What is a collaborative robot (cobot)?

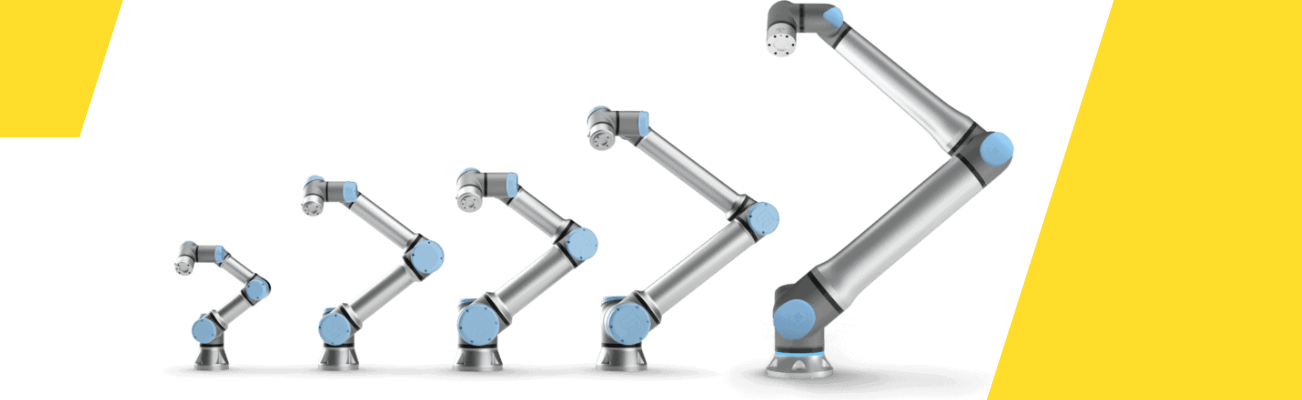

Collaborative robots, or cobots for short, are one of the most innovative technologies in the field of manufacturing automation. They are robots that can safely work alongside humans, collaboratively performing various tasks.

The main idea behind collaborative robots is to combine the best qualities of humans and robots to achieve greater productivity. Humans possess intelligence and flexibility, while robots possess precision and speed. Cobots combine these qualities, allowing them to perform complex and repetitive tasks, freeing humans from monotonous work and increasing production efficiency.

Collaborative robots, or cobots for short, are one of the most innovative technologies in the field of manufacturing automation. They are robots that can safely work alongside humans, collaboratively performing various tasks.

The main idea behind collaborative robots is to combine the best qualities of humans and robots to achieve greater productivity. Humans possess intelligence and flexibility, while robots possess precision and speed. Cobots combine these qualities, allowing them to perform complex and repetitive tasks, freeing humans from monotonous work and increasing production efficiency.

How are collaborative robots different from industrial robots?

The main difference between a collaborative robot and an industrial robot is that cobots can work alongside humans in shared workspaces, while industrial robots work in separate safety zones behind barriers and with the use of various safety sensors. Cobots are already equipped with sensors and safety systems that allow them to detect the presence of humans and stop when necessary. They are also much more flexible and versatile, easily reassignable to different tasks and equipped with various tools and attachments. Unlike industrial robots, which often perform repetitive and routine tasks, cobots can perform more complex and diverse tasks, freeing humans from monotonous work.

What are the advantages of collaborative robots?

The advantages of collaborative robots include:

-

Safety:

Cobots are equipped with sensors and safety systems that allow them to work alongside humans without risking their health and lives.

-

Flexibility and versatility:

Cobots can be easily reassigned to different tasks and equipped with various tools and attachments, making them much more flexible and versatile than industrial robots.

-

Efficiency:

Cobots can work together with humans, performing various tasks in parallel or interacting with each other, which increases production efficiency.

-

Cost reduction:

Cobots can be more cost-effective to use than industrial robots, as they do not require separate workspaces and can operate without the need for special maintenance.

-

Improvement of working conditions:

Cobots can perform heavy and dangerous tasks, freeing humans from monotonous and tiring work and improving working conditions.

-

Ease of training:

Cobots can be easily programmed and trained for new tasks, making them accessible for use in various industries and productions.

What tasks are collaborative robots used for?

