![[Alt]](/upload/iblock/89f/i3233eqtknga8rhjdop5az2454x2q5h7.png)

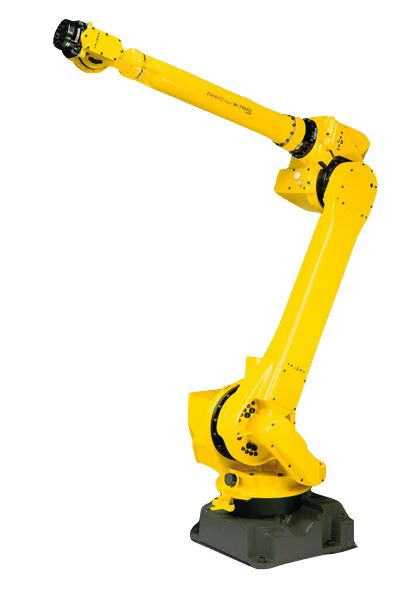

Robotic in heavy industry

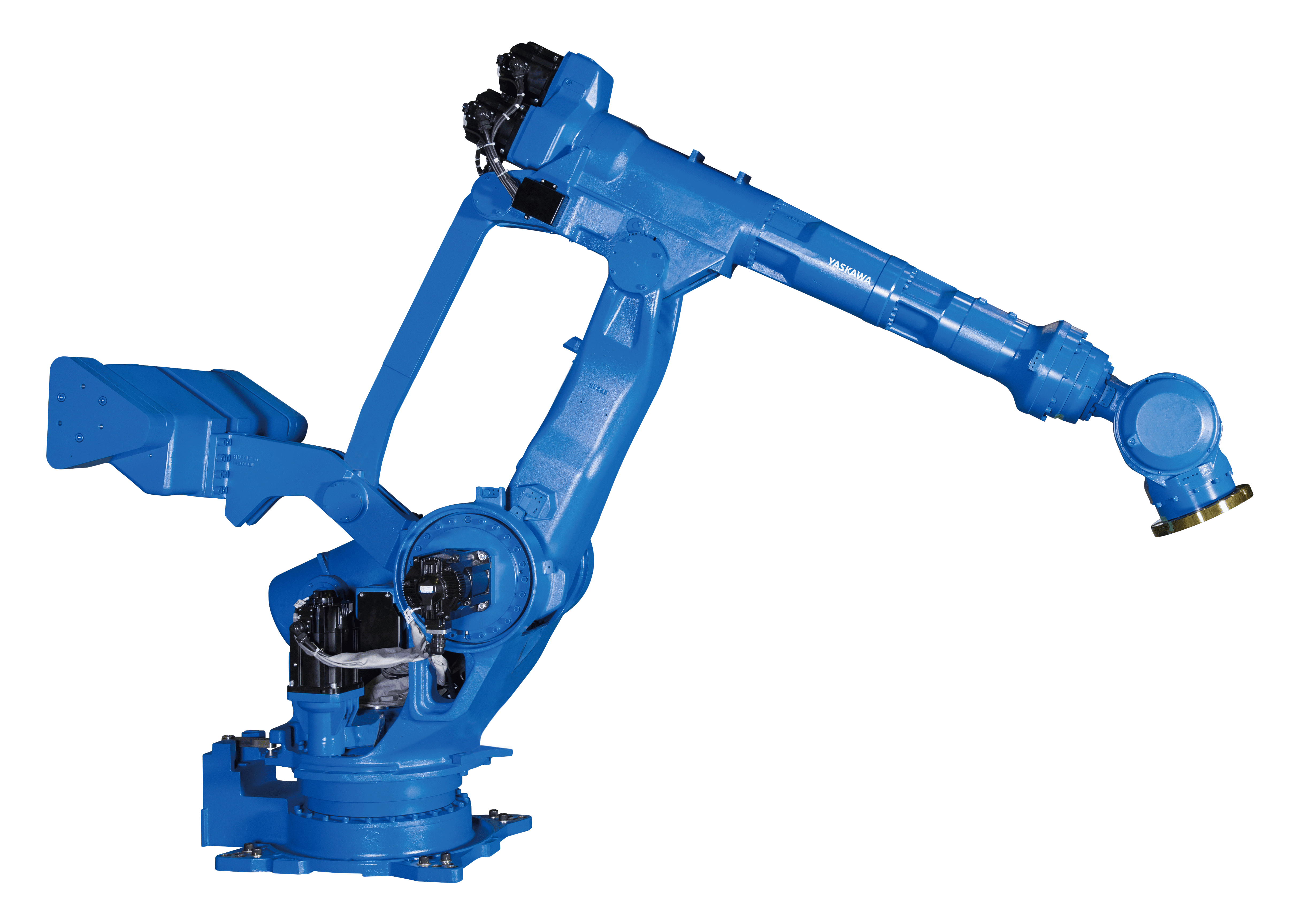

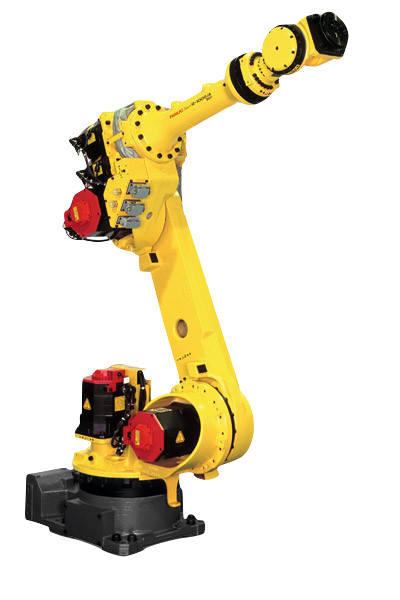

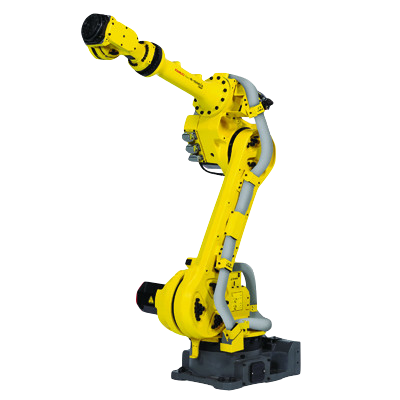

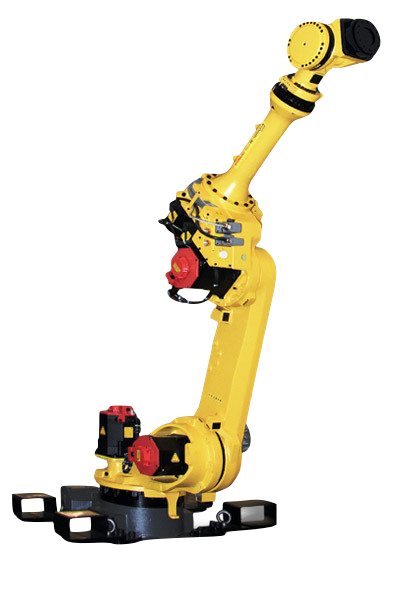

Robots in heavy engineering increase the safety of the production process, free up concealed and irrationally used resources, improve manufacturing quality and productivity. Enterprises engaged in the heavy machinery industry are actively implementing robotic solutions due to increasing competition and constantly increasing requirements for their products.![[Alt]](/upload/iblock/ddb/ch7rujjinqjawcc0xkubwk6yd31jxd3z.jpeg)

