Industrial robots. Advantages of use.

Industrial robots are devices used to automate production processes and increase the efficiency of enterprises. They can perform various tasks such as welding, cutting, assembly, packaging, etc., which helps to reduce production time and improve product quality.- One of the main advantages of using industrial robots is increased labor productivity. Thanks to the automation of work processes, people can focus on more important tasks, such as equipment management or quality control. This can also lead to a reduction in labor costs.

- In addition, industrial robots can be used to perform tasks that were previously inaccessible to humans due to complexity or danger. For example, they can be used for assembling complex parts or packaging finished products.

Industrial robot applications.

Industrial robots are used in many industries to automate various production processes. The most common tasks where industrial robots are used include:

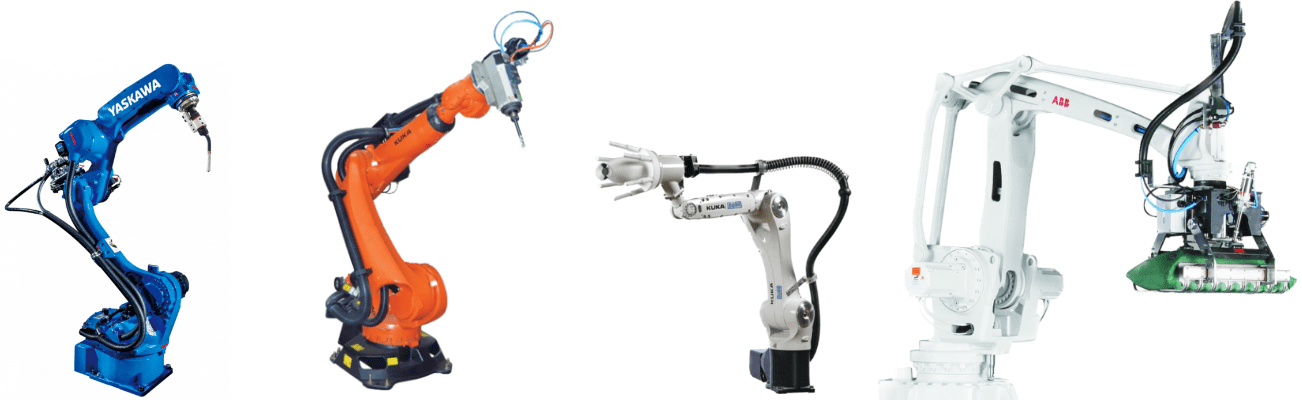

- Welding: Robots can be used for automatic welding of metal products. This helps to speed up the welding process and reduce errors related to human factors.

- Cutting: Robots can be used for cutting metal materials into parts of the required shape and size. This is especially useful in the production of automobiles, airplanes, and other large products.

- Assembly: Robots can be used for assembling complex products from multiple components. This is particularly important in the production of electronics, medical devices, and other high-tech products.

- Packaging: Robots can be used for packaging finished products in containers of the required size and shape. This helps to improve logistics efficiency and reduce packaging costs.

- Quality control: Robots can be used for checking the quality of products before they are shipped to customers. This allows for detecting defects before the products reach store shelves.

- Milling: Robots can be used for precise and fast milling of various materials such as metals, plastics, wood, and others. This significantly speeds up the processing process and improves the quality of the resulting products.

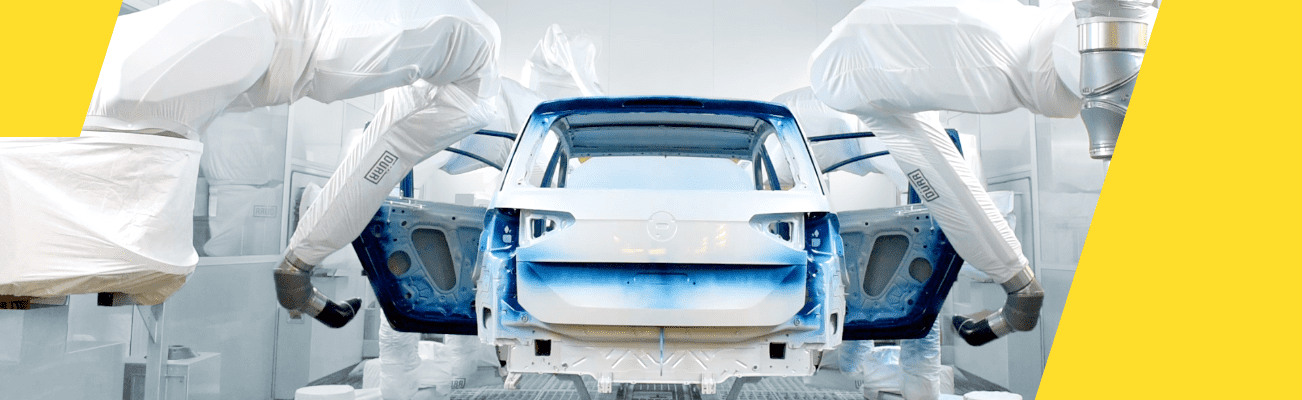

- Painting: Robots can be used for painting metal surfaces, glass, walls, and other surfaces. This helps to speed up the painting process and improve the quality of the resulting products.

- Palletizing and depalletizing: Robots can be used for palletizing and depalletizing various types of cargo, including heavy metal sheets, plastic bottles, bags, or boxes of products.

Increasing production volumes and growing quality requirements will contribute to an increase in demand and the development of robotic solutions. The development of robotic solutions will allow for the automation of new processes that were previously considered almost impossible to automate.

You can start robotization today by contacting Robotec specialists, and we will find the optimal solution for automating your tasks.

![[Alt]](/images/logo-min.png)