![[Alt]](/upload/iblock/3fb/o1cwy2qpuxgnvdt4m1mv2vk2nl2sjv5c.png)

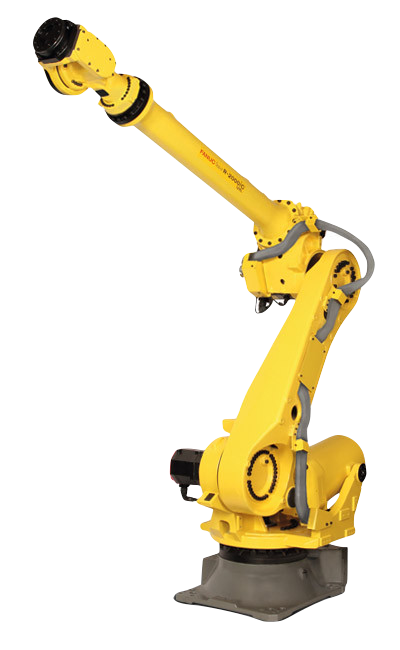

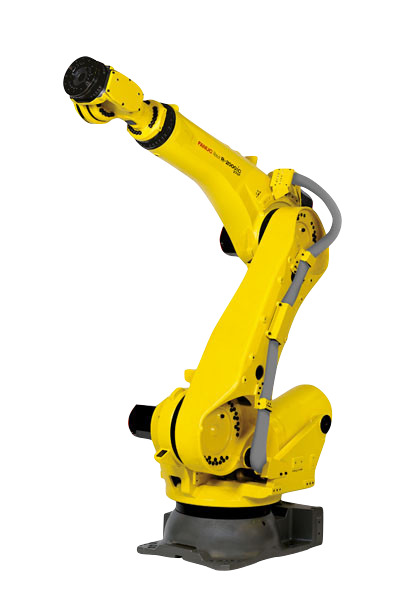

Robotic Cladding Solutions

Robotic cladding solutions are modern automated systems that use robots to apply metal coatings to the surfaces of various products. These technologies significantly enhance the quality, precision, and speed of cladding operations, making them indispensable in today's industrial environment.-

40%increase in

productivity -

60%reduction in

production

costs -

0.01mm robotic

cladding

precision -

30% material

saving

![[Alt]](/upload/iblock/b00/he8fbtfcx70po59k1loqvci0an3shnvb.png)

Industries

Robotic cladding systems are widely used across various industries:

Aerospace:

Robots are used to restore and strengthen critical engine components.Shipbuilding:

Robotic cladding solutions are employed in repairing and protecting ship hulls from corrosion.Oil and Gas Industry:

Robotic systems are used to restore worn-out parts of drilling equipment.Metallurgy:

Cladding robots are utilized in the production and repair of expensive shafts, rotors, and other large metal structures.

Types of Robotic Cladding

There are several types of robotic cladding, each utilizing different methods and technologies to apply coatings to various materials. Here are the main types:

Robotic Arc Cladding

Uses an electric arc to melt metal powder or wire, which is then applied to the surface of the product.Robotic Laser Cladding

A laser beam is used to melt the material, allowing for high precision and minimal deformation of the product.Robotic Plasma Cladding

The use of plasma for cladding enables reaching high temperatures, which is especially effective for processing hard and wear-resistant materials.Robotic Cladding with Additive Manufacturing (3D Printing)

Involves the use of robotic systems to layer material, enabling the creation of complex geometric shapes.

Challenges Addressed by Robotic Cladding Systems

Robotic cladding solutions can be effectively applied to address the following challenges:

- Restoration of Worn Parts: Extending the lifespan of equipment.

- Corrosion and Wear Protection: Applying protective coatings to critical components.

- Manufacturing Complex Parts: Creating unique geometric shapes with high precision.

Advantages of Implementing Robotic Cladding Solutions

Robotic cladding systems are suitable for enterprises aiming to automate and increase production efficiency. These include large industrial companies in metallurgy, mechanical engineering, energy, and other industries where high precision and reliability in material processing are required.

- Improved Product Quality: Achieved through the high precision and consistency of robotic operations.

- Reduced Operating Costs: Lower material consumption and process optimization.

- Minimized Human Error: Reducing the number of mistakes and defects.

- Increased Competitiveness: By leveraging advanced technologies and enhancing productivity.

Contacts

35th floor, 33/4, Tower A Rama 9 Road, Huaykwang Sub-district, Huaykwang district, Bangkok, 10310

Mon – Fri:

9 AM–8 PM

![[Alt]](/images/logo-min.png)