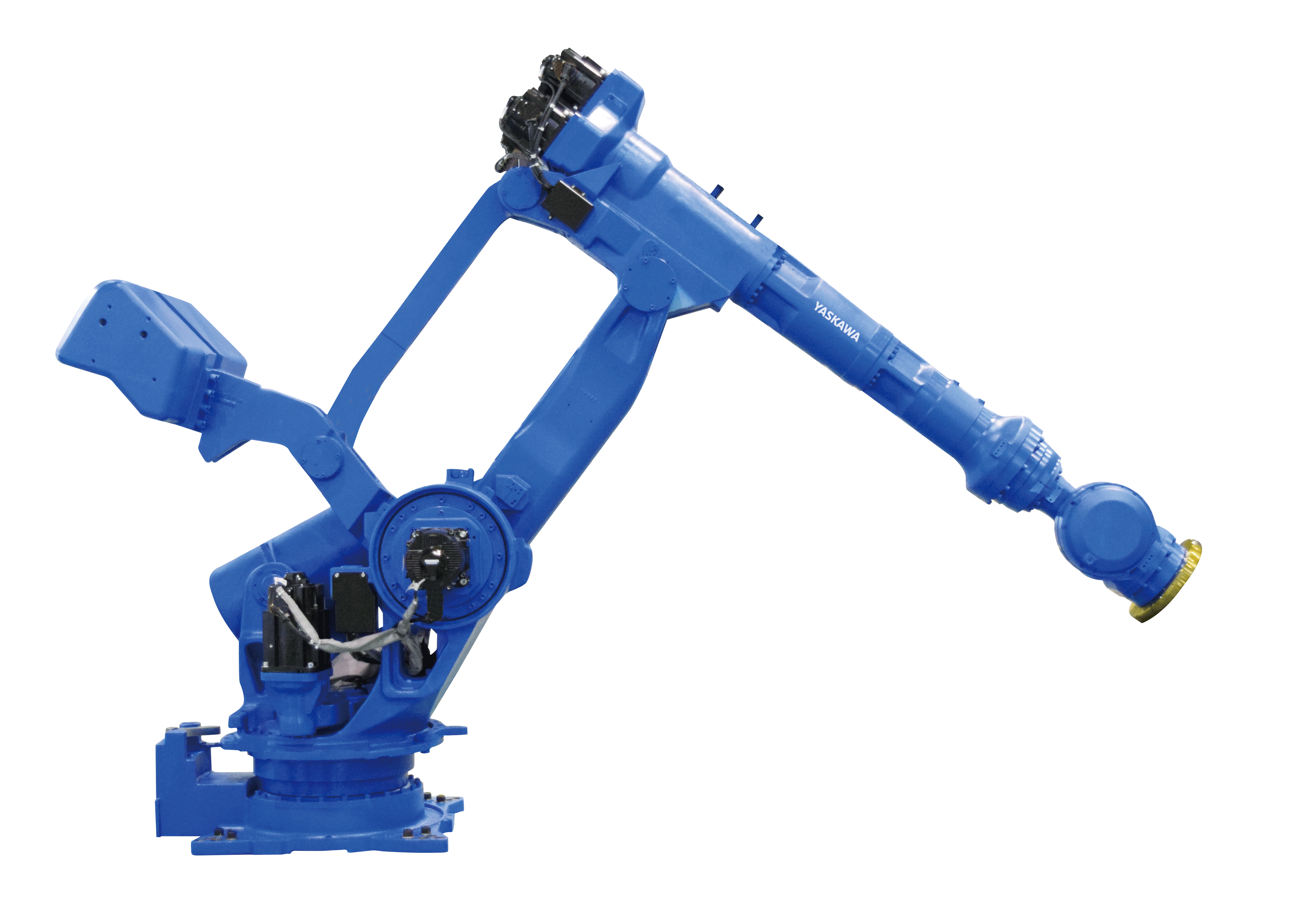

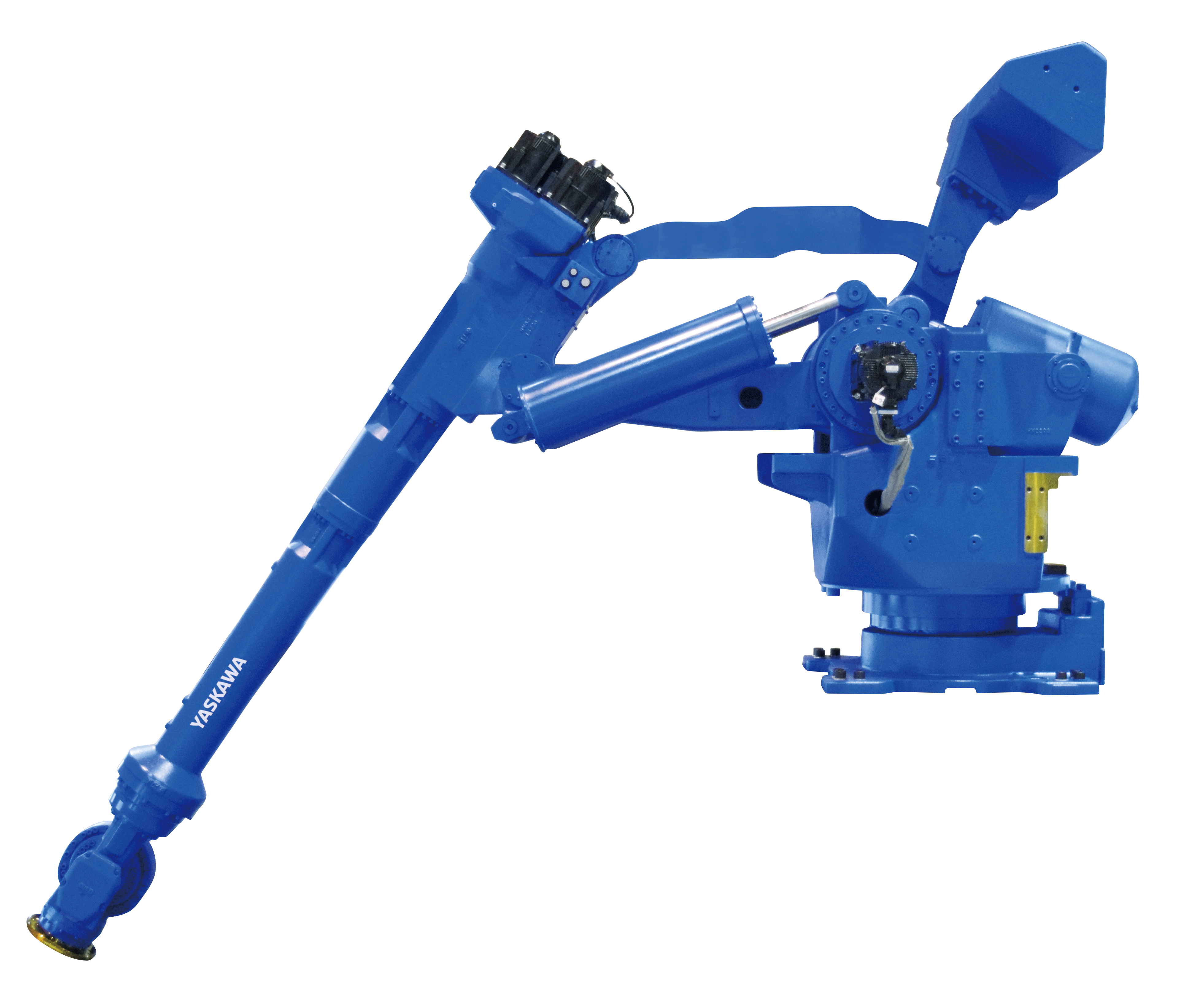

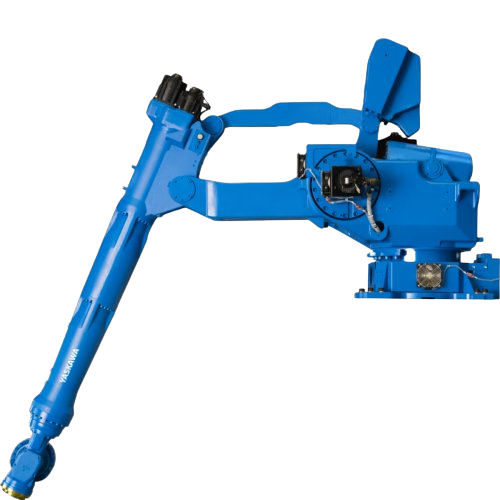

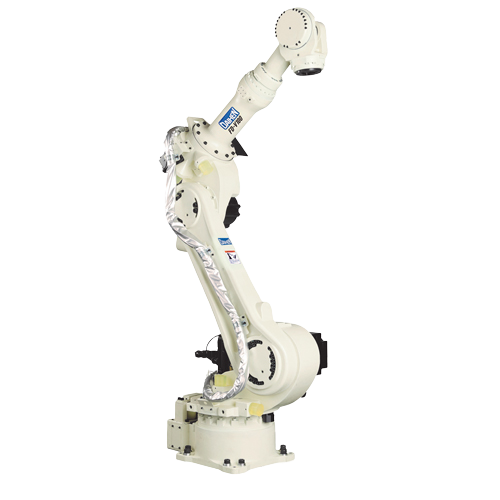

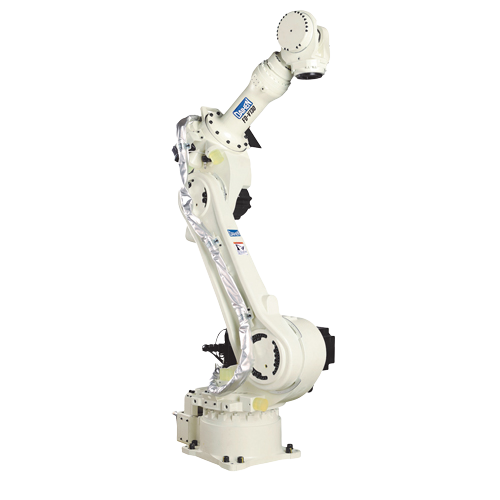

