![[Alt]](/upload/iblock/6c5/b6oqlzcv9w6zt6iy1c7chfo6ki4znvff.png)

Robotic Depalletizing

Solutions

Implement depalletizing robots to enhance your production efficiency.

Robotic depalletizing is the process of automating the removal of products from pallets using industrial robots. These solutions significantly improve the efficiency and safety of production processes, reducing human involvement in heavy and monotonous tasks.

-

30% Reduction in

production

costs -

20 years

years average

lifespan of operation -

24/7depalletizer

robot operation -

1+ years

average return

on investment

![[Alt]](/upload/iblock/b00/he8fbtfcx70po59k1loqvci0an3shnvb.png)

Industries

Depalletizing robots are used in enterprises that need to handle large volumes of incoming products where there are high demands for speed and accuracy in the depalletizing operation.

Consumer goods production:

Depalletizing automation is in demand in the production of food, beverages, household chemicals, and cosmetics.Construction:

Using robots to move construction materials helps increase construction speed and reduce labor costs.Logistics and warehousing:

Robotic systems help optimize unloading and loading processes in warehouses and logistics centers.

Robotic depalletizing solves tasks

Implementing a depalletizing robot can be advisable in the following situations:

High volume of work:

When the number of pallets that need to be unloaded daily exceeds the capabilities of manual labor.High speed requirements:

Unloading to maintain production or logistics processes.High labor costs:

In regions with high labor costs, automation can significantly reduce operating expenses.Labor shortages:

When there is a shortage of qualified workers to perform depalletizing tasks.Hazardous conditions:

When working with heavy, bulky, toxic, or dangerous loads that may pose a risk to worker health.Minimization of errors:

Automation helps reduce the number of errors associated with human factors.Scalability:

The ability to easily scale operations when production or logistics volumes increase.Warehouse automation:

When integration with other automated warehouse systems, such as conveyors, palletizing robots, packaging robots, and ERP systems, is necessary.

How to integrate a depalletizing robot?

To begin the process of automating depalletizing, you need to prepare a technical specification that should include the type of products, volumes, types of pallets, stacking specifics, current and desired depalletizing speed. This can be done either independently or by filling out a questionnaire with our specialist. Then we initiate the process of developing and implementing the depalletizer in stages:

1. Assessment of the technical specification for feasibility of automation.

We evaluate whether the desired result can be achieved with a robot;2. Selection of necessary equipment.

We select the equipment based on the task, budget, and customer experience.3. Presentation, approval, and signing of the contract.

We conduct a presentation of the solution we developed, agree on the terms, and sign the contract.4. Procurement, production, supply.

We procure equipment and components, manufacture the gripper and other kit elements, and develop connection schemes.5. Delivery and implementation.

We deliver the ready depalletizing complex, conduct supervisory installation, and integrate it into production.6. Commissioning and training.

We commission the complex and train the staff.

