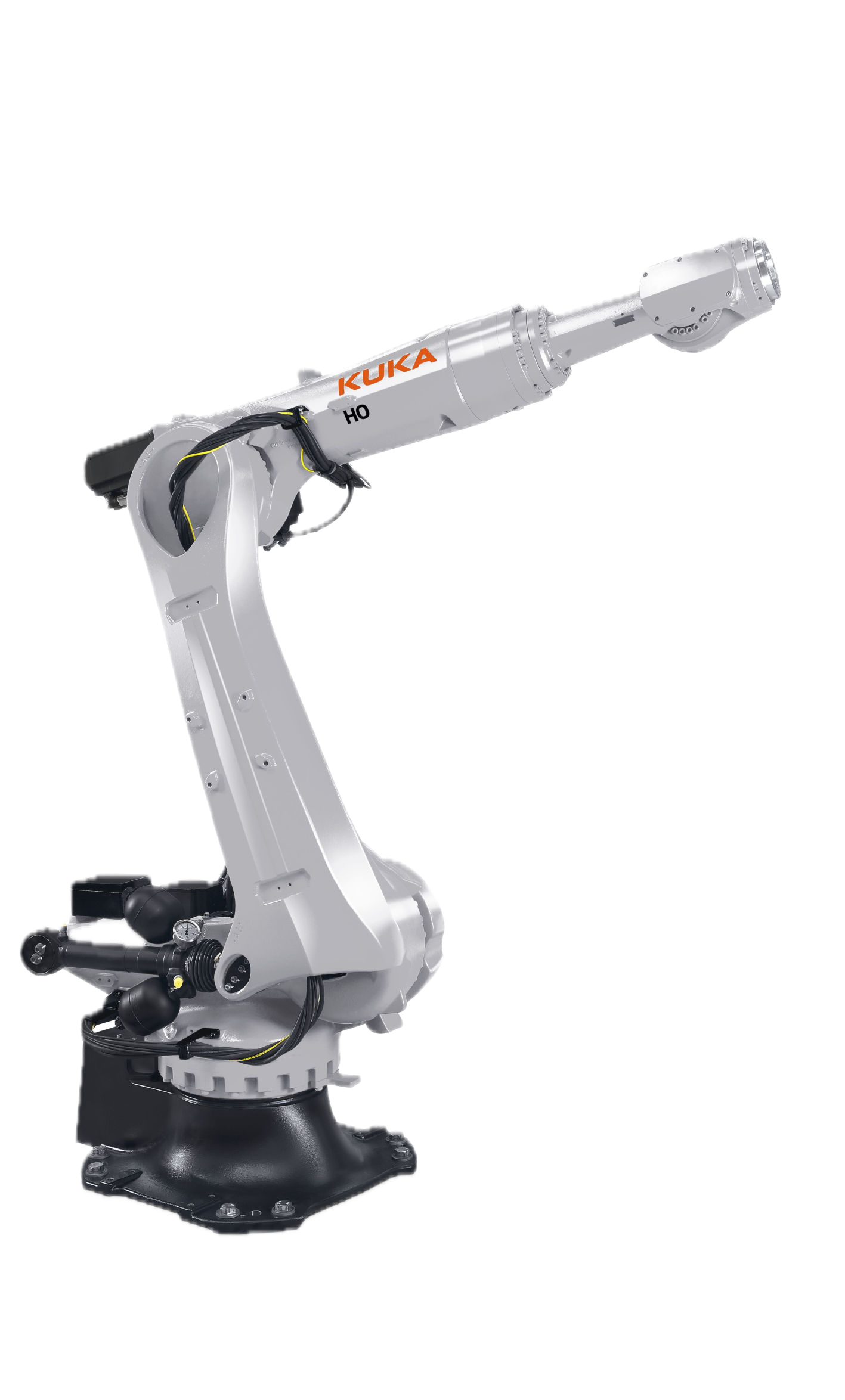

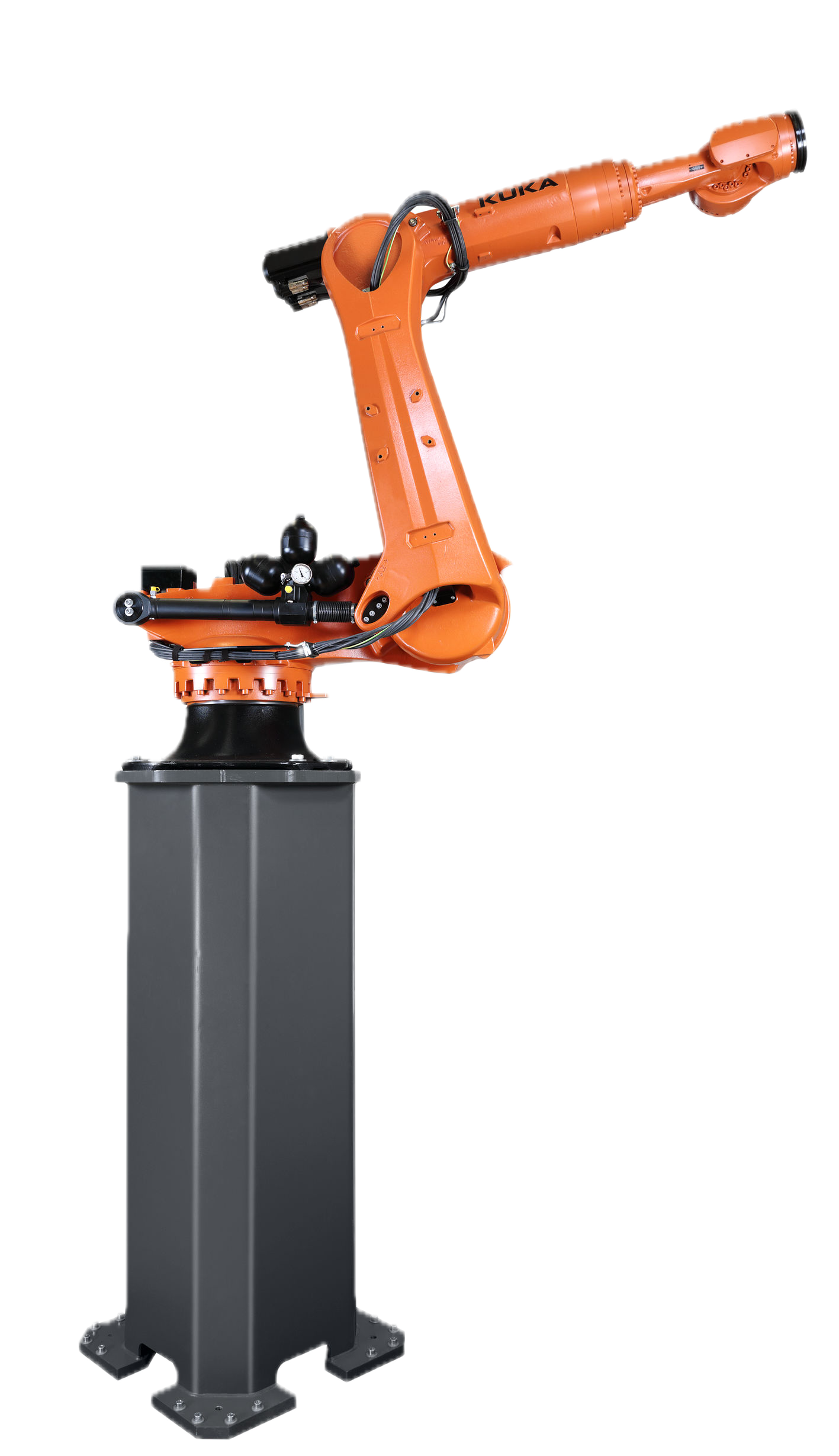

