![[Alt]](/upload/iblock/89f/i3233eqtknga8rhjdop5az2454x2q5h7.png)

Robotic in Metal industry

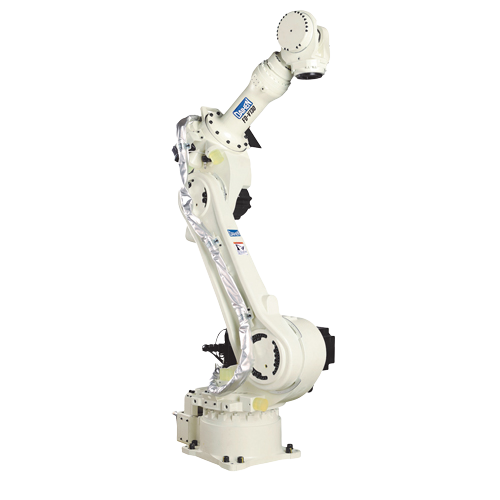

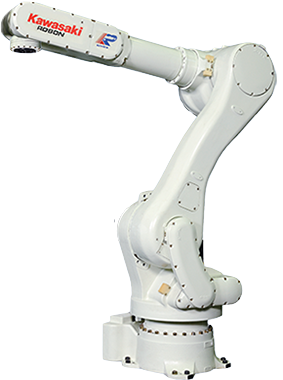

Total robotization in metallurgy and complete replacement of human labor in steelmaking workshops are the realities of the near future. Already, high-speed "smart" robots can replace human labour in many technological operations of ferrous and non-ferrous metallurgy industries![[Alt]](/upload/iblock/474/5nu6e06ci1k1pzr56t3tsmk104tykj1n.jpeg)

Robots in metallurgy

Manufacturers can increase energy efficiency and productivity, reduce costs, and optimize the economic performance of enterprises in the metallurgical sector with the help of modern innovative technology.

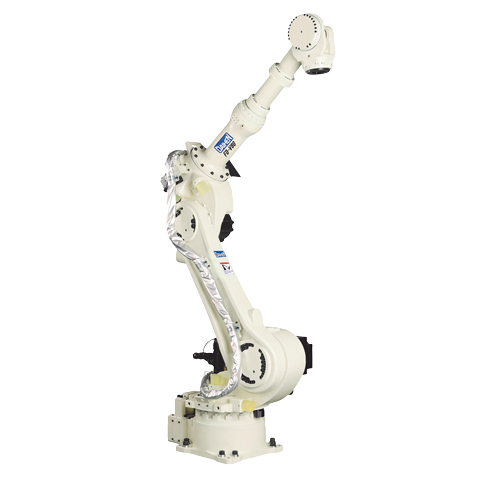

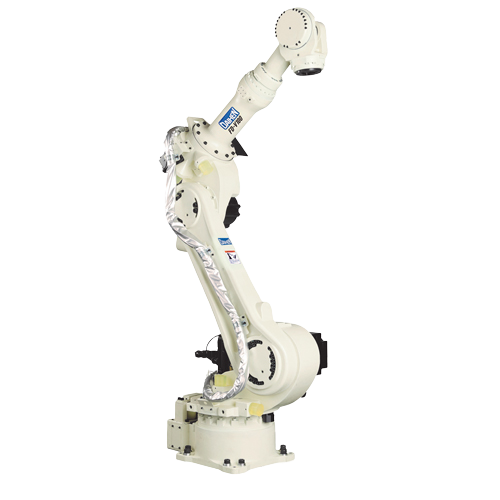

These operations are performed by industrial robots:

- sand casting, injection molding, welding, hot and cold stamping, milling, metal cutting, painting, spraying, labeling, packaging, palletizing, loading;

- sampling and measurement of the temperature of liquid steel, measurement of the metal level in the converter, delay and loading of slag;

- servicing of CNC machines.

Contacts

35th floor, 33/4, Tower A Rama 9 Road, Huaykwang Sub-district, Huaykwang district, Bangkok, 10310

Mon – Fri:

9 AM–8 PM

![[Alt]](/images/logo-min.png)