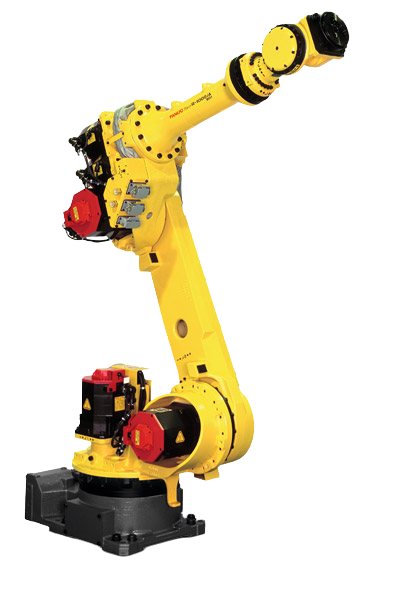

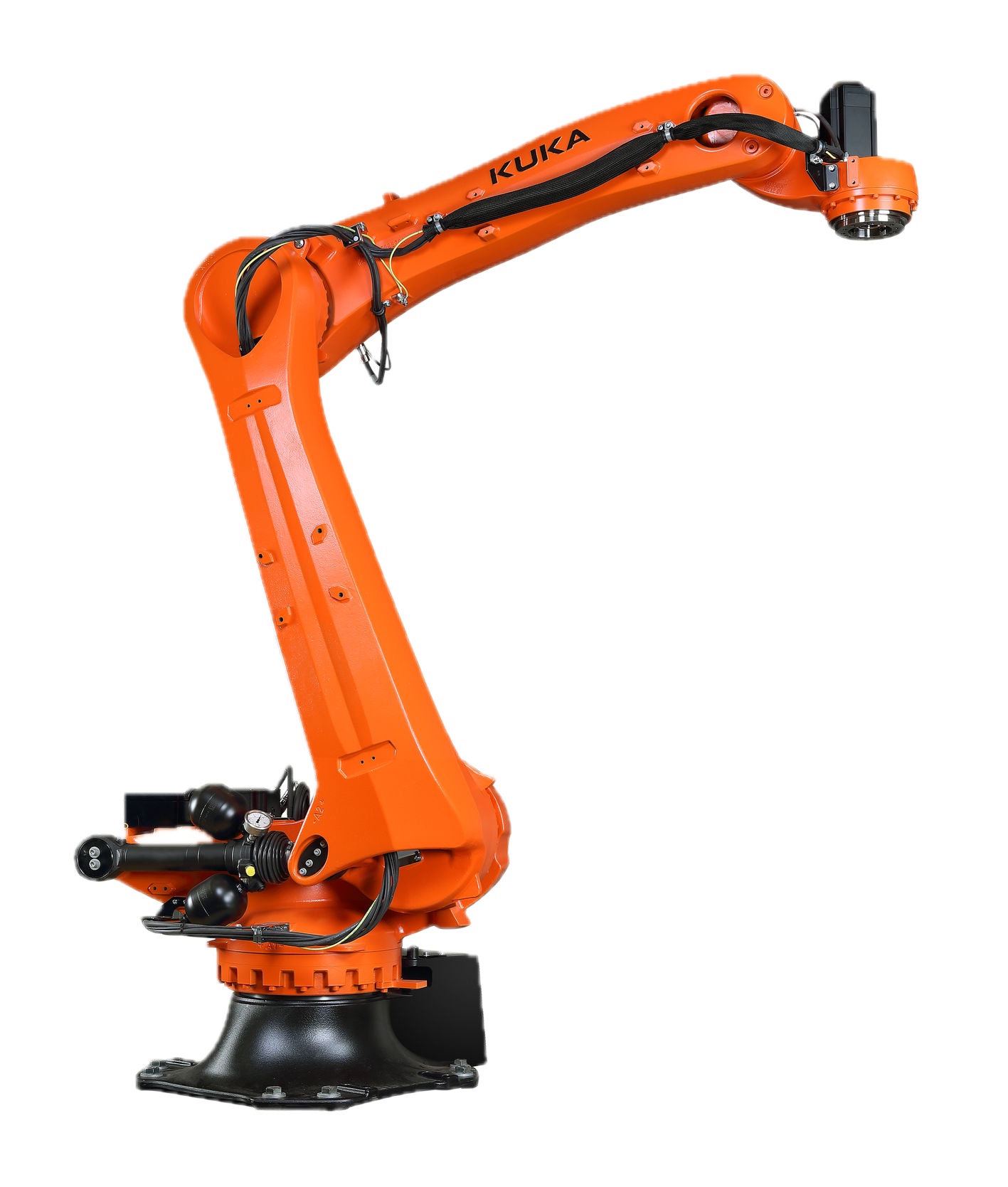

Depalletizing Robots

Benefits of implementing a depalletizer

Increased productivity:

Depalletizing automation allows for a significant increase in the volume of processed products;Reduction in labor costs:

Less need for manual labor leads to lower labor costs;Improvement in quality and accuracy:

Robots operate with high precision and repeatability, reducing the amount of defective and damaged products;Increased safety:

Eliminating human involvement in hazardous and heavy tasks reduces the risk of injuries in production.

Contacts

35th floor, 33/4, Tower A Rama 9 Road, Huaykwang Sub-district, Huaykwang district, Bangkok, 10310

Mon – Fri:

9 AM–8 PM

![[Alt]](/images/logo-min.png)