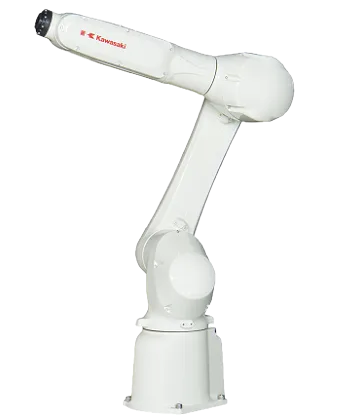

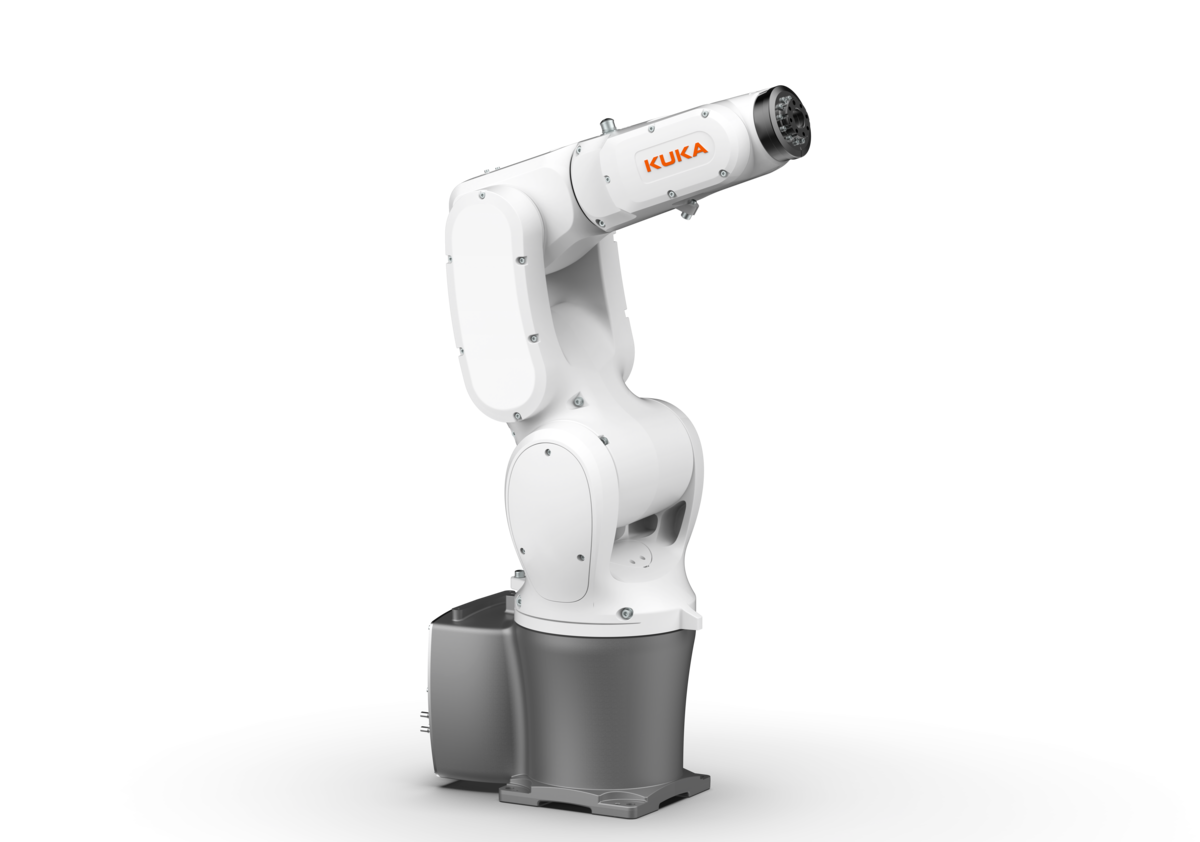

Assembly robots

Contacts

Mon – Fri:

9 AM–8 PM

![[Alt]](/images/logo-min.png)