Palletizing is the final stage of the production process and is often a bottleneck on the production line. The robot palletizer helps not only to unload the bottleneck, take control and accurately predict the number of pallets stacked per unit of time, but also to get away from manual labour by automating the heavy monotonous work of stacking products on pallets.

What is a robot palletizer?

A palletizer robot is a 4-axis industrial robot with a special gripping tool for moving objects from the conveyor to the pallet. The same type of robots is used in the opposite process of unloading products from a pallet onto a conveyor, but they are called depalletizer robots. Palletizer robots have 4 axis, since when palletizing an object is shifted from one plane to another parallel to the first. The 5th and 6th axis in robots are used for flipping objects, which is not used in palletizing. Due to the smaller number of axis, palletizing robots are cheaper than 6-axis robots of equal load capacity. Most of the world's manufacturers complement palletizer robots with special palletizing software which simplifies program coding for the robot. The gripping tools for palletizer robots are determined by and developed for a specific type of palletizing object - a bag, box, bottle or something else.

How does the process of robotic palletizing work?

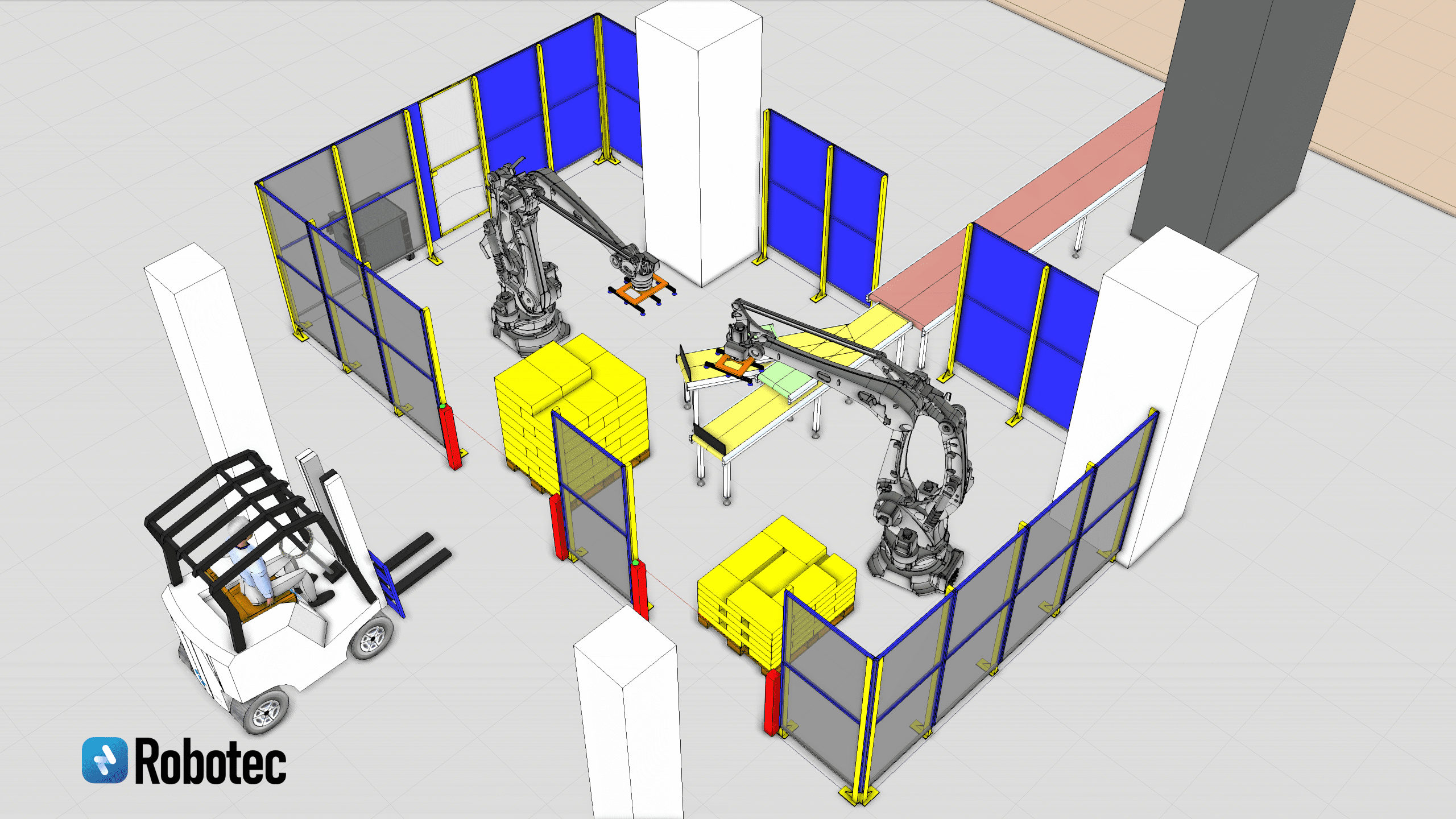

The robot captures the object at the end of the conveyor and moves it to the pallet and so on until it fills it according to the stacking schematic and the active program. The assembled pallet is taken away and is replaced by an empty one, the robot begins the stacking process anew. The feeding of empty pallets, pallet transportation and the wrapping of stacked pallets can also be automated to completely get away from manual labour. At the end of the conveyor, a sensor is installed that informs the robot that the object has arrived at the designated point and can be picked up. Another sensor informs that the pallet is in the right place and objects can be stacked there. The stacking schematic and object parameters are recorded in the program. Each type of object, pallet size and stacking scheme has its own program. To ensure safety, a fence and security sensors are installed around the palletizer robot, if someone crosses them, then the robot stops executing its running program immediately.

Which robots are commonly used for palletizing?

-

1. The 4-axis robot palletizer is used for most palletizing tasks of bags, boxes, bottles and other objects which require no flipping of the product when stacking on a pallet.

-

2. The 6-axis industrial robot is used for palletizing objects of complex shape that cannot be gripped from above and when the object needs to be turned over before being placed on a pallet.

-

3. The collaborative robot palletizer can be used for laying small objects in a limited space in other cases, this type of robot is inferior to the classic robot palletizer. It, however, does not require additional security sensors and fence as the robot will stop automatically by itself if it comes into contact with a person or another obstacle.

-

4. The gantry palletizer is a less flexible and cheaper option for palletizing and requires a lot of space for installation and is used for simple schematics of stacking products on a pallet.

The choice of a palletizer robot directly depends on the task, the type and weight of the manipulated object, the height of the assembled pallet, the speed and number of production lines serviced by the robot, the installation location. The task of selecting a suitable robot is undertaken by integrators.

Leave a request and we will find you a palletizer robot that help you improve your production.

![[Alt]](/images/logo-min.png)