-

Welding

-

Soldering

-

Gluing and sealing

-

Testing and quality inspection

-

Palletizing

-

Machine tending

-

Bin picking

-

Pick and place

-

Packaging

-

Assembly

-

Researching

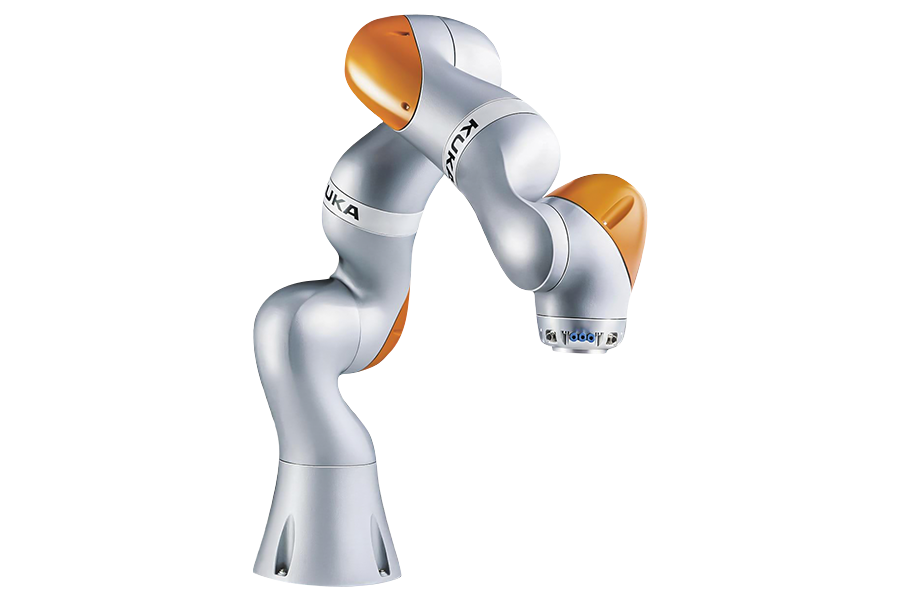

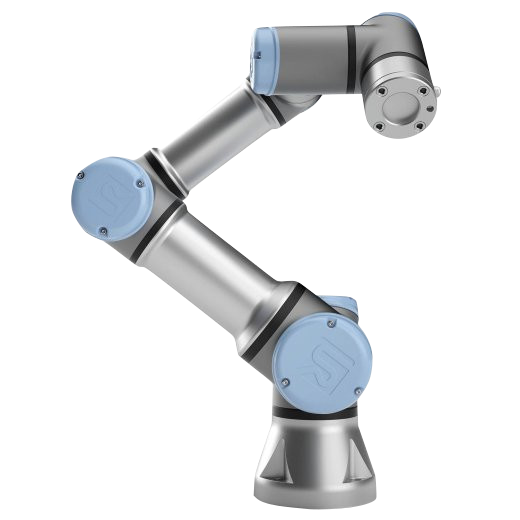

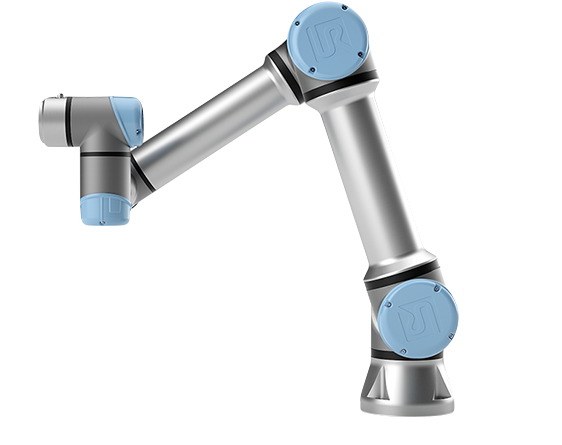

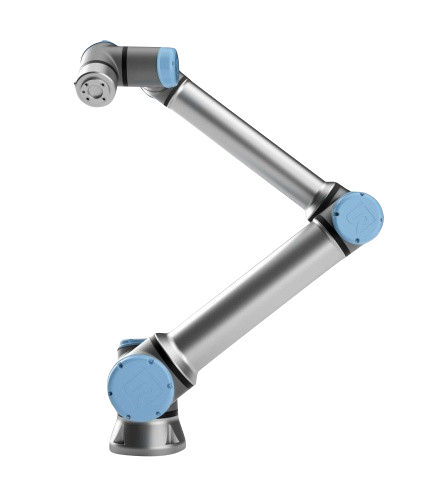

Main types of collaborative robots

International standards ISO 10218 divide cobots into 4 types:

-

1. Safety Monitored Stop:

these cobots are equipped with special safety sensors that react to a person entering the robot's workspace and stop at that moment. The cobot will continue executing the program only when the person leaves the robot's workspace.

-

2. Speed and Separation:

this type of collaborative robots is similar to Safety Monitored Stop, but uses more advanced vision systems, and when a person approaches the working cobot, it slows down its movement and completely stops when the person gets too close to the robot.

-

3. Power and Force Limiting:

this type of collaborative robots has rounded corners and a set of intelligent collision sensors that quickly detect contact with a person and stop program execution. Such cobots have force limitations to ensure that any collisions do not result in injuries.

-

4. Hand Guiding:

these collaborative robots are equipped with a device for manual control, through which the operator controls the movement of the robot by moving their hand to the necessary points.

In general, collaborative robots represent a safer, more flexible, and efficient alternative to industrial robots, capable of improving working conditions and increasing productivity in various application areas.

Despite all the advantages, the use of collaborative robots does not mean replacing humans in production. On the contrary, they can become indispensable assistants to humans, performing heavy and dangerous work, as well as freeing up time for more creative tasks.

In conclusion, collaborative robots are an innovative technology that can significantly improve production efficiency and safety. They combine the best qualities of humans and robots, allowing them to perform various tasks alongside humans. Cobots have already found wide application in various industries and will undoubtedly continue to evolve and improve in the future.

![[Alt]](/images/logo-min.png)