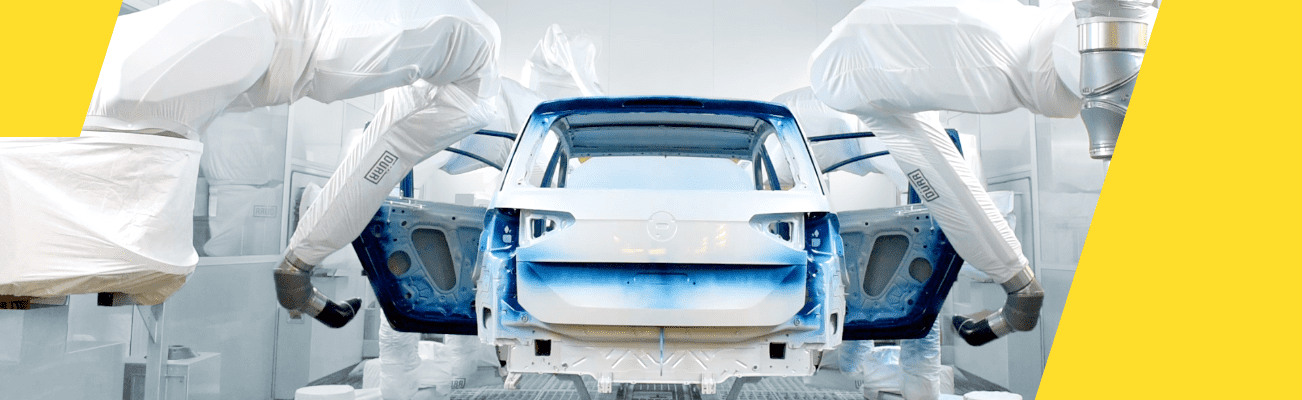

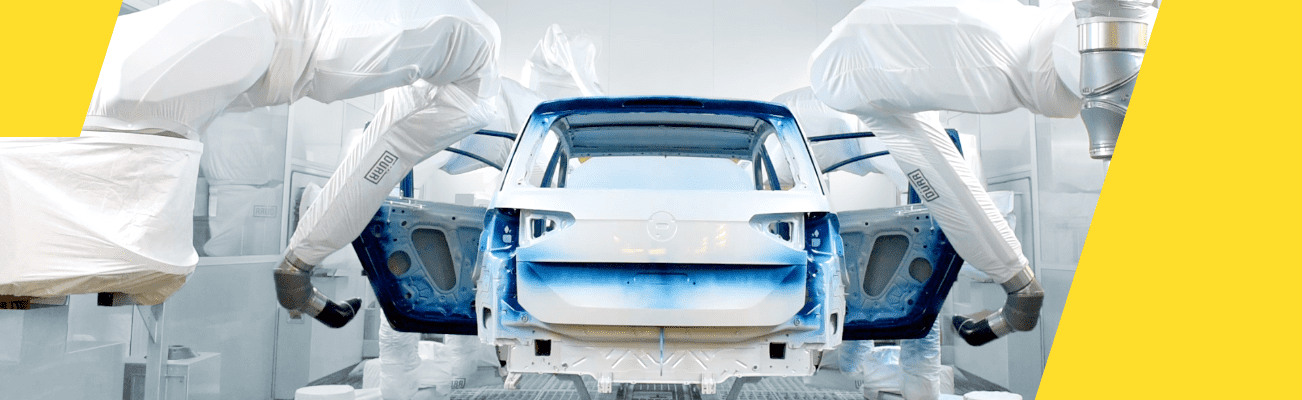

The automation of the painting process. What is painting robot?

In the modern world, where automation and robotics play an increasingly important role in various industries, painting robots have become an integral part of the production process. Robotic painting offers a number of advantages, such as improved coating quality, increased productivity, and reduced labor costs. In this article, we will discuss the key aspects of robotic painting and its prospects.

