![[Alt]](/upload/iblock/89f/i3233eqtknga8rhjdop5az2454x2q5h7.png)

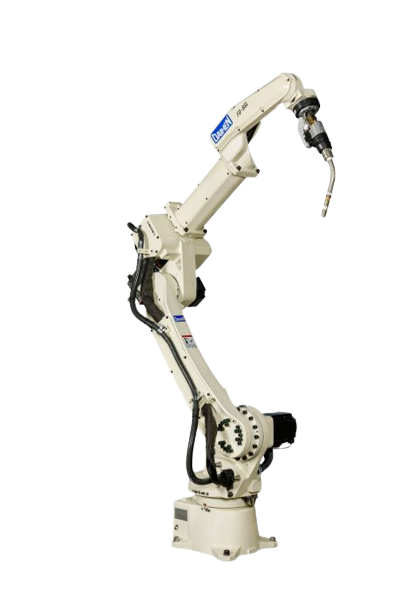

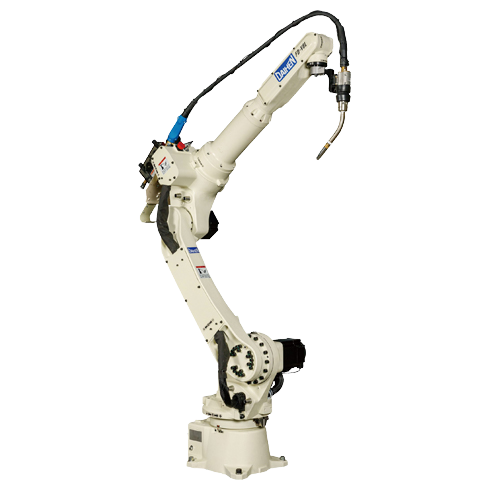

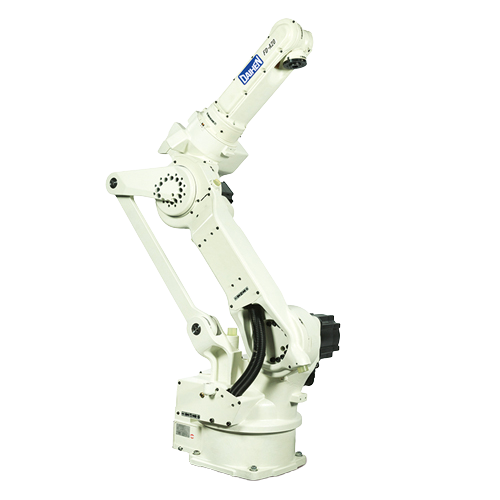

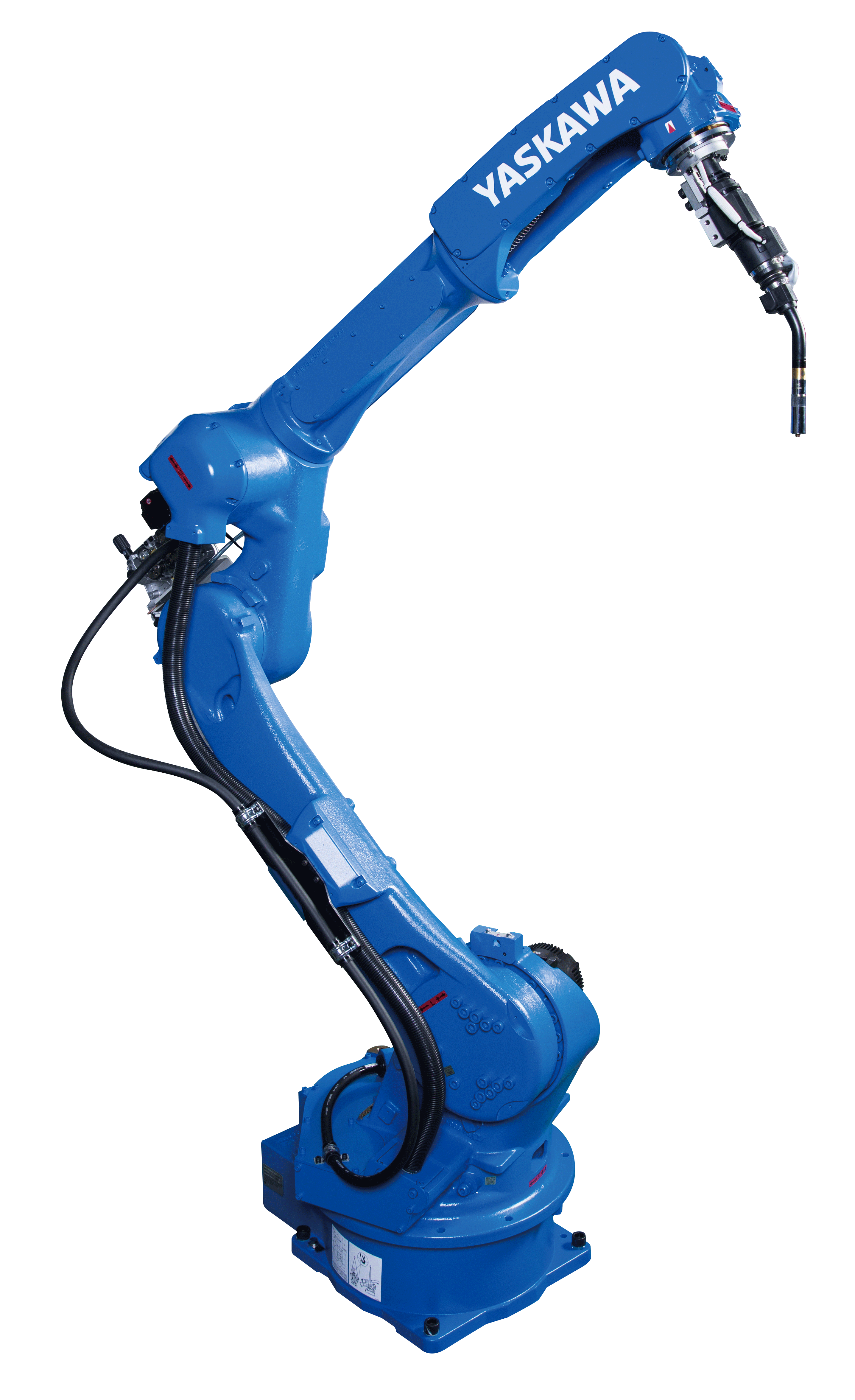

Robotic in Shipbuilding industry

High-speed industrial robots, together with automated production lines and high-precision measuring instruments in shipbuilding, are a cost-effective innovative solution that enable the manufacturer to reduce production costs, and increase the speed and quality of ship construction.![[Alt]](/upload/iblock/6aa/m1tueh1k2pr0gynja4r40un6mig1e7w2.jpeg)

For example:

The Korean shipbuilding company, Daewoo Shipbuilding, uses a robot weighing 16 kg to weld steel sheets in the production of ice-class gas carriers. Thanks to robotization, the cost of producing one ship has decreased to 4.5 billion KRW.Robots in shipbuilding

Industrial robots in shipbuilding are used for:metal cutting

bending

welding steel plates

quality control

painting

cargo movement

round the clock monitoring and control of technological processes

Contacts

35th floor, 33/4, Tower A Rama 9 Road, Huaykwang Sub-district, Huaykwang district, Bangkok, 10310

Mon – Fri:

9 AM–8 PM

![[Alt]](/images/logo-min.png)