Robotic Solutions for any task

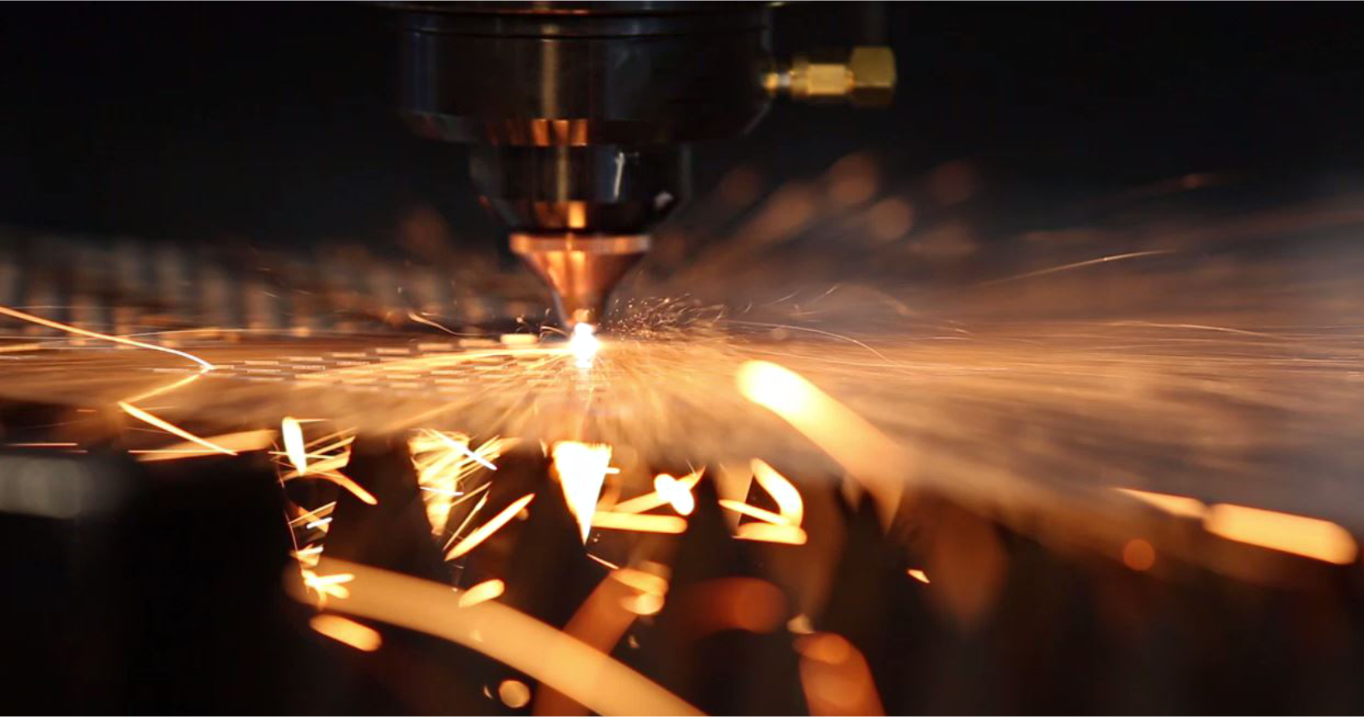

Integration of robotized solutions into production processes has long become the norm in numerous industries around the world. Robots have unquestionable proved their effectiveness as tools for achieving various tasks, whether it is raising safety standards, improving the quality and speed of production, or performing highly specialized and technically complex work.

Pick a task:

Palletizing robot at your company: more income due to high speed and accuracy of work. These can be parts, closed and open boxes, bags with any contents – different in weight and dimensions. More

Automation of pallet unloading processes to increase efficiency and speed, ensure labor safety, and reduce manual labor costs. More

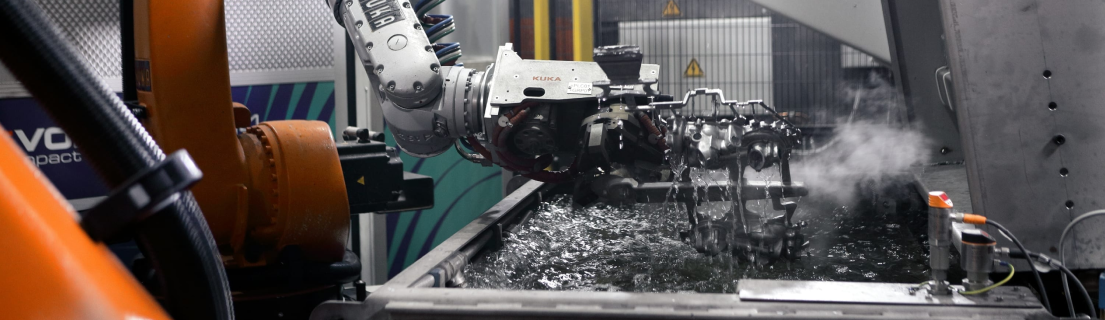

Robotization of machine servicing involves "smart" monitoring of the CNC machine and other equipment during operation, automation of the processes of loading workpieces and unloading finished parts. More

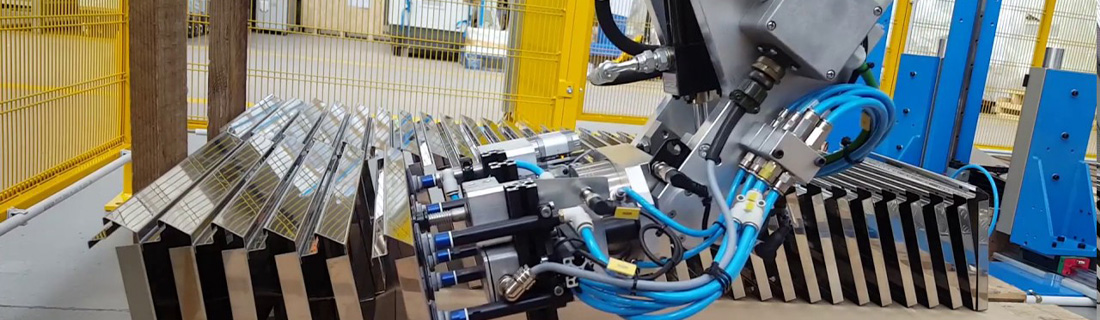

The robotization of the material transfer system is crucial for increasing the speed and volume of production, which in the long term leads to a reduction in costs and an increase in profits. More