In the modern world, where automation and robotics play an increasingly important role in various industries, painting robots have become an integral part of the production process. Robotic painting offers a number of advantages, such as improved coating quality, increased productivity, and reduced labor costs. In this article, we will discuss the key aspects of robotic painting and its prospects.

What is a painting robot?

A painting robot is an automated system capable of applying paint to surfaces without human involvement. It is equipped with special mechanisms and software that allow for precise and uniform application of paint to objects of various shapes and sizes. Painting robots have high accuracy, stability, and can control the thickness of the applied paint layer, ensuring high-quality coating. They are also capable of working much faster than humans and do not require breaks or rest.

Painting robots consist of the following components:

-

Robotic arm: designed for movement and control of the paint gun or other painting tools.

-

Paint gun: a device that sprays paint onto the surface of the object. The paint gun can be pneumatic, electric, or hydraulic.

-

Paint delivery system: includes a reservoir for storing paint and pumps or valves to deliver paint to the paint gun

-

Sensors and cameras: used to detect the surface of the object, determine its size and shape, and control the thickness of the applied paint layer.

-

Software: allows for control of the robot's operation, setting parameters for paint application, and monitoring the painting process.

Advantages of a painting robot:

-

High precision and quality of work: A painting robot is capable of performing work with a high degree of accuracy and repeatability, ensuring even paint application on the surface of the object and avoiding streaks or unevenness.

-

Speed and efficiency: The robot can work continuously without the need for breaks for rest or food. This reduces painting time and increases productivity.

-

Improvement of working conditions: A painting robot relieves the operator from heavy physical labor and the harmful effects of paint on the body. This improves working conditions and reduces the risk of occupational diseases.

-

Resource savings: The robot uses paint more efficiently, minimizing losses and excessive application. This reduces paint expenses and decreases waste generation.

-

Flexibility and adaptability: A painting robot can be configured to work with different types of surfaces and materials, as well as perform various types of painting (e.g., single-color or multi-color). This provides flexibility in production and the ability to adapt to different requirements and orders.

-

Improvement of quality and reliability: The robotic system allows for control and adjustment of paint application parameters, enhancing the quality and reliability of the painting process. This is especially important when working with complex shapes or surfaces.

Overall, a painting robot offers a more efficient, accurate, and cost-effective solution for performing object painting tasks. All these components work together to provide automated and precise painting of objects without human involvement.

What coatings can a painting robot spray?

A painting robot can apply various types of coatings, including:

-

Paints: Painting robots can apply different types of paints, including acrylic, enamel, latex, and epoxy paints.

-

Varnishes: Painting robots can apply different types of varnishes, including transparent, glossy, and matte varnishes.

-

Powder coating: Painting robots can apply powder coating, which provides a durable and long-lasting coating on metal surfaces.

-

Anti-corrosion coatings: Painting robots can apply special coatings that protect the surface from corrosion and oxidation.

-

Thermal insulation coatings: Painting robots can apply thermal insulation coatings that improve the heat-insulating properties of the surface.

The automation of the painting process has great potential and is a promising direction for enterprises that currently perform manual painting. With the development of technology and artificial intelligence, painting robots are becoming smarter and more flexible. They can adapt to different types of surfaces and working conditions, expanding their range of applications. Furthermore, robots can be integrated into automatic control and monitoring systems, allowing for remote control and optimization of the painting process.

However, despite all the advantages of automating the painting process, there are also some limitations. Firstly, the high cost of purchasing and installing painting robots can be a significant factor limiting small businesses. Secondly, robots require specific working conditions, such as a clean environment and special equipment, which may be difficult to provide in certain production settings.

In conclusion, the automation of the painting process and the use of painting robots offer numerous benefits for enterprises. They improve coating quality, increase productivity, and reduce labor costs. With the advancement of technology, even greater expansion of the application scope and capabilities of painting robots is expected.

![[Alt]](/images/logo-min.png)