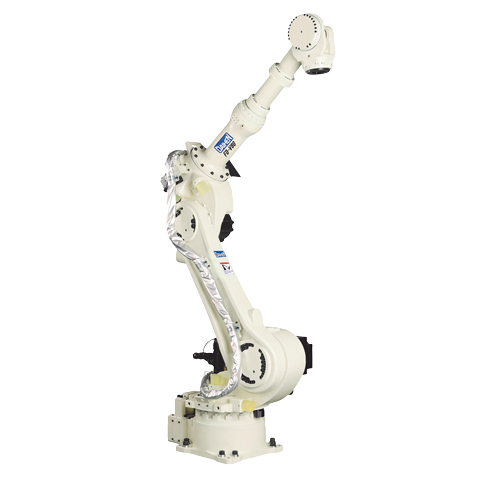

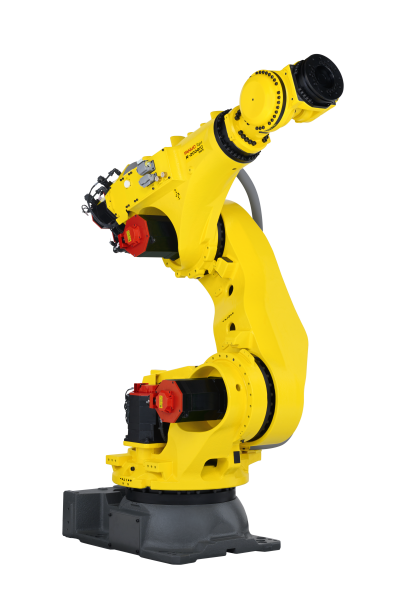

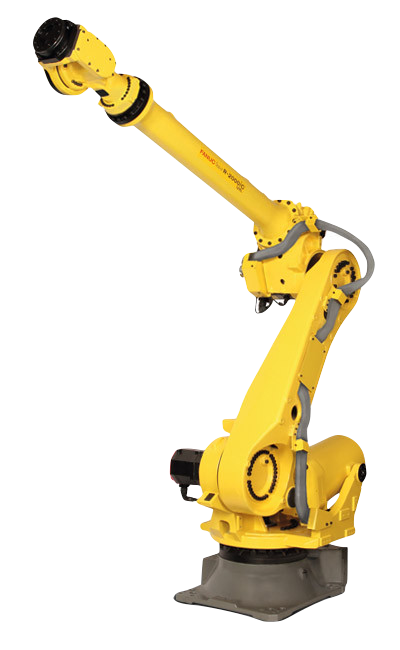

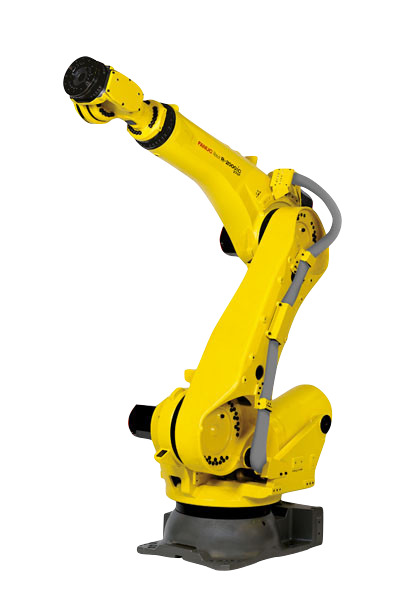

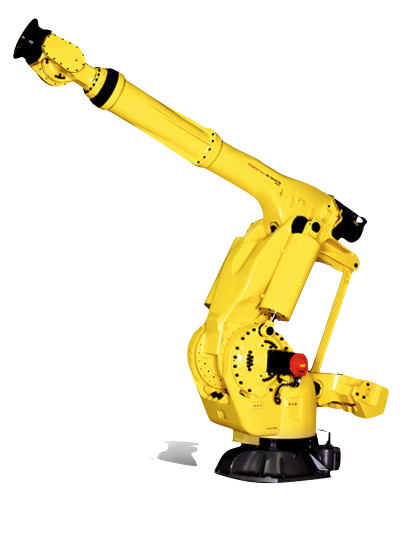

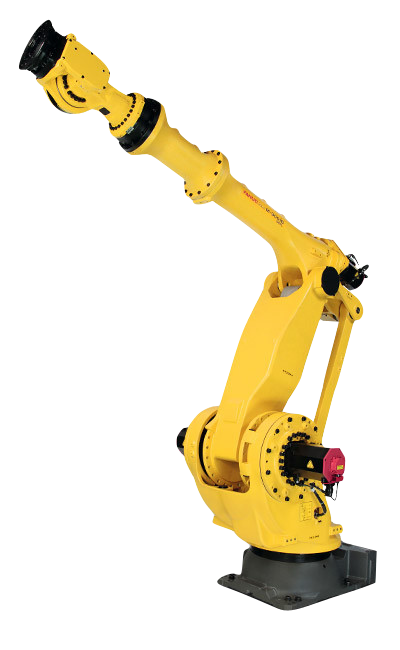

Robots in heavy engineering

High-speed industrial robots with various characteristics are capable of performing a wide variety of production tasks, such as

metal cutting

welding

milling

painting

palletizing

assembly

round-the-clock monitoring

and control of technological processes

Contacts

35th floor, 33/4, Tower A Rama 9 Road, Huaykwang Sub-district, Huaykwang district, Bangkok, 10310

Mon – Fri:

9 AM–8 PM

![[Alt]](/images/logo-min.png)